What Is a Slurry Pump?

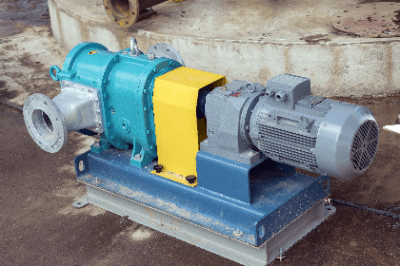

A slurry pump is a pump used to transport slurry, which is a mixture of liquids and solids.

Slurry is very viscous and can wear out or clog the internal parts of the pump. Therefore, they differ from ordinary pumps in that they are specially designed to be highly durable.

There are two types of pumping methods: volumetric, which transports slurry by changing its volume, and centrifugal, which uses centrifugal force to transport slurry.

Applications of Slurry Pumps

Slurry pumps are widely used in various industrial fields. The following are just a few examples of applications for slurry pumps.

1. Ore and Oil Mining Industry

In the mining industry, slurry pumps are used to transport mined materials and sludge. Since transporting particulate matter is often necessary in the ore mining industry, slurry pumps are especially useful.

They are also widely used in the oil drilling industry. During oil drilling, rock needs to be scraped out to reach the depths of oil wells. Slurry pumps are used to pump out the rock debris slurry that forms.

2. Hydroelectric Power Plants

Slurry pumps are also frequently used in hydroelectric power plants. Hydroelectric power plants supply water to spin turbines, and river water contains solid particulates. Slurry pumps are used to discharge water mixed with sediment and other particles after filtering through a screener or other equipment.

3. Construction Industry

Slurry pumps are used to transport crushed stone and sand used at construction sites. They are also used to transport large quantities of earth and sand at dam construction sites.

Principle of Slurry Pump

Slurry pumps require a special design due to the high density of slurry and the variety of solid particles it can contain. The pump consists of an intake to receive the slurry, an impeller to accelerate the slurry inside the pump, and a discharge port to discharge the slurry.

The slurry is drawn in at the intake and accelerated by the rotation of the impeller. The slurry accelerated by the impeller is sent to the discharge port.

Slurry pumps have multiple auxiliary vanes inside the pump to accommodate high-density fluids. This allows for higher pressures to be generated.

Types of Slurry Pumps

Slurry pumps are used in a wide variety of applications. The following are examples of slurry pump types.

1. Single-Stage Type

A single-stage slurry pump is a basic pump for transporting slurry. It consists of a single-stage impeller and is characterized by its simple structure and low cost. However, since it has a single-stage impeller, the corresponding head is often low.

2. Multi-Stage Type

A multi-stage slurry pump has a multi-stage impeller. The multi-stage design allows for a high head and efficient transport of slurry. However, they are typically more expensive than single-stage pumps. Due to the large number of parts, the possibility of failure or blockage is higher than with single-stage pumps.

3. Wear-Resistant Slurry Pump

These slurry pumps have high wear resistance. The materials used in the pump are resistant to abrasion and corrosion. Special alloy steel, rubber, ceramic, and other materials are used for internal parts to improve durability and service life.

How to Select a Slurry Pump

When selecting a slurry pump at the design stage, select the pumping system based on the purpose of transportation, the shape, and hardness of the object, whether it is chemically corrosive or not, and the operating temperature.

It is of utmost importance to understand the nature of the slurry to be transported. The specific gravity and solids concentration of the slurry can provide useful information for selection. Once the nature of the slurry is known, the flow rate should be selected according to the required capacity for pressure.

Ease of maintenance and repair should also be considered. Slurry pumps are often used in harsh environments and may be difficult to maintain and repair. It is ideal to select a pump that can be easily maintained.

Cost is also an important consideration. Slurry pumps are typically more expensive than other pumps due to their characteristics. However, even if the initial cost is high, selecting the right slurry pump may save money in the long run.