What Is a Vacuum Pad?

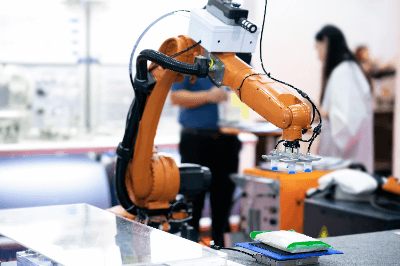

A vacuum pad is a component in a conveying system that absorbs and conveys an object to be conveyed (hereinafter referred to as a “workpiece”).

The vacuum pad is connected to a vacuum generator. With the suction surface of the vacuum pad in contact with the workpiece, the vacuum generator creates a lower pressure (vacuum) in the space between the pad and the workpiece than the ambient air pressure. This causes the vacuum pad to pick up the workpiece for transport. Vacuum pads are used in a variety of fields to improve production efficiency because they require only a vacuum pad and a vacuum generator.

Uses of Vacuum Pads

Vacuum pads are used in various fields because they are available in the configuration of a vacuum pad and a vacuum generator.

For example, they are used to convey relatively heavy metals such as car body pressed steel plates and hot stamping forged steel plates, plate glass, film, plastic, and other plate-like objects, as well as objects with surface roughness such as cardboard boxes and wood.

It can also be used to convey foods such as confectionery and electronic components, such as silicon wafers and cells.

Principle of Vacuum Pads

Vacuum pads are suctioned by creating a vacuum in the space between the pad and the workpiece using a connected vacuum generator. In other words, the principle of the vacuum pad is that suction occurs when the pressure in the space between the pad and the workpiece is lower than the ambient air pressure (usually atmospheric pressure). The suction force of the vacuum pad is directly proportional to the pressure difference between the atmospheric pressure and the pressure inside the pad.

When the vacuum level of the pad, which is controlled by the vacuum generator, is lowered, suction stops when the pad can no longer support the weight of the workpiece. The pad and the workpiece are separated.

There are three types of vacuum generators: ejectors that use the Venturi effect, vacuum pumps that use motor rotation to rotate vanes and suction gas, and vacuum blowers that use impeller rotation to suction surrounding gas.

Types of Vacuum Pads

Vacuum pads are manufactured in various sizes, materials, and shapes in consideration of the operating environment, holding power, and durability to touch various shapes and types of workpieces.

1. Shape

Vacuum pads come in three main shapes: flat, oval, and bellows. The flat type is used for workpieces with flat surfaces.

The ellipsoidal type is used for long, narrow workpieces and is suitable for small areas, such as pipes. The oval shape is flat and has a small volume inside the Vacuum pad, so it can vacuum a workpiece in a short period. The bellows type is used when the height of the workpiece varies due to its bellows shape, and the height needs to be compensated as necessary.

2. Material

Typical materials for vacuum pads are nitrile rubber, silicone rubber, polyurethane, and special high-temperature materials. For example, a silicone rubber vacuum pad is used for food products, which does not affect food products. An oil-resistant, silicone-free vacuum pad is used for automobile bodies.

Vacuum pad material should be matched not only to the material of the workpiece but also to the environment in which it is used. For example, if durability and high-speed transfer are required, a highly durable material that requires less frequent replacement should be used.

How to Select Vacuum Pads

The first step in selecting a vacuum pad is to determine the conditions of use. The main operating conditions include the weight of the workpiece, suction posture, vacuum pressure used, acceleration when lifting the workpiece, acceleration when moving the workpiece, and the coefficient of friction between the workpiece and vacuum pad.

Here, we will use the example of lifting and picking up a workpiece vertically and then moving it horizontally.

- First, determine the theoretical holding force of the vacuum pad when the workpiece is lifted vertically and picked up. The theoretical holding force of the vacuum pad when picking up a workpiece vertically is calculated by multiplying the weight of the workpiece by the sum of the gravitational acceleration and the acceleration of lifting the workpiece vertically, and then by the safety factor. The safety factor is a coefficient related to actual use and should be about 1.5 for general workpieces, and 2.0 or higher for workpieces with hazardous or permeable characteristics that require a strong suction effect.

- Next, determine the theoretical holding force of the vacuum pad when the workpiece is picked up vertically and then moved horizontally. The theoretical holding force of the vacuum pad when moving the workpiece horizontally is calculated by multiplying the weight of the workpiece by the sum of the acceleration due to gravity and the acceleration when moving the workpiece horizontally divided by the friction coefficient, and then by the safety factor.

- Finally, the theoretical holding force of the vacuum pad to be used in the actual equipment is greater than the holding force during pickup or horizontal movement and is used to select the Vacuum pad. In actual equipment, vacuum pads may be used individually or as a set of multiple pads.

The theoretical suction force of an individual vacuum pad is the difference between the atmospheric pressure and the pressure of the pad divided by the atmospheric pressure, multiplied by the suction area and the force due to atmospheric pressure. When using a single pad, select a vacuum pad whose value is greater than the theoretical holding force. When multiple pads are used, the Vacuum pads should be selected so that the value obtained by multiplying the Vacuum pad force of each pad by the number of pads is greater than the theoretical holding force.

Nitrile rubber is often used as the material for Vacuum pads in general applications, but selection should be made according to the Uses of the application and the material of the workpiece, such as using fluorine rubber in clean environments where conductive nitrile rubber or conductive silicon rubber is used in environments where static electricity is not desired.

Other Information on Vacuum Pads

Life of Vacuum Pads

Vacuum pads are made of rubber, so the suction surface wears out with use. Wear conditions vary depending on the frequency of use and vacuum pressure, but severe wear can cause air leakage, reduced suction power, longer suction time, and other problems.

Vacuum pads are usually treated as consumable items and need to be replaced periodically, considering the wear of the suction surface. Although the replacement time varies depending on the operating environment, if the required suction force cannot be obtained due to air leakage caused by wear, it may lead to a major accident, such as a workpiece falling off, so a replacement time should be set well in advance.

For example, the vacuum pressure drop due to leakage at the vacuum pad is measured, and if the pressure drops below a specified value, the pad should be replaced.