What Is Polyethylene Terephthalate (PET) Sheeting?

Polyethylene terephthalate (PET) sheeting is made from polyethylene terephthalate, a type of polyester. It is produced through a chemical reaction known as polycondensation of ethylene glycol and terephthalic acid, primarily derived from petroleum.

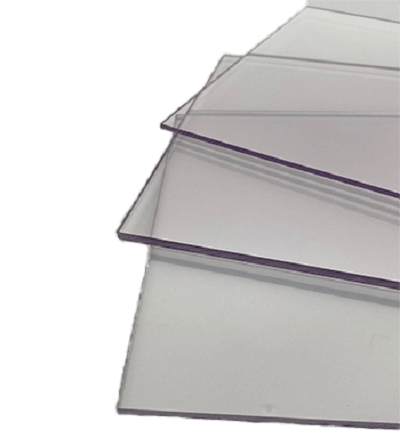

This material is often chosen for food and beverage containers due to its clear, glass-like appearance and low UV (ultraviolet light) transmittance. These properties help prevent the deterioration and alteration of contents due to light exposure.

Uses of Polyethylene Terephthalate (PET) Sheeting

One of the most common uses for PET sheeting is in PET bottles. Other applications include food containers, beverage cups, and clear holders. A-PET (amide-PET), which does not contain stabilizers or plasticizers, is particularly favored for these purposes because of its safety, high transparency, high impact strength, and the fact that it does not emit toxic gases when burned.

Besides, PET sheeting is known for its durability, heat and chemical resistance, flexibility, and formability, making it suitable for industrial parts and covers due to its ability to be molded into complex shapes.

Principle of Polyethylene Terephthalate (PET) Sheeting Production

The production process of polyethylene terephthalate (PET) sheeting typically involves polymer synthesis, molding, cooling, and stretching to form a sheet. Initially, terephthalic acid and ethylene glycol are reacted to produce the PET polymer, which boasts high heat and weather resistance, as well as excellent transparency and strength.

During the molding phase, the polymer is melted and then formed into sheets using either injection molding machines or extrusion molding techniques. This is followed by a quenching process to control molecular alignment and crystallinity, which in turn determines the physical properties and strength of the sheet.

The stretching phase involves heating the cooled sheet while applying tensile force and stretching it in one direction. This process enhances the sheet’s strength and transparency. The manufacturing process is crucial to product quality and characteristics, highlighting the importance of appropriate quality control and manufacturing technology. Additionally, environmental considerations and recycling efforts are significant in the production of PET sheeting.

Types of Polyethylene Terephthalate (PET) Sheeting

There are various types of polyethylene terephthalate (PET) sheeting, each serving different applications.

1. Transparent Polyethylene Terephthalate (PET) Sheeting

This sheeting type is highly transparent, resembling clear glass, yet is lightweight and durable. It’s widely used in beverage and food packaging, display applications, and visual display materials.

2. Dyed Polyethylene Terephthalate (PET) Sheeting

These sheets are suitable for printing and laminating, offering a range of color variations to meet different requirements for color and transparency. This versatility allows for customization to align with product designs and brand images, finding use in packaging, signboards, POP advertising, and more.

3. Heat-Resistant Polyethylene Terephthalate (PET) Sheeting

Heat-resistant PET sheeting can withstand high temperatures, making it suitable for uses that require heat resistance, such as oven trays, heat insulators for electronic devices, and automotive engine compartment parts. It maintains its shape and performance under high temperatures, providing stable functionality.

4. Electrically Insulating Polyethylene Terephthalate (PET) Sheeting

This sheeting has excellent electrical insulation properties, making it ideal for use as insulating material in electrical equipment and electronic components, including electronic circuit boards, solar panels, and electrically insulating sheets, ensuring reliable insulation and safety.

5. Weather-Resistant Polyethylene Terephthalate (PET) Sheeting

Weather-resistant PET sheeting is designed to withstand outdoor conditions, offering long-term durability against ultraviolet rays, moisture, and climate change by inhibiting deterioration and discoloration.