What Is a Tube Fitting?

A Tube Fitting is a part used to connect tubes to each other or to devices, parts, equipment, etc. Tube Fittings are sometimes called joints or connectors.

A Tube Fitting is a part used to connect tubes to each other or to devices, parts, equipment, etc. Tube Fittings are sometimes called joints or connectors.

A pipe is generally a cylindrical metal tube, whereas a tube is often a cylindrical or rectangular pipe made of metal, resin, rubber, or glass.

In addition, fittings indicate parts used to connect pipes together. Tube Fitting is available in various shapes (elbow, T-shape, Y-shape), materials (resin, metal, etc.), and sizes.

Uses of Tube Fitting

Tube Fittings are used in all kinds of places, including general industry, research and development, public facilities, and homes. Their purpose is to transfer fluids such as air, gas, water, steam, chemicals, and oil.

Tube Fittings are used not only for connecting tubes, but also for branching (merging) tubes, connecting tubes of different sizes (outer diameters), or connecting tubes to equipment, etc.

Tube Fittings with excellent resistance to high and low temperatures and corrosion, vacuum resistance, and high pressure resistance are also available.

It is important to select a Tube Fitting with the appropriate specifications for the application, taking into consideration the type and pressure of the fluid in the tube. If the specifications do not match, the fluid may leak or the tube may come off.

Principle of Tube Fitting

There are several ways to connect Tube Fittings to a tube, and Tube Retention and Sealability are important.

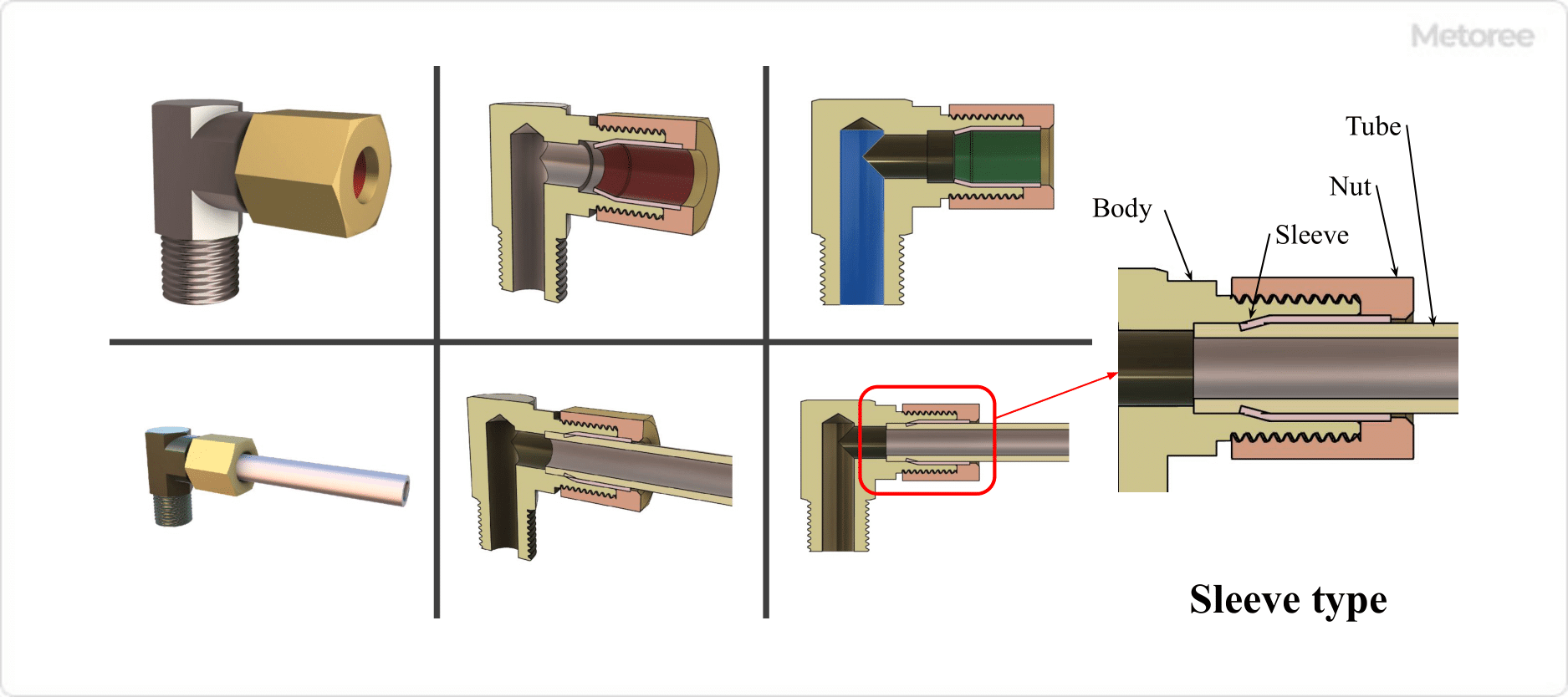

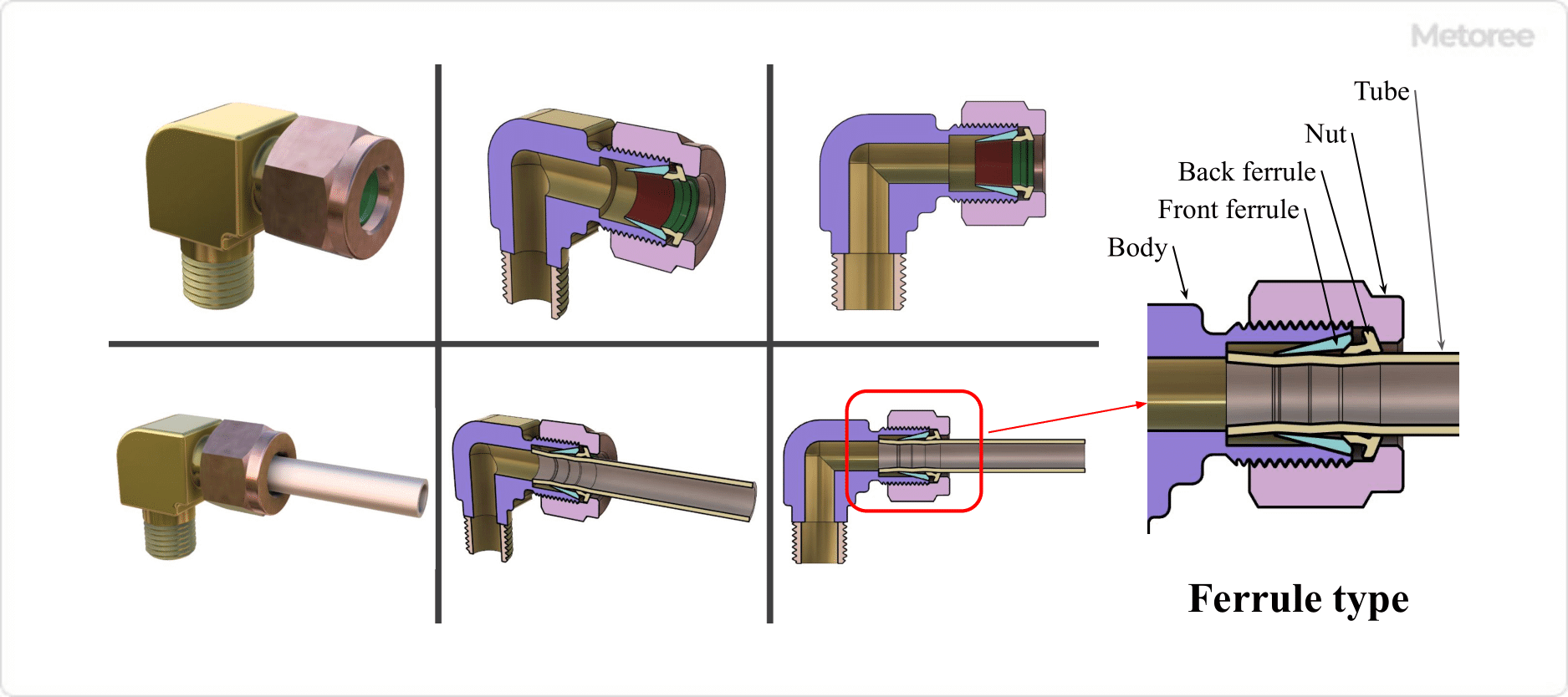

The following two methods are typical methods of holding and securing tubing:

1. Mechanical Fixation

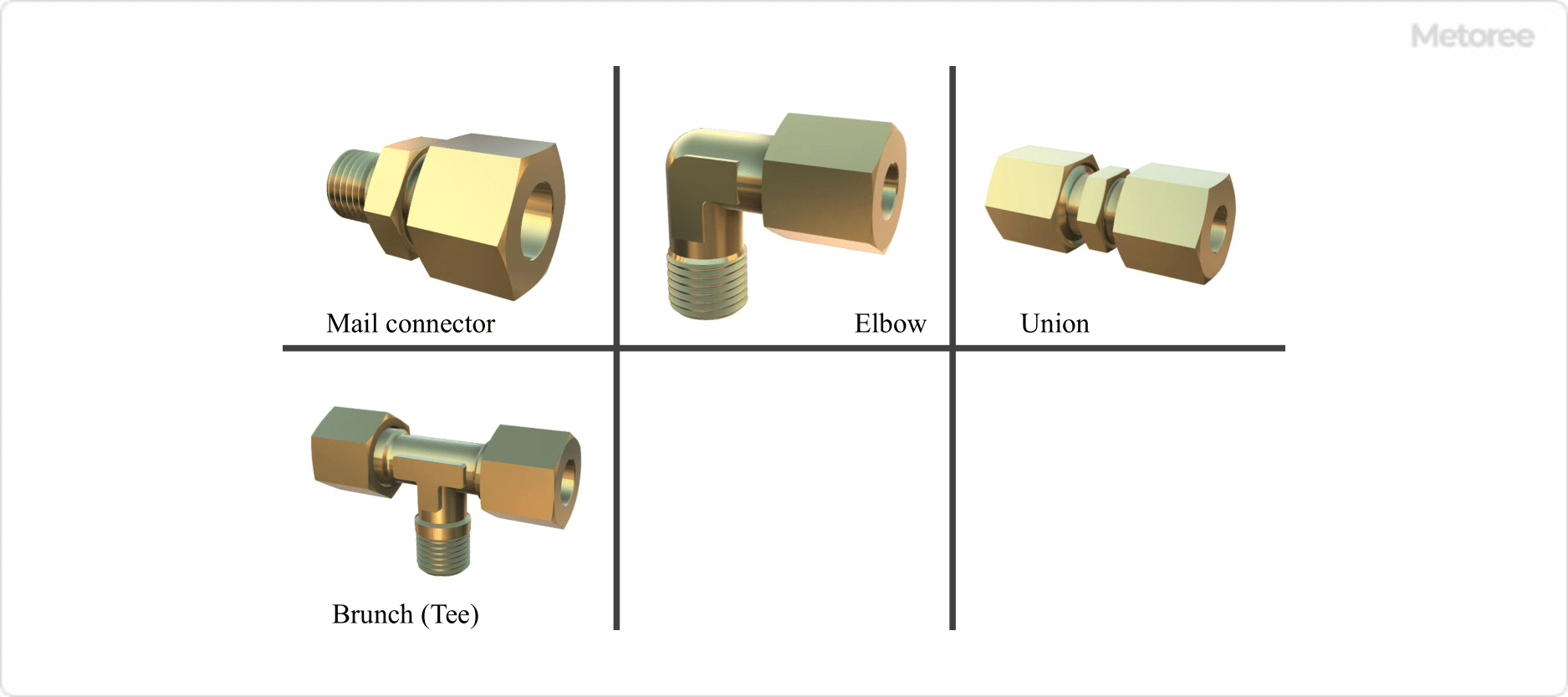

Figure 1. Wedge fitting (1)

The mechanical fastening method is called a wedge fitting (tightening joint). A ring-shaped part called a ferrule or sleeve is fitted into the outside of the tube. Tightening the nut on the tube fitting deforms the sleeve or pushes the ferrule into the tube fitting. As a result, the sleeve or ferrule adheres to the tube to ensure sealing.

Figure 2. Wedge fitting (2)

Wedge fittings are mainly used for metallic tubes such as copper and steel tubes. However, when used for plastic tubing, an insert ring must be inserted to prevent the tube from collapsing.

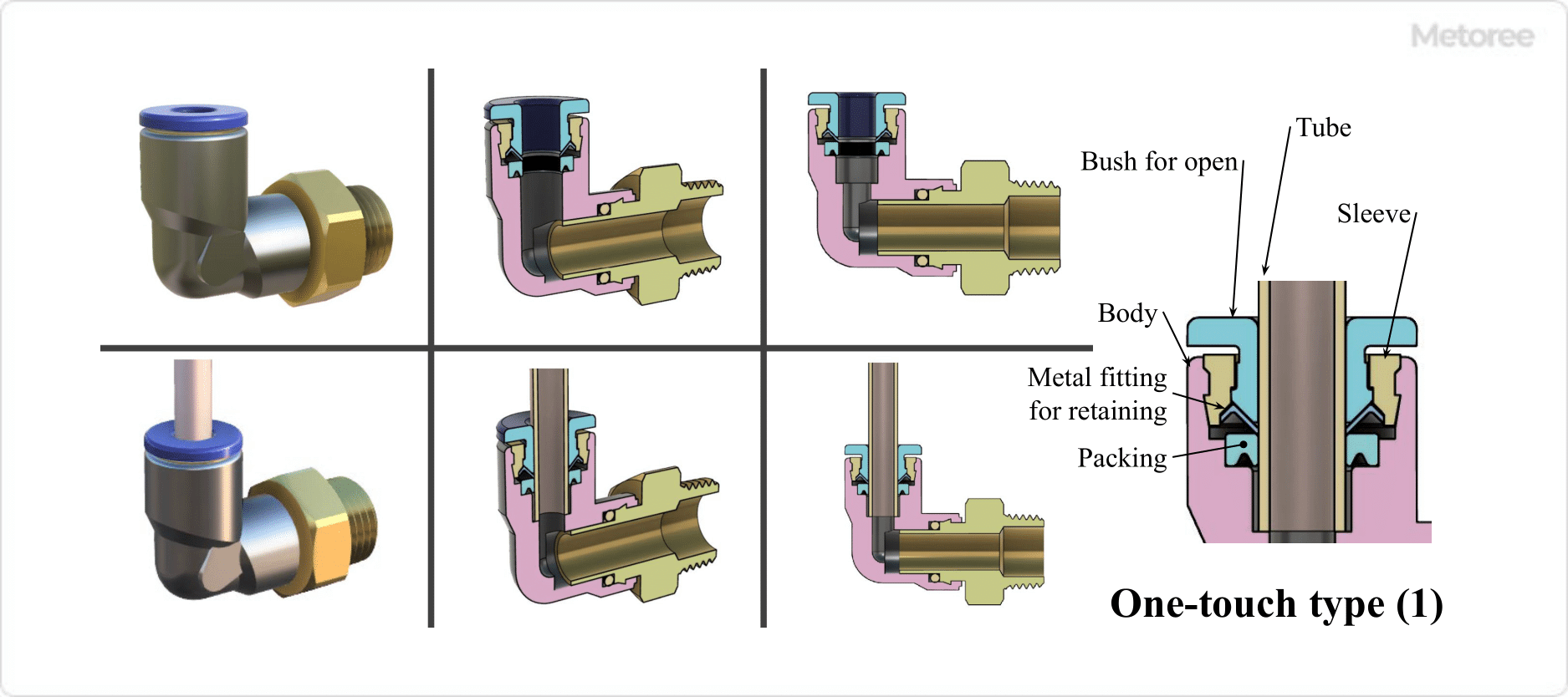

2. One-Touch Type Fixing

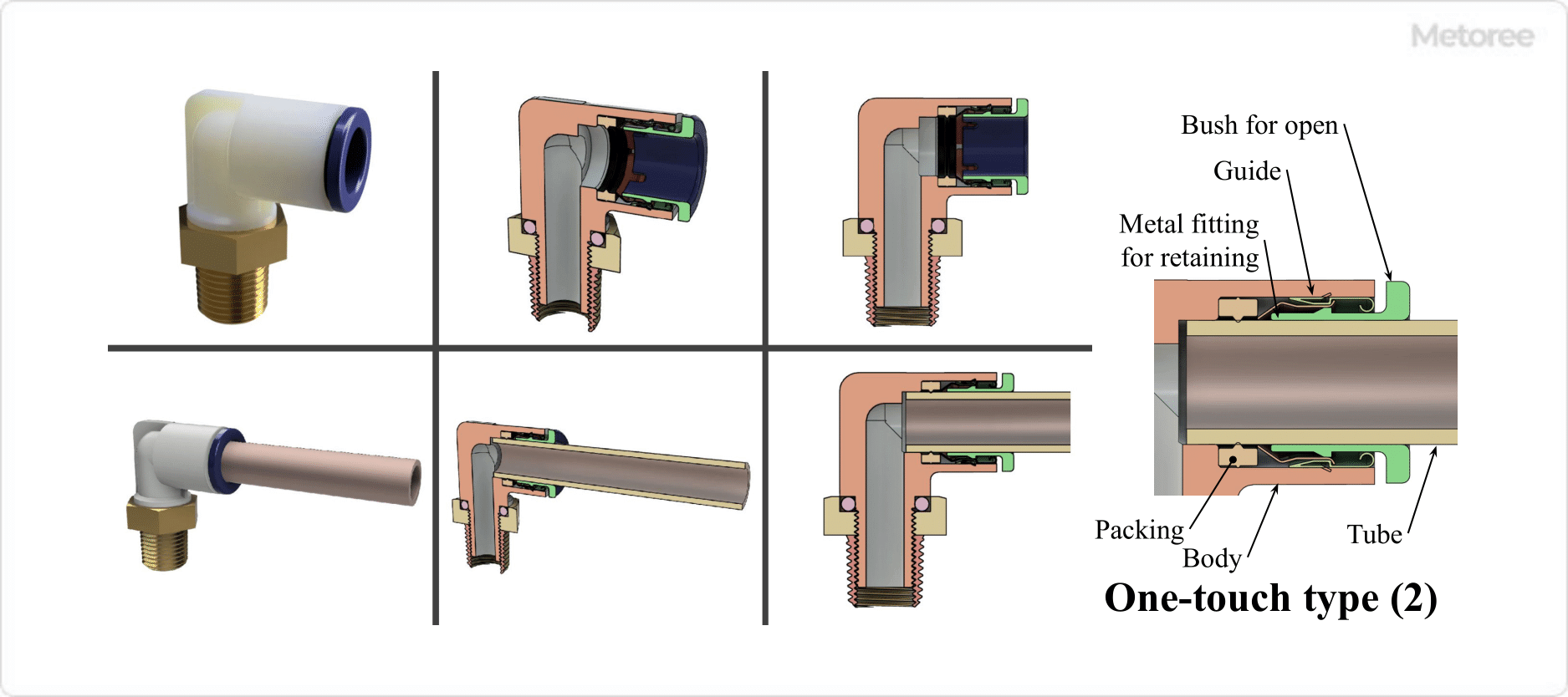

Figure 3. One-touch fitting (1)

One-touch fixtures are a typical example of a fitting for connecting plastic tube fittings and are called one-touch fittings.

One-touch fittings are fittings that can be easily connected and disconnected by simply inserting the Tube Fitting into the fitting.

An O-ring and a metal fitting to prevent disconnection are built into the inside of the fitting, and a packing or O-ring seals the space between the Tube Fitting and the fitting.

Figure 4. One-touch fitting (2)

The tube is secured in place by the fitting, and when removing it, the release bushing in the slot is pushed in to release the lock.

Although Tube Fittings are easy to use, there is a possibility of leakage or damage when using high-pressure fluid or when using Tube Fitting under heavy load.

Types of Tube Fitting

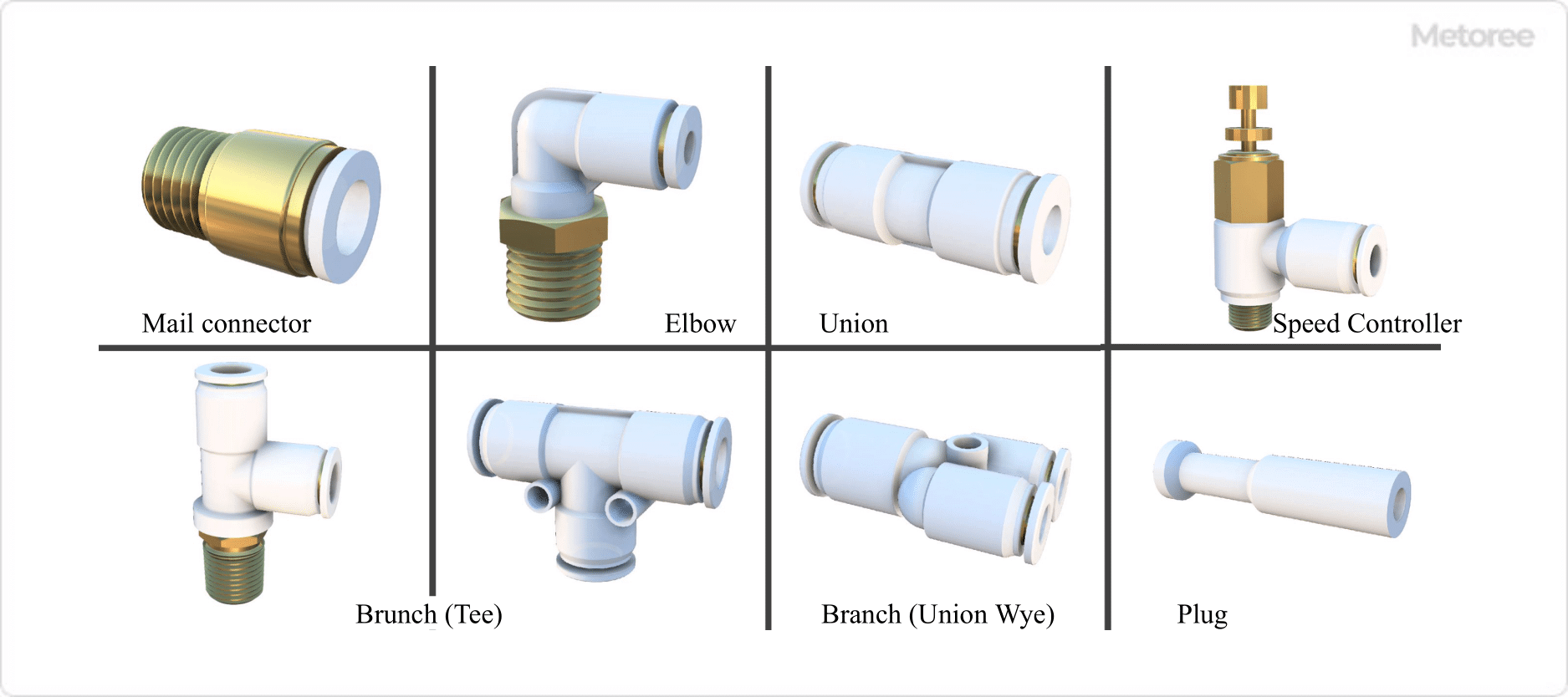

Figure 5. Types of tube fitting (1)

1. Male Connector

This type of fitting has a screw on one side and a Tube Fitting on the other side. Tubes can be easily connected and disconnected with a single touch. The tube can be disconnected by pushing in the part called the release bush.

2. Elbow

An elbow is a Tube Fitting that bends the Tube Fitting at a right angle. Some fittings have a swivel mechanism that allows the tube to be freely oriented.

3. Union

This is a Tube Fitting for connecting two tubes. They are used when extending tubes or connecting tubes of different sizes.

Figure 6. Types of tube fitting (2)

4. Branch

A branch is a fitting used to split a Tube Fitting in two directions from one end.

5. Reducer

A reducer is inserted between a Tube Fitting and a tube to allow connection of smaller sized tubes.

6. Speed Controller

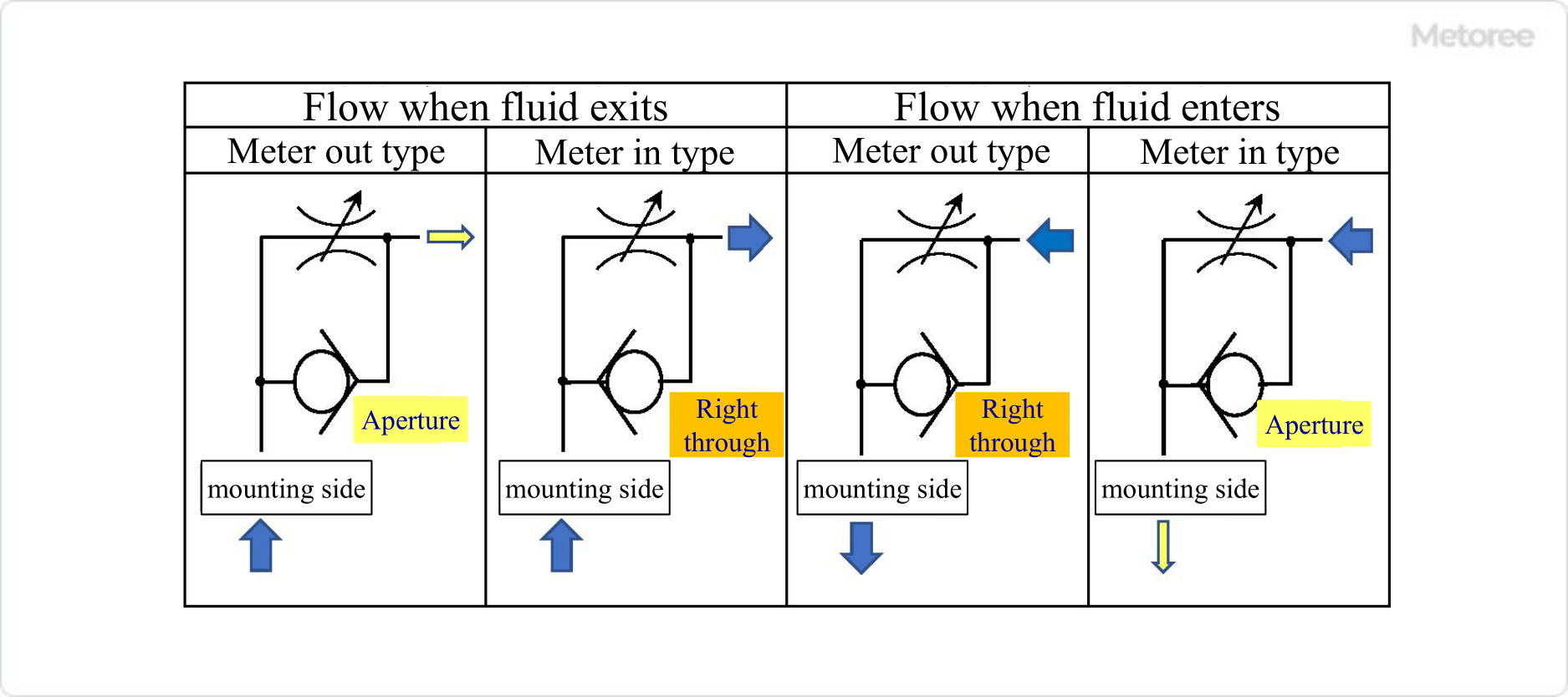

Figure 7. Speed controller flow

This is a fitting that can adjust the flow rate. There are two types: one that can control the flow rate on the discharge side (meter-out type) and one that can control the flow rate on the suction side (meter-in type).

7. Plug

A plug is inserted into a Tube Fitting to cover the unused connection port of the Tube Fitting.

Other Information on Tube Fitting

1. How to Use Tube Fitting

One-Touch Fittings are convenient for use with plastic Tube Fitting in pneumatic piping. When many pneumatic devices such as air cylinders and actuators are used, a solenoid valve box is provided to open and close the air to each device with a solenoid valve with manifold type Tube Fitting.

Leak checks are necessary because leaks in the fittings can prevent the pneumatic equipment from operating properly or cause loss of compressor energy. Leak checks are performed by applying a thin soapy solution to the joint and checking for leaks by the formation of bubbles.

If there is a leak at the border of the tube, the rubber packing or locking mechanism may have deteriorated. If there is a leak at the threaded portion, the Teflon seal may not be wound properly, and the seal needs to be wound and screwed in again.