What Is a Rotary Press?

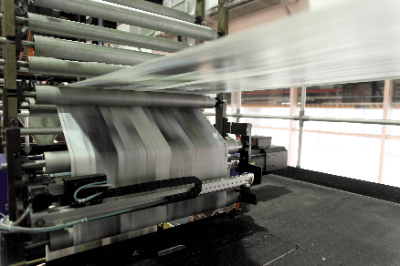

A rotary press is one of the printing presses in offset printing, capable of handling double-sided printing and multi-color printing at high speed. A roll of paper (take-up paper) is set, the printing plate is set in a rotating cylinder, and the paper is printed while being passed between the cylinders while being rewound on the other side of the press. This type of printing excels at printing large quantities of items, such as newspapers and flyers. After printing, the paper is cut to a predetermined size and finished. The printing press is very large. Rotary press printing is prone to paper shrinkage due to the use of a high-temperature dryer to dry the ink after printing. The size of the rolls that can be set is limited by the rotary press.

Rotary press printing presses that use cut sheets of paper are called sheet-fed presses, whereas rotary press printing presses use rolls of paper.

Uses of Rotary Presses

Offset printing is used for low-cost, high-volume printing and is often used to print magazines, newspapers, flyers, etc. with large circulation. Also used for posters, etc. Relatively thin paper is used. Special ink dries quickly with heat, so post-processing is unnecessary, and high-speed processing is possible by dryer processing at high temperatures after printing.

Principle of Rotary Presses

A roll of paper is set in the rotary press, and printing is performed while the roll passes between the blank and pressure cylinders. The printing plate (aluminum plate) is set in a part called the plate cylinder of the rotary press. Fountain solution and ink are applied to this plate, and once the ink is transferred to the blanket cylinder (blanket, a transfer roller made of resin or rubber), it is printed on the passing take-up paper. Printing is done in double-sided multi-color printing, which enables high-speed printing. To speed up ink drying, the rotary press uses heat-set ink, which dries rapidly with heat, and the ink is passed through a dryer section to dry. The hot paper is cooled by being wound onto cooled rollers in the cooling section that adjusts the tension of the web, and then the paper is folded and cut.

In a rotary press, the ink on the blank cylinder is transferred to the paper, so the paper and the plate do not come into direct contact with each other. This printing method is called offset printing. Since the plates do not touch the paper directly, there is less wear, and the long life of the plates also makes them suitable for high-volume printing.

Differences Between Rotary Presses and Copy Machines

Both rotary presses and photocopiers can reproduce originals, but each has its own advantages and disadvantages and is used for different purposes.

Copiers are generally for home and office use, with multifunction devices that include fax, printer, and scanner functions in addition to copying. They can be conveniently linked to a computer or network. Because the functions are integrated, they have the advantage of reducing equipment management costs and saving installation space. However, because they can print in full color, they are used for a wide range of purposes, including photo printing and the preparation of presentation materials.

A rotary press is not as multifunctional as a copier and is a dedicated printing machine that can print manuscripts at high speed, with one- or two-color printing being the most common type. They can print at more than 100 sheets per minute. Although it requires some space for installation and preparation such as setting up a rewinder and adjusting the machine, once a plate is made, ink is applied and the paper is crimped to print a large number of sheets, so the more sheets printed, the lower the unit price per sheet.

How to Use a Rotary Press

Printing with a rotary press consists of the following three major steps:

1. Prepress Process

This is the process from composition, design, and editing of the manuscript to be printed to plate making. Before digitalization, printing was done by typing on a transcription machine or creating plates from scanned pictures and photos.

2. Pressing Process

This is the process of printing using the plates created in the pre-press process. Printing is started after preparations such as setting the roll paper, mounting the plate, and adjustment of the ink have been made. At the beginning of printing, printing is done slowly while checking for any abnormalities such as misprinting or density, etc. After that, printing is done at a high speed by increasing the rotation speed.

3. Post-press Process

This is the process of post-processing the printed paper. Cutting is performed according to the size of the final printed product. Depending on the application, folding such as two-fold or four-fold, laminating, foil stamping, or other processing may be applied.