What is a Thermal Analyzer?

A thermal analyzer is a generic term for a device that measures changes in a sample when heat is continuously applied to it. It consists of a mechanism for continuously changing the temperature of a sample and a mechanism for detecting and recording the physical properties to be measured. Different analysis names are given to each of these devices depending on the physical property to be measured.

The analyses performed using thermal analyzers include Differential Thermal Analysis (DTA), which analyzes the temperature difference between a measurement sample and a standard sample, Differential Scanning Calorimetry (DSC), which analyzes the difference in calorific values, and DSC Calorimetry (DSC) to analyze differences in heat content, Thermogravimetry (TG) to measure weight changes, and Thermomechanical Analysis (TMA) to measure changes in length.

Uses of Thermal Analyzers

Thermal analysis using a thermal analyzer is used to measure the thermophysical properties of any material. The structure and state of materials change with temperature changes, and the properties and functions of materials change accordingly. Understanding the behavior of materials in response to changes in temperature is very important for controlling properties and quality, and for understanding exothermic/endothermic behavior during reactions.

In a typical thermal analysis, phenomena such as glass transition, crystallization, melting, and decomposition caused by heating are traced graphically with temperature on the horizontal axis and each parameter (weight change, dimensional change, etc.) on the vertical axis. For example, in TG-DTA analysis, by simultaneously measuring the sample weight change when the sample temperature is changed and the temperature difference between the sample and reference material, it is possible to analyze what kind of change occurs at what temperature in the material.

Studies are also conducted to observe changes in morphology by combining thermal analysis with measurements with an optical camera or optical microscope or to analyze gases using gas chromatography simultaneously.

Principle of Thermal Analyzers

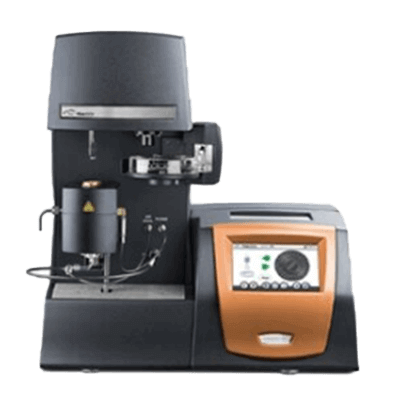

A thermal analysis instrument consists of a detection section, a temperature control section, and a data processing section. The detection section is equipped with a “heater,” “sample mounting section,” and “detector,” and it heats and cools the sample and detects its temperature and physical properties.

The configuration of the detector varies depending on the thermal analysis to be performed. DTA and DSC, which measure temperature, measure the temperature difference between a standard and measured substance. The temperature control section controls the heater temperature according to the program set before the measurement. In the data processing section, signals from the detector are input and recorded, and the obtained measurement data is analyzed.

Analysis Methods of Thermal Analyzers

Various methods are used in thermal analysis depending on the characteristics of the object to be analyzed. There are five analysis methods commonly used in thermal analysis: differential thermal analysis (DTA), differential scanning calorimetry (DSC), thermogravimetry (TG), thermomechanical analysis (TMA), and dynamic viscoelasticity measurement (DMA).

The details of each method are as follows:

1. Differential Thermal Analysis (DTA)

When a sample itself undergoes a transition or undergoes some kind of reaction due to a temperature change, a change in the temperature difference from a reference material occurs, and this change is detected. This allows us to detect reaction phenomena such as melting, glass transition, crystallization, vaporization, and sublimation.

The glass transition is sometimes difficult to detect with DTA because the temperature change is more gradual than other state changes. In the case of unknown samples, it is difficult to understand the reaction phenomena by DTA curves alone fully, so data interpretation methods are often used in combination with thermogravimetry (TG).

2. Differential Scanning Calorimetry (DSC)

A reference material and a sample are similarly subjected to temperature changes, and thermocouples detect their respective temperatures. If there is a temperature difference, the temperatures are heated by a heater so that the temperatures are the same. DSC measures the energy required for this heating. This is why it is called differential scanning calorimetry. In general, it can be measured with higher precision than DTA. It can measure transitions, such as melting, glass transition, and crystallization, as well as specific heat capacity.

3. Thermogravimetric Measurement (TG)

A reference material and a sample are similarly subjected to temperature change, and the weight difference between the reference material and the sample is tracked (a reference material that does not change in weight in the measurement temperature range is used). The sample to be measured undergoes reactions that change its mass, such as sublimation, evaporation, pyrolysis, dehydration, etc., as a result of temperature change. Since not only the weight change but also the sample temperature change can be measured at the same time to detect changes in the state of the sample, analyzers that can simultaneously perform DTA analysis are in widespread use.

4. Thermo-mechanical Analysis (TMA)

A probe is applied to the sample to detect displacement due to temperature change. Measuring the displacement while changing the load applied to the sample is also possible. The main measurement targets are thermal expansion, thermal contraction, glass transition, curing reaction, and examination of thermal history, which are phenomena in which the shape changes due to temperature change. Melting and crystallization can also be detected because shape changes accompany these reactions. Still, care must be taken to maintain constant contact between the probe and the sample to ensure proper detection.

5. Dynamic Viscoelasticity Measurement (DMA)

A cyclic load is applied to the sample, and the strain generated in the sample is detected and output as a function of temperature or time. This instrument is used to examine glass transition, crystallization, and thermal history, which are reactions involving intramolecular motion and structural changes. The initial state of melting can also be measured, but as with TMA, measurement becomes impossible as melting progresses and the shape changes.

Other information on Thermal Analyzers

Applications of Thermal Analyzers

As mentioned above, the combination of an optical microscope and other devices is applied to various research. In the method of real-time observation of changes in morphology and coloration in combination with optical microscopes, it is possible to observe the white cloudiness of samples associated with crystallization and liquid crystal transition, as well as changes in samples near the temperature of state change.

Other analyzers have been developed to analyze gases produced during heat treatment by combining thermal analyzers with devices such as FT-IR (Fourier Transform Infrared Spectrometry) and MS (Mass Spectrometry). By combining information on thermophysical properties obtained by thermal analysis with information on gases, a deeper understanding of the thermal response of materials can be obtained. In combination with other temperature-generating devices, thermal expansion and contraction can be observed in various situations.