What Is a Duct?

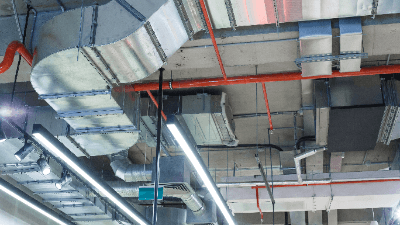

A duct is an air conditioning system and refers to an air passageway. They are used for ventilation, air conditioning, and smoke exhausts in buildings, as well as for large machines to exhaust internal heat and impurities.

There are various types of ducts, and their sizes and materials vary depending on the installation location and intended use.

Use of Ducts

Ducts are used for the ventilation and air conditioning of buildings.

By using a blower or other device to create a flow inside the building and then ventilating it outside through ducts, fresh air, and temperatures can always be maintained inside the building.

There are two types of ducts: square ducts and round ducts. The uses of each are explained below.

1. Square Duct

Square ducts are used in straight and curved sections and are considered to have higher exhaust performance than round ducts. Therefore, they are used in kitchens, where a lot of exhaust air is required.

2. Round Duct

Round ducts are stronger and are used in places where durability is required, such as housing complexes and offices.

Principle of Ducts

First, let us start by explaining the difference between “ducts” and “piping. The biggest difference between “ducts” and “pipes” is that “ducts” allow only airflow, while “pipes” allow not only air but also water, various gases, and other fluids to pass through. Another difference is that “piping” tends to be a large-scale operation, whereas “ducting” is a simple operation.

The following is a list of the four main materials used for ducts.

- Galvanized: the most used material. It is used for air conditioning and exhaust air.

- Stainless steel: stainless steel has excellent corrosion resistance. Used in rust-prone areas such as food factories and air conditioning units.

- Galvanized steel: synthetic plating of aluminum and zinc. It has excellent corrosion and heat resistance and is less expensive than stainless steel. 4.

- PVC-coated steel: resin-coated zinc plating. It is mainly used in pharmaceutical plants because of its superior resistance to alkalis and chemicals.

Care must be taken when installing ducts, especially regarding bends and slopes. Bends should be minimized as much as possible, extreme bends should be avoided. The length should be as short as possible because bends cause turbulence and resistance to airflow. In addition, ducts should be sloped because condensation can cause water to accumulate in the ducts. Ducts also make noise due to vibration, etc., so it is necessary to use reinforcement materials to prevent noise.

Outlet and Inlet of Ducts

There are various shapes of duct outlet/intake ports.

In office buildings and department stores, ceiling-mounted air outlets called “amonestats” are the standard, and they are available in round or square shapes. Amonestats have a cross-sectional structure with multiple overlapping wings, and the air that is blown out radiates, spreading the air throughout the room.

A “garage” is widely used at the intake port for taking in outside air. To prevent rainwater from entering outdoor use, the structure is fitted with drainage and water-return wings. Since they are used outdoors, weather-resistant and durable materials such as stainless steel are used. In addition, measures must be taken to install stainless steel netting to prevent insects and birds from entering.

In addition, various other types of blowing and intake ports are used according to the purpose. This includes the nozzle type to deliver air widely in large spaces such as gymnasiums and the universal type with movable wings attached.

Cautions for Duct Installation

Duct installation also requires attention to the following four points.

1. Loss Resistance of Ducts

Loss resistance in ducts obstructs the internal airflow and increases the air-blowing power, resulting in wasted energy.

The first step is to make the duct length as short as possible. In addition, supply and exhaust ports, branches, and bends create large loss resistance, so these should be minimized as much as possible. Nevertheless, unreasonable duct connections create significant loss resistance. Therefore, it is important to avoid forced connections while minimizing distances and bends and branches as much as possible.

2. Condensation in Ducts

Condensation may occur in ducts in some cases. Condensation in ducts can lead not only to corrosion of the ducts but also to electrical leakage and fire due to water entering a crisis through the ducts. To prevent this, a slope may be provided to drain the water in the ducts to the outside.

3. Vibration and Noise of Ducts

If ducts are installed incorrectly, vibration from blowers and other motors can be transmitted to the ducts, causing vibration and noise, so these measures are necessary.

One of the countermeasures is to install “deflection joints” to prevent equipment vibration from being transmitted to the ducts. In addition, by using “flexible ducts” with a bellows structure at the connection, not only can vibration be suppressed, but they can be used in locations where installation is difficult because they can be flexibly bent. Noise reduction can also be achieved by installing a sound-deadening box. The sound deadening box is filled with rock wool or glass wool inside to provide sound absorption and muffling functions.