What Is a Temperature Controller?

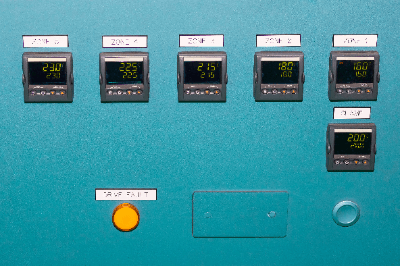

A temperature controller is a device that controls temperature by comparing the measured temperature with the set temperature.

A temperature controller is a device that controls temperature by comparing the measured temperature with the set temperature.

It takes in the temperature detected by sensors such as thermocouples and thermistors, compares it with the set temperature, and outputs an electrical signal. The output signal is then used to control heaters and cooling devices to maintain the set temperature. In the home, temperature controllers are used in water heaters and air conditioners, and in industrial applications, they are often used to keep outdoor storage tanks warm.

Uses of Temperature Controllers

Temperature controllers are used to regulate and control the temperature of liquids and gases.

In industrial applications, they are often used to control process temperatures. Automatic control using temperature controllers minimizes the use of steam and electricity, contributing to energy conservation.

Also, for use in general household products, temperature regulators are used in water temperature controllers for tropical fish, water heaters, and air-cooling equipment such as air conditioners and refrigerators.

Principle of Temperature Controllers

Temperature controllers are mainly used to control heaters and cooling systems by comparing and calculating the measured and set temperatures. For a system whose temperature is to be controlled, the system generally consists of a temperature measurement sensor, temperature controller, and heating/cooling equipment.

The temperature measuring sensor measures the temperature of the object to be controlled. Resistance temperature sensors and thermistors are used. A temperature controller is an electronic device for control. It controls output by feeding back temperature. Air conditioners and heaters are used for heating and cooling equipment. Air conditioners use a compressor to compress refrigerant and can both heat and cool.

Temperature Controller Control Method

There are two types of temperature controller calculation outputs: continuous control and ON-OFF control.

1. Continuous Control

PID control is a control method that calculates input signals using proportional, integral, and derivative (abbreviation of Proportional, Integral, Derivative) elements.

In severe processes where overshoot cannot be tolerated, fine adjustments are made with differential control. Proportional control, integral control, and derivative control are abbreviated as P control, I control, and D control using the initial letters of the alphabet.

- P Control

Control is proportional to the deviation between the input value of the temperature measurement sensor and the temperature setpoint. - I control

I control eliminates the deviation between the input value of the temperature measurement sensor and the temperature setpoint. - D control

Controls used to fine-tune the difference in temperature change due to external factors.

2. ON-OFF Control

ON-OFF control compares the measured temperature with the set temperature and turns the chiller on and off. Compared to continuous control, ON-OFF control is simpler and can be introduced at a lower cost.

Other Information on Temperature Controller

1. Thermostat and Temperature Controller

Thermostats are simple temperature controllers that have been around for a long time. It uses the expansion and contraction of a metal or liquid due to temperature to control temperature by turning contacts or valves on and off. They are often used to regulate the cooling water to radiators in automobiles and other vehicles, and to control the temperature of electric kettles. Thermostats are available in metal and liquid expansion types.

- Metal Type Thermostats

Metal type thermostats use a temperature sensor called a bimetal. This is a plate made of two different metals with different thermal expansion coefficients and uses the expansion and deformation caused by heat as an electrical contact point. - Liquid expansion thermostats

Liquid expansion thermostats use the force of expansion and contraction of a liquid enclosed in a container as an electrical contact point. Liquid expansion thermostats are characterized by their ability to increase electrical capacity. Both types of thermostats do not require a power supply for control.

2. Temperature Controller and Heater

Temperature controllers control temperatures above ambient (room) temperature by issuing control commands to heaters (heating devices). Temperature controllers have a fixed controllable power capacity, so when a large-capacity heating device is used, a separate drive device such as an electromagnetic switch must be provided.

To control temperatures below ambient (room) temperature, a chiller or other cooling device is used. Temperature controllers, heaters, and chillers must have the appropriate specifications and capacities for the intended use. A temperature sensor is also required for temperature control.

3. Indicating Controller and Temperature Controller

A temperature controller is a type of indicating controller. Indicating controllers control not only temperature but also humidity, flow rate, pressure, and many other factors. Both indicating controllers and temperature controllers are only arithmetic devices, and sensors and chillers are required separately.