What Is a Flexible Cable?

A flexible cable is a wire that is laid flat and coated with insulation.

A flexible cable is a wire that is laid flat and coated with insulation.

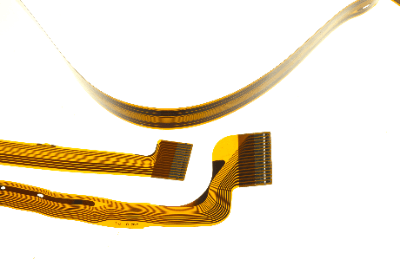

The acronym for flexible cable is FFC. Ordinary wires are made by gathering wires with a circular Cross-section through an insulation layer and coating them so the cross section is round. FFC, on the other hand, is made by lining up flat wires and sandwiching them between resin films that serve as the insulation layer, and is characterized by its flat shape and much thinner thickness compared to ordinary wires.

Uses of Flexible Cables

Flexible cables are widely used as space-saving electric wires because they can be bent. In recent years, flexible cables have been manufactured in response to the trend toward downsizing, weight reduction, and space saving in various types of equipment.

Flexible cables can be used to connect printed circuit boards to circuit boards, as well as to circuit boards and electronic components. Because they are relatively inexpensive and can be bent repeatedly, they are often used where they operate. Examples include home appliances in general, LCD TVs, oil fan heaters, printers and copiers, stereos, VCRs, and telephones.

Flexible cables are available in many variations, including those with many cores, with double-sided tape, halogen-free, and gold-plated.

Principle of Flexible Cables

A flat wire is sandwiched between two pieces of insulating plastic film, with adhesive applied to the joint surfaces, while heat and pressure are applied to the adhesive. By crimping, the thickness of the flexible cable can be made very thin, such as 0.3 mm. Tin-plated copper foil is mainly used for wires, but nickel-plated copper and gold-plated copper are also used.

Polyethylene terephthalate (PET) and polyimide are commonly used as plastic films for insulation. Adhesives such as polyester-based materials are used. Most of the flexible cables have an upper limit of use temperature of about 75°C, which is not very high, but there are flexible flat cables with high heat resistance that have an upper limit of use of about 125°C, depending on the material.

The ends of flexible cables are reinforced with reinforcing plates made of polyester film, etc., and can be connected to connectors. Specific structures include one in which the conductor is exposed at both ends and supported by a reinforcing plate, one in which the conductor is supported by a reinforcing plate with the exposed sides reversed, And the one in which only one end is supported by a reinforcing plate. Some cables have reinforcing plates that are shaped in such a way as to improve the performance of connector insertion.

Hot melt adhesive is used to bond the flexible cable to the reinforcement plate. When used at high temperatures (150°C) while mated to the connector, the adhesive may soften thereby making the connection unstable. There are reports that polyester-based adhesives have been developed to solve this problem.

Flexible Cables and Other Information

Flexible Cable Standards

Most flexible cable products meet UL standards, which are product safety standards established by Underwriters Laboratories Inc. Most flexible cables are UL Listed, a product safety standard established by Underwriters Laboratories Inc.

The markings on the product itself might indicate that the product is UL Listed. FFC products are designed to comply with UL styles, which have specific ratings (temperature and voltage) and flame-retardant ratings. All FFC products have passed the most stringent vertical Flame-retardant test (VW-1).

In addition, some applications may require CSA certification, which is the Canadian safety standard for electrical products such as machine tools, electronic equipment, and medical equipment, and is designed to ensure the safety of human life and property.