What Is a Needle Roller Bearing?

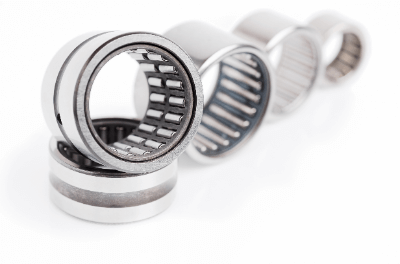

Needle Roller Bearings, also called are bearings in which the rolling element, the roller, is shaped like a needle. Needle rollers are long cylindrical rollers with a small outer diameter.

Needle Roller Bearings, also called are bearings in which the rolling element, the roller, is shaped like a needle. Needle rollers are long cylindrical rollers with a small outer diameter.

Uses of Needle Roller Bearings

Needle Roller Bearings are used in a wide variety of applications in general industrial machinery, automobiles, and many other places and in many different situations. Typical applications include connecting rods for engines and other internal combustion engines. Specialized models are also available.

Needle Roller Bearings, as mentioned above, have a small outer diameter, a large load capacity, and high rigidity compared to other bearings, allowing for a compact design.

Needle Roller Bearings are available in several types, each with different features and applications.

Principle of Needle Roller Bearings

Needle Roller Bearings, like other bearings, are available in radial and thrust versions.

The load applied to the bearing is radial load, which is applied in a radial direction perpendicular to the shaft (rotating shaft) center, and thrust load, which is applied in an axial direction parallel to the shaft (rotating shaft) center. Radial bearings are used when radial loads are applied, while thrust bearings are used when axial loads are applied.

Needle Roller Bearings feature linear contact between the needle rollers and the outer ring or inner ring of the raceway, which provides a larger contact area and lower stress on the contact surface compared to ball bearings.

The small outer diameter of needle rollers allows a large number of needle rollers to be placed in a single bearing, which saves space, increases rigidity, and accommodates high loads. In addition, their low mass and inertia allow them to be used in machines with oscillating motion.

Types of Needle Roller Bearings

There are many types of needle bearings.

Typical types are as follows:

1. Radial Bearings

Needle Roller Bearings with Cage

Needle Roller Bearings with Cages are bearings in which the cage (cage retainer) maintains the spacing between the needle rollers. The cage can be solid, punched, or welded. Needle rollers are available in single row or double row arrangements.

In this type of bearing, the needle rollers, which are the rolling elements, use the mating housing or shaft as the raceway, and there are no outer or inner rings, so the overall dimensions are small and space-saving installation is possible. However, the housing and shaft raceway surfaces with which the needle rollers come into contact must have a high degree of finish machining accuracy, high surface hardness, and sufficient hardening depth to prevent wear.

Caged Needle Roller Bearings are used in engines and transmissions for automobiles and other vehicles.

Shell Type Needle Roller Bearings

Shell Type Needle Roller Bearings consist of a thin steel plate drawn into a shell as an outer ring, a cage and needle rollers. The outer diameter is the smallest among bearings with outer rings, enabling space-saving installation.

The shell allows press-fitting into the embedded part, simplifying installation. Needle rollers are available in a single row arrangement or a double row arrangement. There is also an open-ended type with an open bearing end and a closed-ended type with a cover at one end.

The closed-end type can be used on the shaft end to prevent dust and other contaminants from entering the bearing. Shell Type Needle Roller Bearings are used in industrial machinery in general.

Solid Type Needle Roller Bearings

Solid Type Needle Roller Bearings consist of an outer ring, inner ring, cage and needle rollers machined from alloy steel. Some models have no inner ring and the needle rollers are in direct contact with a shaft or other raceway.

The outer ring is machined from alloy steel and has high rigidity as a bearing and high dimensional accuracy of outer diameter. Needle rollers are available in a single row arrangement or a double row arrangement. Solid Needle Roller Bearings are widely used in printing machinery, machine tools and general machinery.

Solid Type Needle Roller Bearings Separated Type

Solid Type Needle Roller Bearings Separated Type is a type of needle roller bearing in which the outer ring and inner ring can be separated from the needle roller (with cage) in the solid needle roller bearing described above. Each component can be separated and disassembled to simplify assembly.

2. Self-Aligning Needle Roller Bearings

Self-aligning Needle Needle Roller Bearings have an alloy steel outer ring that is machined to have a spherical outer diameter and rotates inside the shell. Like shell bearings, they consist of a shell, outer ring, inner ring, cage and needle rollers.

However, unlike the shell bearing separate type, the shell, outer ring, and needle roller (with cage) cannot be separated.

In the case of the bearing with inner ring, the inner ring and the other parts can be separated as a single unit. This type of needle roller is applicable when the shaft deflection is large or centering is difficult.

3.Clearance Adjustment Needlele Roller Bearings

Clearance adjustment needle roller bearings consist of an alloy steel outer ring with multiple grooves, a cylindrical inner ring, a cage, and needle rollers. As with self-aligning bearings, the outer ring and needle rollers (with cage) cannot be separated.

If an inner ring is provided, it is possible to separate the inner ring and the other parts as a single unit. When the outer ring is pressed in the axial direction (toward the center of the shaft axis), the inner diameter of the outer ring decreases and the clearance of the needle rollers can be adjusted.

Needle Roller Bearings with adjustable clearance are used for high speed and high rotational accuracy applications such as machine tool spindles.

4.Combined Type Needle Roller Bearings

Combined Needle Roller Bearings are bearings that combine the functions of both radial and thrust bearings. It is more compact and space-saving than installing both radial and thrust bearings.

Needle Bearings are used for radial loads, and Ball Bearings, Roller Bearings or Needle Bearings are used for thrust loads. Combined Needle-Bearings are used in machine tools and reduction gears.

5. Thrust Needle Bearing

A thrust needle bearing is a needle bearing used when a thrust load is applied. Like needle bearings with cages, thrust needle bearings are bearings in which the cage (cage retainer) maintains the spacing between the needle rollers. Special outer and inner rings are available and can be used as required.

The cage can be made of punched steel plate, aluminum alloy, or resin. Thrust needle bearings are used in machine tools and pumps.

6. Track Roller

Cam Followers

A cam follower is a bearing that incorporates a Needle Bearing (with cage), a Track Roller (outer ring), and a shaft (stud) on the inner ring side. The shaft protrudes on one side of the bearing only.

The track roller can be cylindrical or spherical in outer diameter. The cylindrical shape has a larger contact area, which is advantageous for high loads, while the spherical shape can tolerate a slight mounting error.

The shaft end is threaded and can be easily attached to the equipment with nuts. Cam followers are used when track rollers rotate and move on a track provided in equipment or facilities.

Roller Followers

A roller follower is a bearing consisting of Needle Bearing (with cage), Track Roller (outer ring) and Inner Ring. It differs from a cam follower in that it has an inner ring instead of a shaft, but is otherwise the same as a cam follower. There is also a model without inner ring.