- What Is a Photoelectric Sensor?

A Photoelectric Sensor is a sensor that detects light.

A Photoelectric Sensor is a sensor that detects light.

The sensors use the properties of light to detect the surface shape and condition of the object being measured, as well as its constituent materials.

They are suitable for pre-shipment inspection and nondestructive testing equipment because they can detect surface shape and constituent substances without contact.

They are characterized by their ability to measure long distances, short response time, and high resolution. Detection methods include transmissive, retro-reflective, and diffuse-reflective types.

Uses of Photoelectric Sensors

Photoelectric sensors are used in a wide range of applications from consumer products to industrial equipment. Examples of applications are as follows:

- Inspection in production plants for food, consumer products, etc.

- Automatic doors and ticket gates of buildings and condominiums

- Distance measurement sensors for mobile transportation equipment such as trains and automobiles

- Laboratory equipment such as thickness measuring instruments and non-destructive testing equipment

Principle of Photoelectric Sensors

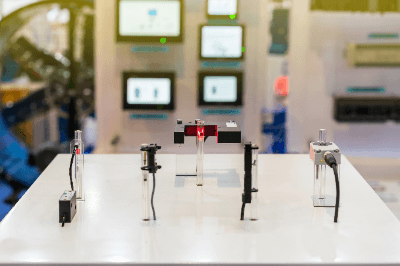

Photoelectric sensors consist of a projector with a built-in light emitting element, a receiver with a built-in light receiving element, an amplifier or other amplifying device, and an output terminal.

They can be classified into transmission, retro-reflection, and diffuse-reflection types according to the measurement method.

1. Transmission Type

In the transmission type, a measurement target is placed between the projector and receiver, and light emitted from the projector is intercepted by the measurement target to detect the target. As long as the object is opaque, measurement is possible regardless of its color or constituent substances.

2. Retro-Reflection Type

In the retro-reflection type, a projector and a receiver are combined into a single unit, and the object to be measured is placed between the projector and the receiver and a reflector. The reflector can be installed in a narrow space, allowing measurement in a limited space.

3. Diffuse-Reflection Type

The diffuse reflection type detects light emitted from the transmitter and receiver by reflecting it back at the object to be measured. It is characterized by its ability to distinguish colors.

Other Information on Photoelectric Sensors

1. Difference Between Photoelectric and Laser Sensors

Photoelectric and Laser Sensors are divided by the type of light source used. Photoelectric sensors generally use LED light sources, while laser sensors use laser light.

Laser light is more directional than LED light, and the diffusion of light emitted from the projector is smaller. Therefore, even small objects can be detected. Also, the light can be projected over long distances without attenuation due to its high energy.

When LED light is emitted from a floodlight, it cannot detect small objects due to diffusion and wrap-around effects. It is also not suitable for detection over long distances because its energy is not high. Also, if neighboring photoelectric sensors are installed nearby, false detection may occur due to diffuse light.

Photoelectric sensors are therefore used when less accuracy is required and are less expensive. Laser sensors are used for applications that require high accuracy, such as long-distance detection and small object detection, and are relatively expensive.

2. How to Use Photoelectric Sensors

Photoelectric sensors are used in many facilities because they are inexpensive and easy to handle, but if used incorrectly, they can cause problems.

One of the most common problems with photoelectric sensors is mutual interference between adjacent sensors. Mutual interference occurs when light emitted from the light emitter of one sensor enters the light receiver of the other sensor.

The LED light source of a photoelectric sensor diffuses the light after irradiation, and the longer the projection distance, the greater the diffusion width.

To prevent mutual interference, it is effective to separate the installation distance, to install the light emitters and receivers alternately, and to install anti-interference filters or light shields. Generally, the recommended installation distance is 1.5 to 2 times the operating distance. If the installation distance needs to be closer, interference prevention filters should be considered. Anti-interference filters are sold by various manufacturers according to the sensors.