What Is a Liquid Pump?

Liquid pumps are pumps used to supply and transfer liquids.

Liquid pumps can move liquids from low to high or from container to container.

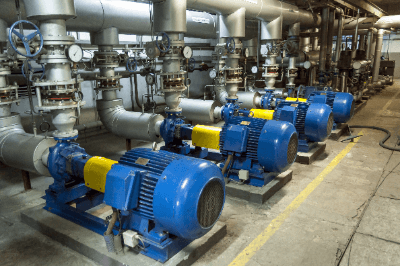

Pumps of various sizes and performances are used for a wide range of purposes, from household refueling pumps to large-scale factory production lines and drainage lines.

Uses of Liquid Pumps

Liquid pumps are used in many locations, such as:

- Household oil feed pumps (manual and electric)

- Equipment used in chemical experiments

- Medical fields (intravenous drips, dialysis machines, artificial heart-lung machines, etc.)

- Liquid transfer in food production lines

- Liquid transfer in pharmaceutical production lines

- Water supply and sewage facilities

- Sewage treatment facilities

- Factory wastewater transfer systems

Pumps come in a wide variety of structures and sizes depending on their usage.

Pumping liquid without leaking it outside is the basic performance requirement, but pumps with optimal characteristics are selected according to the intended use, such as for medical equipment where a certain amount of liquid must be injected within a certain period, or for pharmaceutical or food production lines where accurate metered dosing is required for a given process.

Principle of Liquid Pumps

The basic principle of operation is the same for all pumps: pumping liquid by repeating the “suction” → “discharge” process.

Liquid pumps are broadly classified into the following two types in terms of structure:

- Non-displacement Pumps

- Positive Displacement Pumps

Non-displacement pumps are constructed to move liquid by rotating an impeller inside an enclosure. They have the following characteristics:

- High-speed rotation can create a continuous flow.

- Suction and discharge pressures are relatively low.

- Capable of pumping large volumes of liquid, but the flow rate fluctuates depending on the nature of the liquid.

A positive displacement pump has a structure that moves liquid by changing the volume in a compartment (small room) inside the housing and has the following characteristics:

- High suction pressure and discharge pressure can be achieved.

- An accurate setting of discharge pressure and flow rate is possible.

- Liquid transfer volume is relatively small.

Volute pumps, axial flow pumps, and semi-axial flow pumps are classified as non-volumetric pumps.

The following types of positive displacement pumps are available:

- Types that perform suction and discharge using the linear motion of internal parts (piston pumps, plunger pumps, diaphragm pumps)

- Types that perform suction and discharge using the rotation of internal parts (gear pumps, rotary pumps, vane pumps)