What Is a Gripper?

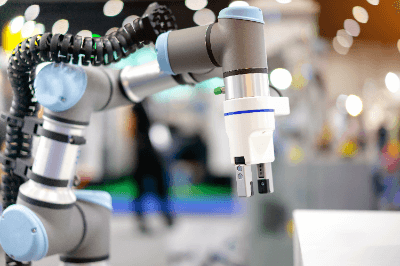

A gripper is a mechanism that grasps (grabs and holds) an object.

The shape of a gripper varies depending on the application, but the most commonly used gripper is a two-finger parallel gripper in which two parallel fingers move in a linear motion to clamp an object. This gripper is used as a device (end-effector) that functions at the end of a robot arm or linear motion mechanism.

By utilizing a gripper, it is possible to grasp, transport, and place objects of various shapes, thereby automating and increasing the efficiency of tasks that were previously performed manually.

Uses of Grippers

Various types of grippers exist in terms of the number of fingers, shape, and type of power source, but this section describes the most common two-finger parallel gripper.

There are two main types of grippers commonly used on product production lines: those with two fingers that open and close pneumatically and those with two fingers that open and close electrically. Variations in gripping force, size, and finger shape are also provided for each product.

When used in a linear motion mechanism such as a cylinder or at the end of a robot arm, the gripper is selected according to the specifications of the moving equipment to be fixed, such as matching the power source and setting the weight of the gripper to less than the payload capacity.

Gripper specifications also vary depending on the shape of the object to be gripped, and when gripping curved surfaces or fragile objects, flexible materials are used on the finger surfaces.

Principles of Grippers

Grippers can be broadly classified according to the power source: pneumatic grippers and electric grippers.

Pneumatic grippers are divided into two closed spaces inside, and when high-pressure air flows into one space, the gripper closes, and when the other space is pressurized, the gripper opens. The high-pressure air piping in the factory is connected to these two spaces, and the opening and closing operation of the gripper is controlled by switching the connection with a solenoid valve or the like.

Pneumatic grippers can be controlled by simply switching open/close valves in the air piping, so they can be operated with simple control using only relays, and their relatively simple mechanism has the advantage of being inexpensive.

Electric grippers incorporate a motor and a feed screw inside, and the opening and closing motion of the gripper is controlled by controlling the direction and speed of rotation of the motor.

Since it is operated by a motor, it is possible to construct complex controls, but a controller such as a PLC is required. Another advantage is that multiple types of objects can be grasped, and the opening and closing widths can be changed at will.

In addition, grippers with three or more fingers may be used when more complex shapes are to be grasped or when human motions are to be learned.