What Is a Deburring Tool?

Deburring tools are designed to remove burrs — unwanted protrusions or residue — created during metal and material processing. Burrs, which can be sharp and hazardous, result from the deformation and tearing of material during cutting or press cutting operations. Removing burrs is essential for safety and quality in manufacturing processes involving sheet metal and other materials.

Uses of Deburring Tools

Deburring tools are essential for:

- Ensuring accuracy in measurements and assembly by removing burrs that could cause errors.

- Preventing product failure and wear by eliminating burrs that could lead to defects or damage during use.

- Reducing the risk of injuries to workers and users from sharp edges left by burrs on metal products.

Principle of Deburring Tools

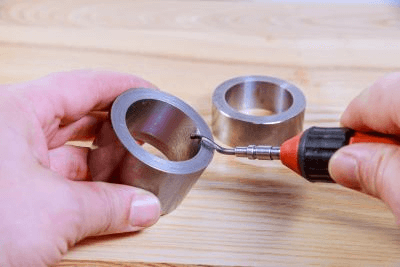

Deburring tools operate by grinding along their edge to remove burrs and smooth out uneven areas. Chamfering, which involves cutting the entire edge of a drilled hole, is another method used to eliminate burrs, offering a smooth finish safe to touch.

Types of Deburring Tools

Various deburring tools include:

- Files, scrapers, and abrasive papers for manual polishing of part edges.

- Grinders, routers, and belt sanders for machine-assisted burr removal by applying the part against a rotating tool.

Selection between manual finishing and machine tools depends on the burr’s condition and the required precision.

Other Information on Deburring Tools

How to Remove Burrs

Burrs typically form at machined part corners, with removal methods varying by part material and the nature of the burr:

- Machining Method: Manual finishing or machine use, such as drilling or milling, to prevent or remove burrs.

- Abrasive Grain Processing Method: Uses abrasive grains in techniques like jet spraying, abrasive flow, or barrel polishing for small part deburring.

- Thermal Processing Method: Employs heat from flames, plasma, or electric resistance to specifically target and remove burrs.

- Chemical Processing Method: Utilizes chemicals to dissolve and remove burrs without affecting the rest of the part.

- Electrochemical Processing Method: Removes burrs through electrolysis by immersing the part in an electrolytic solution and applying an electric current.

Choosing the appropriate deburring method depends on the specific requirements of the application, including the material properties and the desired finish.