What Is a Carbon Brush?

Carbon Brushes are conductive sliding parts used in motors and generators.

Carbon Brushes are conductive sliding parts used in motors and generators.

They are used in DC motors and large generators. Since they are sliding parts that wear out, they need to be replaced periodically. If used beyond the marked wear limit line, there is a risk of motor failure.

Uses of Carbon Brushes

Carbon Brushes are used in some motors. They are used in three main applications: rectification, current collection, and grounding.

1. Carbon Brush for Rectification

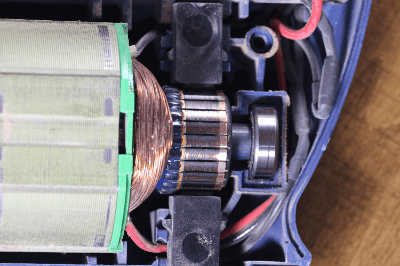

Rectification is an application used for the purpose of reversing the polarity of the winding of a DC motor. The following is an example of the use of a carbon brush for commutation:

- DC motors inside power tools

- Motors for driving windshield wipers and door glass in automobiles

- Running DC motors in streetcars

Carbon Brushes are used inside DC motors attached to battery-powered power tools and in-vehicle equipment.

2. Carbon Brushes for Current Collection

Current collection is an application in which carbon brushes are used for the purpose of passing electricity through a rotating body.

The following is an example of a carbon brush used for current collection:

- Wire-wound induction motors used in overhead cranes, etc.

- For transmitting instrumentation signals to rotating bodies

A carbon brush is used inside a device called a slip ring that transmits electric power and electrical signals to rotating parts. Applications vary, such as internal temperature transmission in mixers.

Most AC motors are cage-type induction motors that do not have carbon brushes, but if a wound induction motor is selected, carbon brushes are used for the secondary winding connection.

3.Carbon Brush for Grounding (Earth Brush)

Grounding brushes are sometimes used to prevent electrical corrosion. Electrical corrosion is a phenomenon in which electricity flows through the rotating shaft of rotating equipment, causing the bearings to corrode due to electrolysis.

This phenomenon is most likely to occur in inverter-driven motors and generators, and is prevented by grounding the rotating shaft with a carbon brush. Carbon brushes that ground the shaft for the purpose of electrolytic corrosion are also called ground brushes or grounding brushes.

Principle of Carbon Brush

Carbon Brush consists of a brush part, a lead wire, and a spring.

1. Brush Part

The brush part is the part that contacts and slides against the rotating body. In most cases, graphite is used as the material. Graphite is used because it is lightweight, rust-resistant, conductive, and slides well.

The size of the brush is selected according to the dimensions of the holder for carbon brush.

Catalog products exist, but in many cases, if you contact the carbon brush manufacturer for the shape and dimensions, they can manufacture a similar product for you.

2. Lead Wire

Lead wire is the wiring part connected to the brush. Most of them are bare copper wires with twisted wire structure. The shape and size of the terminals are selected according to the shape of the terminal block to be connected.

The larger the current value used, the thicker the lead wire and the larger the terminal in many cases.

3. Spring

The spring is the part that applies pressure to push the brush portion against the commutator. It may be omitted if the brush holder is equipped with a spring. Springs are generally mounted around the lead wires.

Other Information on Carbon Brushes

Brushless Motors

Brush motors were the predominant type of motor for DC power supplies. Brush motors use carbon brushes and commutators inside. Therefore, DC motors had the disadvantage of requiring periodic replacement of carbon brushes, which wear out over time.

In recent years, many products have adopted brushless motors for DC power supply motors. Brushless motors are motors that use a dedicated power supply unit to modulate the power supply side. Although they require a dedicated power supply unit, brushless motors are easy to maintain and compact because they do not have brushes.

Brush motors are used when speed control is not required because of their simple structure and low cost. Brushless motors are used when speed control or constant torque operation is desired.