What Is a Shaking Machine?

Figure1. Typical Shaking Machine

A shaking machine is a machine that shakes and agitates a sample in a container, such as a test tube, flask, or aliquot funnel.

It is also called a shaker. Shakers are often used for time-consuming sample separation, elution, dissolution, and cultivation of aerobic microorganisms.

There are various types of shakers, such as reciprocating, swiveling, and figure-8 shakers, as well as horizontal and vertical shaking directions, depending on the model. Some models are equipped with heating and cooling functions, and can also be used for shaking culture.

There are also sieve shakers that can be used to sieve powders as well as liquids.

Uses of Shakers

Shakers are generally used in the life sciences and chemistry for experiments that require long periods of constant shaking. The main applications in the testing field include various dissolution tests, dissolution of samples, and cultivation of aerobic microorganisms.

In particular, elution tests for soil environmental require the elution of heavy metals in soil by a shaker under specific conditions. In the culture of aerobic microorganisms, the conditions vary depending on the microorganism. It is necessary to calculate the shaking width and shaking speed of the Shaker and to adjust the appropriate oxygen transfer rate.

Other applications include the elution of dioxin and residual pesticides in vegetables with hexane, for example, to test for residual pesticides in food products and to analyze eluted components of industrial waste.

Principle of Shakers

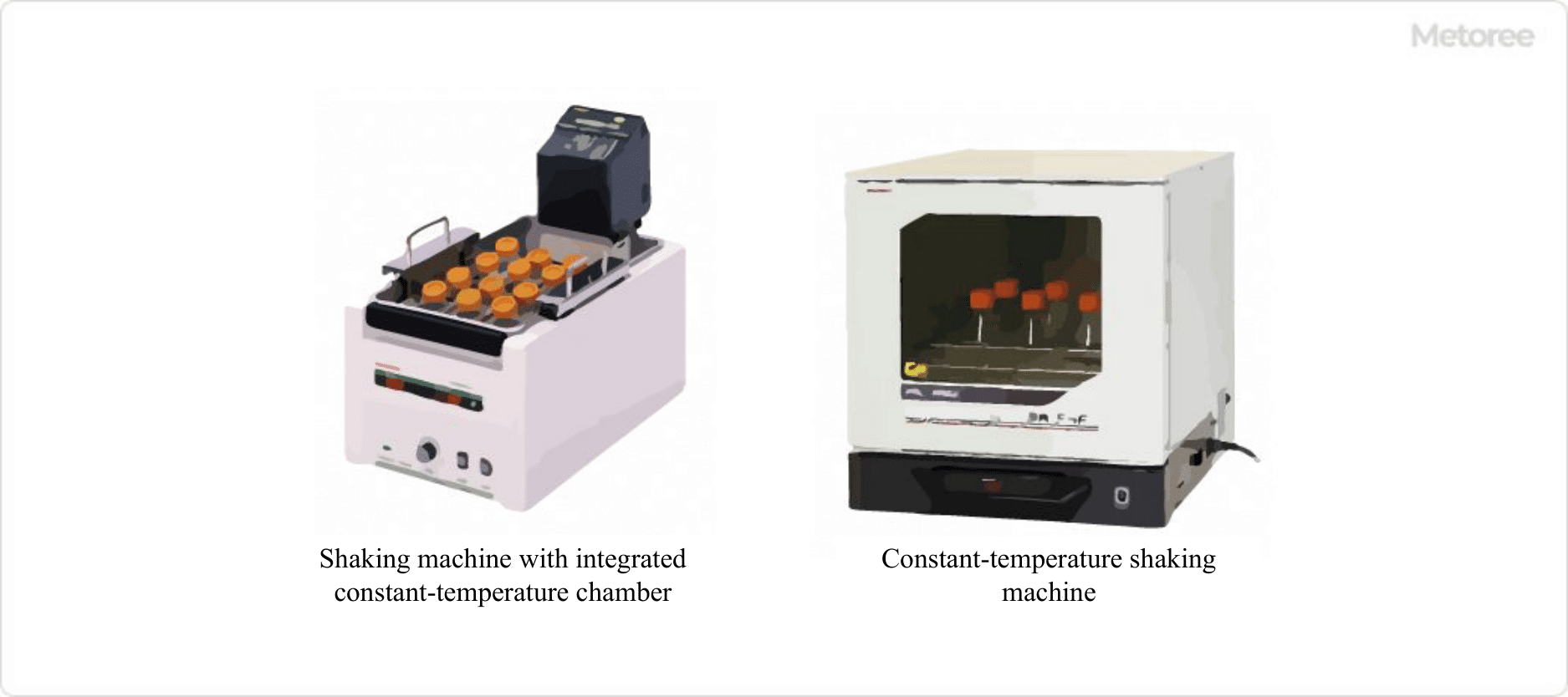

Figure 2. Temperature-controlled shaker

The shaker has a power unit built into the base of the shaking table. The power unit transmits power from the motor to the pulleys via a belt, which converts the rotation of the motor into a reciprocating motion of the shaking table.

Models with a temperature control function have a heater or cooling system under the base. In some cases, the thermostatic bath and shaker are integrated.

Depending on the model, the size of the base can be changed according to the use of the shaker. Some models can be optionally reshaped by placing a special plate for each vessel on top of the base to make it easier to use according to the respective vessel.

Powder sieve shakers use electromagnetic magnets to generate vertical vibrations in the oscillator. A spring adjusts the amplitude of the oscillation, and the sieve is shaken vertically.

Types of Shakers

Figure 3. Various shaking machines

Shakers come in a variety of sizes: small, medium, and large. The choice should be made according to the application and the size and shape of the container. For example, a large shaker should be used for elution tests in soil analysis.

For an in vitro test with a small amount of sample, a small shaker should be selected. In particular, a small shaker should be used when the sample is placed in an incubator for microorganism or cell culture applications. This type of shaker is designed to handle ambient temperatures from about 0 to 50°C and ambient humidity up to about 95% RH.

Most small tabletop shakers fit in the size range of approximately 200 to 300 mm (width) x 180 to 250 mm (depth) x 100 to 170 mm (height). The upper limit of allowable load weight is about 2 kg for most models. Swing types include reciprocating, swiveling, seesaw, horizontal eccentric, figure-8, and other types, with horizontal and vertical directions. Some models incorporate multiple shaking methods that can be switched manually.

Shaking speed can be changed within a range of approximately 20 to 200 rpm. The step- or non-step type depends on the product, and many models have a built-in timer.