What Is a Urethane Roll?

A Urethane Roll is a metal roll or roller lined with urethane and baked on its surface.

It has excellent soundproofing, sound absorption, sound insulation, oil and chemical resistance, mechanical strength, repulsive elasticity, rolling resistance, heat resistance, heat storage, and abrasion resistance. Depending on the application, urethane color, material, hardness, and length are selected and adjusted.

It has a wide range of uses, including use as cushioning material for chairs, sofas, and mattresses, and is also widely used in general households because of its easy processing. It can also be cleaned at home.

Uses of Urethane Rolls

Urethane rolls are used in a wide range of applications, from automobile interior components to sound deadening and sound absorption. They are also used in the medical field, particularly in nursing care facilities, where they are suitable for everything from beds and examination rooms to rehabilitation floors.

In addition, it can be used as a packing material for packing and transporting products of various categories (fruits, fresh foods, precision equipment, etc.).

As sports mats, they are used in almost all categories of athletic equipment, including indoor, ground, and pool mats, as well as in homes and gyms, such as yoga mats.

Properties of Urethane Rolls

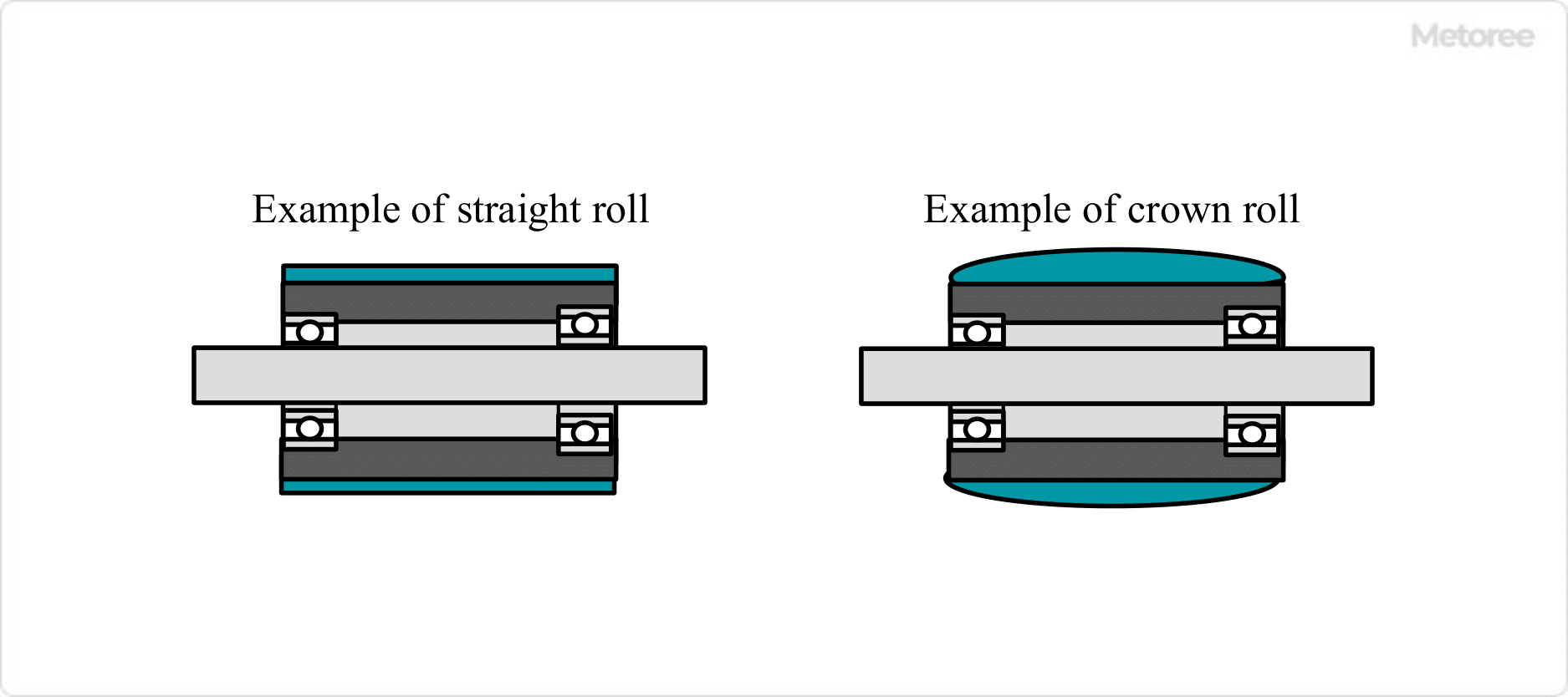

Figure 1. Typical roll structure

The material polyurethane is soft, abrasion-resistant, elastic, and oil-resistant like rubber. Rubber can be broadly classified into two types: natural rubber, made from natural sap, and synthetic rubber, made by molecular polymerization.

Its soft texture makes it suitable for cushioning materials for chairs and mattresses. It is highly versatile in processing, and can be processed into various shapes ranging in thickness from a few millimeters to cubes of several meters. Therefore, it can be widely used as a packaging material for a wide range of genres.

It is also available in a wide range of color variations. The material has soundproofing, sound absorption, and sound insulation properties, as well as high elasticity, making it suitable as a cushioning material. It has excellent elasticity and is difficult to tear even when stretched.

By changing the material, you can choose from a variety of features such as chemical resistance, solvent resistance, low temperature resistance, water resistance, alkali resistance, oil resistance, low and high temperature resistance, load resistance, permanent strain resistance, sulfuric acid resistance, solvent resistance, hydrochloric acid resistance, heat resistance, and tear resistance.

The rolls themselves are also available in a variety of shapes, including regular and crown rolls.

Other Information on Urethane Rolls

1. Urethane Roll Material

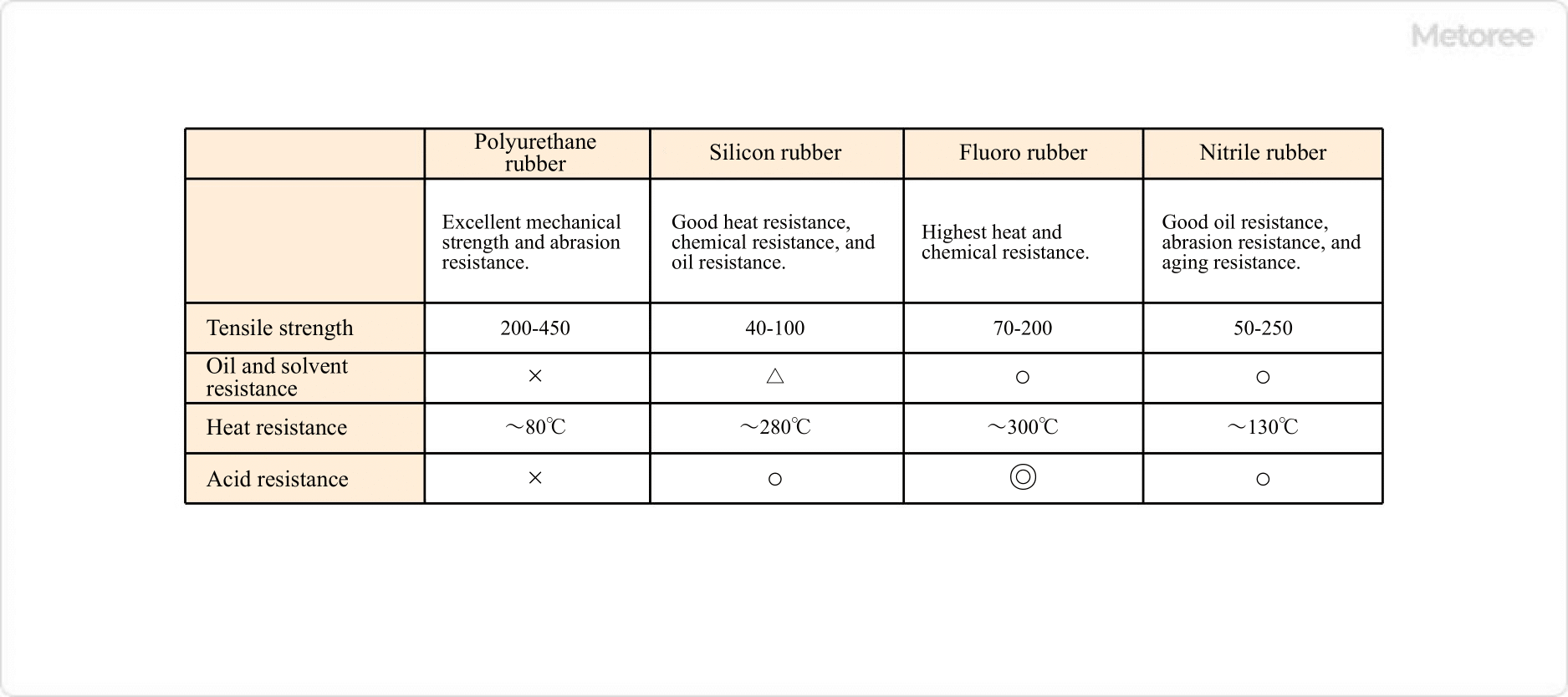

Figure 2. Characteristics of rubber materials

Even if they have the same name of “urethane”, each urethane material has different performance depending on its composition type and hardness. Even hard products have elasticity and shock-absorbing properties compared to other rubber materials.

In particular, it is characterized by excellent mechanical properties. While it has the advantage of high tensile strength and abrasion resistance, its disadvantage is inferior oil resistance performance, heat resistance, and chemical resistance. There are different types of urethane: rigid urethane, soft urethane, ether-based, and ester-based.

1. Hard urethane roller (hardness: 50-95 degrees)

This type of roller is mainly used in industrial applications where strength is required, such as crimping rollers, conveyance rollers, and guide rollers. Urethane has a property of hydrolysis when combined with water.

Hydrolysis is a chemical reaction that occurs when moisture is added to a material due to rain or humidity, causing the previously lumpy material to disintegrate. Hydrolysis occurs after manufacturing and the surface becomes sticky in a few years.

As hardness increases, urethane becomes more hydrophobic (i.e., water does not mix with it easily), making hydrolysis more difficult, and thus urethane is relatively resistant to hydrolysis. Furthermore, even with the same hardness, hydrolysis is more likely to occur with ester-based materials, while it is less likely to occur with ether-based materials.

2. Soft urethane roller (hardness: approx. 20 to 30 degrees)

Soft urethane rollers are used for letterpress printing and printmaking. Generally, ester type rollers are used. Therefore, hydrolysis is more likely to occur.

3. Ether-based roller

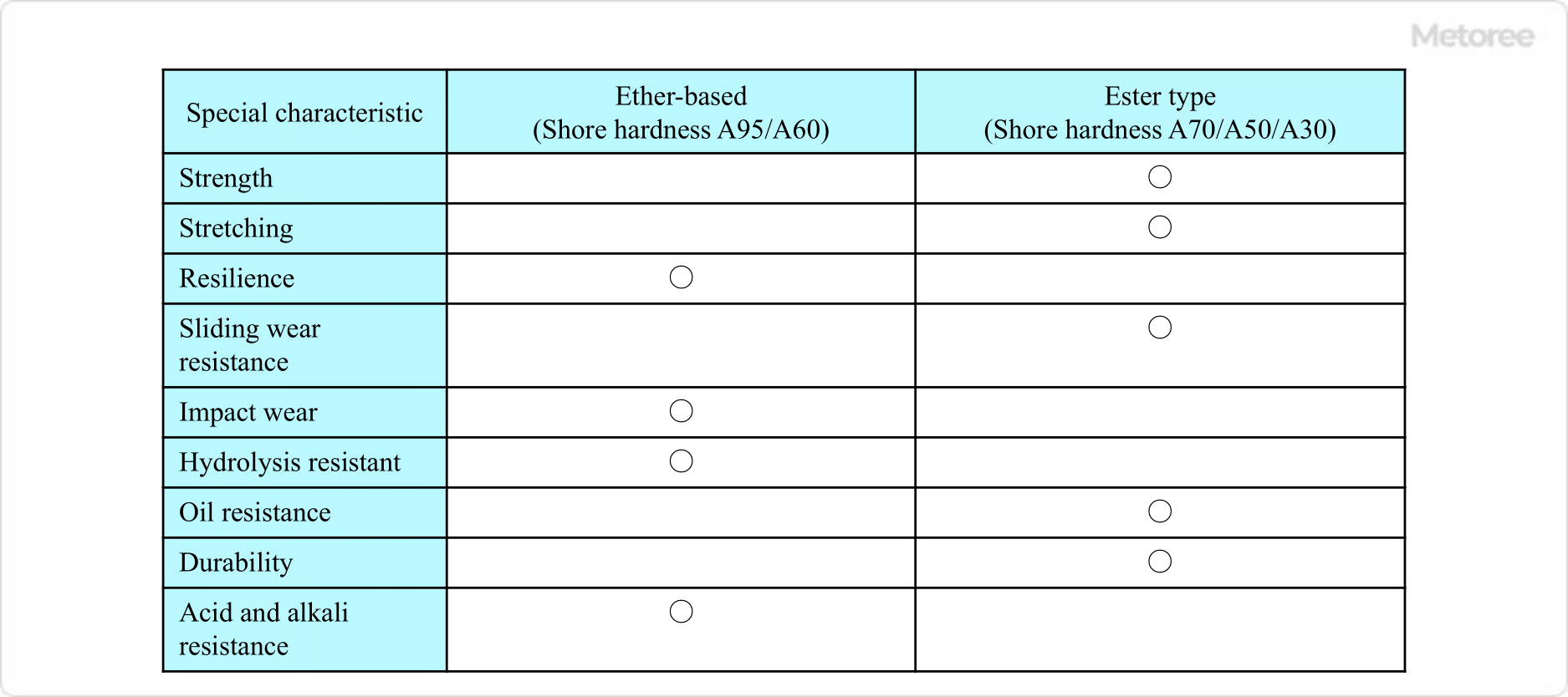

Figure 3. Characteristics of ether and ester systems

Urethane rubber is produced by combining ether-based polyols with urethane. The advantage of this type is that it is relatively resistant to hydrolysis, which is a weak point of urethane rubber. Soft materials as well as hard materials are available, ranging from 20 to 30 degrees Celsius for soft materials and 70 to 90 degrees Celsius for hard materials. However, mechanical strength and abrasion resistance are slightly lower than those of ester-based materials.

4. Ester type

This urethane material has ester bonds in its composition. It has higher mechanical strength, tensile strength, tear resistance, and oil resistance than ester-based materials. As mentioned above, its disadvantage is that it is more prone to hydrolysis than ether-based materials.