What Is a Curved Conveyor?

Curved Conveyors are devices that move goods where a change of direction is required.

Curved conveyors are mainly used in fields where goods are frequently moved. Curved conveyor contributes to labor saving in conveying goods by efficiently changing the direction and branching the goods.

Curved Conveyor are available with rollers or belts designed specifically for curves.

Applications of Curved Conveyor

Curved Conveyors are installed at intersections where two straight conveyor lines with different conveying directions need to be connected and function to change the direction of parts. When goods are to be moved horizontally within a limited site, it is necessary to change the direction of the goods.

Specifically, they are used to transport various parts and ingredients on production lines for manufacturing automobiles, electronic devices, and foodstuffs through flow operations. They are also useful for transporting and sorting goods in warehouses, transport centers, and other goods transfer lines. The most common places where we see Curved Conveyors in our daily lives are inside conveyor-belt sushi restaurants and in baggage claim areas at airports.

When using a Curved Conveyor, centrifugal force causes items to move toward the outside of the curve. To prevent goods from falling, guide rails machined in the shape of an arc are generally installed together.

Principle of Curved Conveyor

Curved Conveyor can be divided into three main categories, each with a different principle.

1. Curved Roller Conveyor

Curved roller conveyors have a structure that is a reworking of a straight roller conveyor into a circular arc. Roller conveyors use multiple rollers that are arranged in an arc.

The rollers can be straight or tapered rollers. The outside diameter of straight rollers is constant. Tapered rollers have a smaller outside diameter on the inside of the curve and a larger outside diameter on the outside of the curve.

Curved roller conveyors are available with or without a motor to rotate the rollers. In the case of roller conveyors without a motor, the rollers rotate automatically as the material to be conveyed moves.

Due to its structure, a curved roller conveyor can only convey materials that are more than the distance between the rollers. On the other hand, because they are inexpensive and can be made large, curved roller conveyors are applied to heavy or corrugated materials to be conveyed.

2. Curved Belt Conveyor

Curved belt conveyors consist of a continuous belt formed into a conical shape and crossed over tapered pulleys. The belt is a curved belt that is conically formed to match the curvature of the curve. Curved belt conveyors are equipped with a motor as the power source.

When conveying heavy loads, the “head drive system” is mainly used, in which the belt is moved by rotating the downstream pulley with a motor. The conveyor can also be driven by the upstream pulley.

When conveying lightweight materials or materials that require reverse rotation, an intermediate drive system may be used, in which a belt drive pulley is installed between the upstream pulley and downstream pulley, and a motor and inverter are installed.

3. Top Chain Conveyor

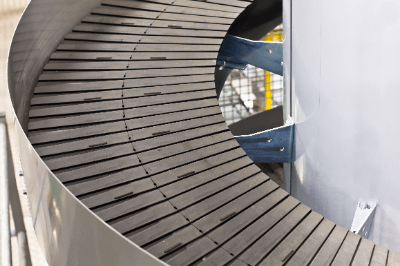

The top chain conveyor consists of a continuous top chain with a top plate, which is crossed over sprockets. A motor is attached as a drive source to move the top chain.

In the case of a top chain conveyor, the overlapping state of the top plate fluctuates at the curve. Curved Conveyors found inside conveyor-belt sushi restaurants and in airport baggage claim areas are top-chain conveyors.

How to Select a Conveyor Curve

When selecting a Curved Conveyor, it is important to consider the type of material to be conveyed and the ease of maintenance.

1. Type of Material to Be Conveyed

Roller conveyors are suitable for conveying materials with a flat underside, but are not suitable for conveying materials with an uneven underside or bag-shaped materials. On the other hand, belt conveyors and top chain conveyors can convey not only materials with a flat underside, but also materials with an uneven underside or bag-shaped materials.

Roller conveyors and top chain conveyors are not suitable for conveying granular materials. In this case, belt conveyors are more suitable.

2. Ease of Maintenance

Belt conveyors require periodic adjustment of belt tension, and top chain conveyors require periodic lubrication of the chain. Therefore, the maintainability of belt conveyors and top chain conveyors is not good. On the other hand, roller conveyors do not require such adjustments and are easy to maintain.