What Is a Programmable Controller?

A programmable controller is a control device with a built-in microprocessor.

Normally, inputs from sensors and switches in equipment are output to motors, displays, and other devices via mechanical relays, timers, and other control mechanisms. In contrast, a programmable controller controls the operation of a device using an internal program, without the need for mechanical relays or other control mechanisms.

Since there are fewer mechanical contacts, the device can be controlled without contact wear and defects between electronic components, cumbersome input/output devices, and wiring between mechanical relays for control. In addition, electrical wiring can be simplified, facilitating downsizing and mass production of devices.

Figure 1 shows a simple example of a control panel that uses mechanical relays, timers, etc. to control lamps.

Uses of Programmable Controllers

Programmable controllers are used in a wide range of fields, including factory automation systems, automobiles, home appliances, and industrial equipment. They are mainly used in industrial and commercial equipment.

Examples of commercial applications include their use in large washers and dryers with sequence control because they are cheaper and more robust than using a PC. Another factor is that they usually do not require cooling systems because there is no graphics board and the microprocessor generates little heat.

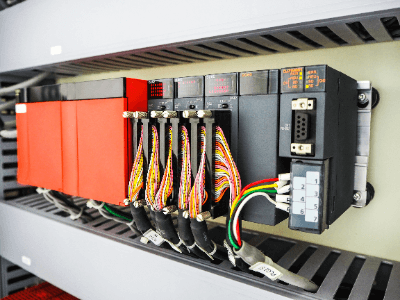

Programmable controllers can be either all-in-one, in which all the electronic components necessary for operation are built in, or modular, in which you select each functional component yourself.

It is important to select the memory, processor, and output/input terminal specifications according to the electronic device to be used.

Principle of Programmable Controller

A programmable controller consists of an input module, an output module, a processor, and memory. The input module is connected to sensors and switches. The processor processes that input data based on the internal program stored in the memory and outputs it to motors, displays, communication devices, etc.

If you wish to change the operation of an electronic device equipment controlled by the programmable controller, you do not need to make any changes to the wiring or other components. You only need to change the program code, which saves time and labor costs.

Programs used in programmable controllers include the ladder method, SFC method, flowchart method, and stepladder method, with the ladder method being the most common. In the ladder method, programs are written on a PC by connecting symbols such as relays, switches, and timers between two parallel lines like a ladder.

This method is easy to learn because the program code can be created using a graphical user interface.

Other Information on Programmable Controllers

1. The Difference Between a Programmable Controller and a Sequencer

If you work in production, you may have heard the term “sequencer.” As it turns out, there is no difference between a programmable controller and a sequencer.

Sequencer refers to the trade name of Mitsubishi Electric’s programmable controller. It was marketed under the name Sequencer as a mechanical device that enabled sequence control and remains in use today as another name for programmable controllers.

2. Connection Between Programmable Controllers and PCs

Generally, a PC is used to store a program in a programmable controller. Each company that sells controllers sells PC software for editing the programs stored on them.

Serial signals have long been used for connection to PCs. In the past, many PCs had serial ports permanently installed, but these days serial ports are rare.

Also, serial signals required matching COM ports or installing special drivers. In recent years, sequence editing is often performed using USB ports, which do not require COM port matching and are familiar to general users.

It is also now possible to edit multiple controllers from an Ethernet port when available.