What Is an Ultrasonic Thickness Gauge?

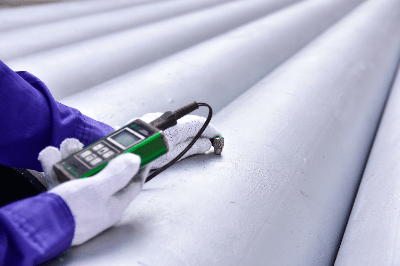

An ultrasonic thickness gauge is a device that employs ultrasonic waves to measure the thickness of an object.

It determines the thickness by measuring the time ultrasonic waves take to traverse the object. This non-destructive method is ideal for product and material quality control. The gauges are highly accurate, capable of detecting minute thickness variations and measuring the thickness of thin materials efficiently.

The operation typically involves pressing the device against the object’s surface and activating the measurement button. Many models boast digital displays and automated measurement functions. Their portability makes them suitable for on-site usage, and their compact design allows for measurements at various locations.

Uses of Ultrasonic Thickness Gauges

Ultrasonic thickness gauges find applications in various scenarios where thickness measurement is essential.

1. Manufacturing Industry

In the manufacturing sector, these gauges are crucial for measuring the thickness of materials such as steel plates and aluminum plates. They are instrumental in ensuring precision in products like automotive body panels and aircraft frames.

2. Construction Industry

In the construction field, these gauges are employed to measure the thickness of concrete in structures and floors, aiding in strength assessment and uniformity checks. They are also invaluable for detecting corrosion in metals, especially in areas like underground piping or building interiors, as they measure thickness reduction non-destructively.

Principle of Ultrasonic Thickness Gauges

Ultrasonic thickness gauges operate on the principle of measuring an object’s thickness using the travel time of ultrasonic waves. The gauge comprises an ultrasonic generator, usually made of piezoelectric or magnetic elements, transforming electrical energy into ultrasonic waves.

These waves are emitted towards the object, where they are reflected and scattered by the internal structure and interfaces. The reflected waves are then captured by a receiver, transformed back into electrical signals, and their travel time is measured.

The calculation unit computes this travel time. With pre-set ultrasonic wave velocity data for the specific material, it calculates the object’s thickness. Accurate velocity data is crucial, as ultrasonic wave speed varies with the material’s composition and density.

Types of Ultrasonic Thickness Gauges

Different types of ultrasonic thickness gauges are designed for specific applications:

1. Single-Element Ultrasonic Thickness Gauge

This gauge utilizes a single transmitter/receiver element, making it suitable for simple thickness measurements in thinner materials.

2. Dual-Element Ultrasonic Thickness Gauge

With separate transmitter and receiver elements, this gauge offers enhanced signal accuracy and sensitivity, applicable to various uses.

3. Dual Element Ultrasonic Thickness Gauge

This type has both transmitter and receiver elements in the same sensor head, ensuring more accurate measurements, particularly under high-temperature conditions and on uneven surfaces.

4. Multi-Element Ultrasonic Thickness Gauge

This gauge features multiple transmitting and receiving elements, allowing for thickness measurements on complex surfaces and shapes.

How to Select an Ultrasonic Thickness Gauge

Consider the following aspects when choosing an ultrasonic thickness gauge:

1. Object to Be Measured

Reflect on the material type and surface condition of the object. Specific materials and shapes might necessitate specialized gauges.

2. Thickness and Accuracy Requirements

Evaluate the range of thickness to be measured and the precision needed. Gauges vary in their capacity to measure ultra-thin or thick materials.

3. Operability

Usability is crucial. Consider features like user-friendly interfaces, simple navigation, and data recording functions.