What Is a Tab Terminal?

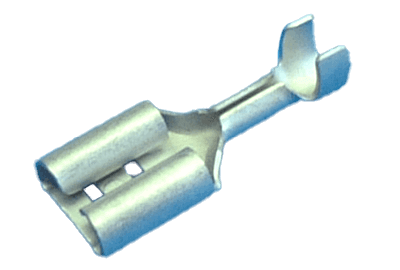

Tab terminals are connectors used for joining wires and harnesses. They consist of a male tab terminal and female receptacle, connecting by fitting the tab into the receptacle. To simplify design processes, terminal standards, including tab terminals, are standardized among manufacturers.

Uses of Tab Terminals

Tab terminals facilitate the connection of cables by inserting the tab into a receptacle. This setup is ideal for situations requiring maintenance, such as cable replacement, since it allows easy disconnection and reconnection. They are commonly used as cost-effective connectors in assembly processes where direct cable routing is challenging.

Principle of Tab Terminals

Tab terminals connect cables by inserting a flat metal tab into a receptacle’s groove. The receptacle’s slightly narrower groove width than the tab’s thickness ensures a secure fit due to metal elasticity. While the standard design provides a robust connection, some models include claws to prevent disconnection. Cables are attached to tab terminals via crimping, requiring careful handling to avoid loosening the connection.

Types of Tab Terminals

Common types include the 110, 187, and 250 series, known as fastons. Manufacturers may introduce proprietary series like the 205, with products available in various packaging forms for board mounting. The wide range of manufacturers underscores the importance of choosing reliable tab terminals for electrical safety.

Other Information on Tab Terminals

1. Precautions for Using Tab Terminals

As tab terminals expose metal, it’s crucial to cover them with an insulator to prevent electric shock and leakage. Only the receptacle side should be insulated, hiding the tab inside the cover upon connection. Proper terminal selection requires special tools and adherence to wire thickness and connector dimensions, guided by industrial standards.

2. Crimping Tool for Tab Terminals

Crimping flat terminals correctly involves using dedicated crimping tools, although some may use pliers for bending and attachment. The crimp’s reliability hinges on the secure fastening of the wire barrel, the terminal part crimped to the wire core. Ensuring the crimp’s strength is neither too weak nor too strong prevents wire pullout or breakage, highlighting the importance of using manufacturer-recommended crimping tools for a reliable connection.