What Is Grease?

Grease is a lubricant made by mixing a base oil with a thickening agent to form a gel.

Grease is a lubricant made by mixing a base oil with a thickening agent to form a gel.

Additives such as antioxidants and load-bearing additives are sometimes added to give grease characteristics.

Uses of Grease

Grease is a lubricant that is applied to a wide range of machinery and equipment in industry. The following are examples of grease applications:

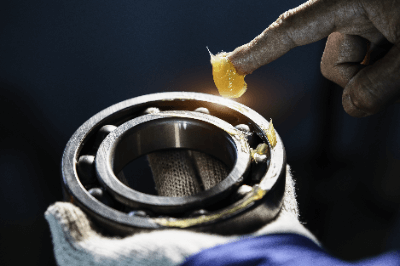

- Preventing friction in bearings and moving parts of equipment and machinery

- Improving adhesion by applying grease to joints

- Aids in heat dissipation of machinery

Lubricant performance, especially in bearings, plays an important role in the automotive and precision equipment industries. Grease that assists heat dissipation in machinery is called heat-dissipating grease, and is used for computer CPUs and heat sinks, etc.

Principle of Grease

Grease is composed of a thickener made of soap molecules that forms a three-dimensional mesh-like structure and incorporates base oil. When stress is applied to the grease, the mesh structure is distorted and the base oil seeps out, thereby performing the role of lubrication. Even if foreign matter comes in contact with the grease, the reticular structure is not significantly disturbed and remains intact, so the function of the grease as a lubricant is not significantly impaired.

Note that the non-Newtonian nature of the fluid must be taken into account when evaluating grease during rotation. Lubricating oil does not produce a wedge effect under low-speed stress and the oil film breaks off. Grease, on the other hand, exhibits constant viscosity even at low speeds and can maintain its film thickness on the shear surface.

Types of Grease

Depending on the type of thickener, grease can also be divided into soap-based grease and non-soap-based grease. In particular, lithium soap-based grease is still used in a wide range of fields.

It is also classified into various types. Typical examples are as follows:

1. Molybdenum Grease

This grease contains molybdenum disulfide. It is characterized by its high extreme pressure property and is often used in heavy-load parts. However, since the viscosity is relatively low, care must be taken to prevent grease runoff.

2. Lithium Grease

This is a soap-based grease in which lithium salt of lithium stearate or hardened fatty acid of castor oil is dispersed in raw material base oil as a thickening agent. Since the development of lithium grease with excellent water resistance and heat resistance in 1938, it has been used as an all-purpose grease in a wide range of fields.

It has excellent water resistance and mechanical stability, both of which are inferior to those of non-soap-based urea grease. However, since some urea greases harden or soften under high temperature or shear, lithium grease is generally used unless the application is unique. It is suitable for use at a wide range of rotational speeds, from low to high.

Since it may adversely affect rubber and resin, use products clearly labeled for rubber or resin products.

3. Chassis Grease

This grease uses calcium soap and other ingredients as a thickening agent. It is widely used in automobiles and is characterized by its high versatility. Although its performance is inferior to that of lithium grease, it is a relatively inexpensive grease.

4. Silicon Grease

This grease is made of silicon oil. Since it does not adversely affect rubber and resin, it is widely used for rubber and resin products.

How to Use Grease

Grease can be used by application, manual lubrication, or automatic lubrication.

1. Application

Application is a method of manually applying grease to the area to be lubricated. Some equipment may specify the application of grease.

2. Manual Lubrication

Manual lubrication is a method for lubricating grease inside linear guides, ball screws, etc. Equipment that requires internal lubrication is equipped with a grease nipple for lubrication, and a grease gun is used to apply grease.

3. Automatic Greasing

Automatic greasing is a system that automatically supplies grease periodically using a grease pump. Grease is supplied to the grease supply position via a rigid tube or the like.

A metering valve is generally incorporated in the piping to maintain a constant grease supply. Grease pumps are generally motorized, and are periodically greased by commands from the control equipment to reduce maintenance man-hours and prevent equipment trouble due to forgotten greasing.

Other Information on Grease

1. Advantages of Grease

Advantages of grease compared to lubricants are as follows:

- Less loss during use, requiring less frequent replacement and lubrication

- Less prone to leakage and easier to store

- Can be used under low speed rotation and shock load conditions

- Even if foreign matter enters the grease, it is retained in the grease and does not damage machinery and equipment.

- Can be used as a lubricant even if a small amount of water is mixed in

2. Disadvantages of Grease

The disadvantages of grease compared to lubricants are as follows:

- Complicated procedures for replacement and cleaning

- Not suitable for use at ultra-high speed rotation because it does not dissipate heat well

- Difficult to remove foreign matter