What Is a Laser Sensor?

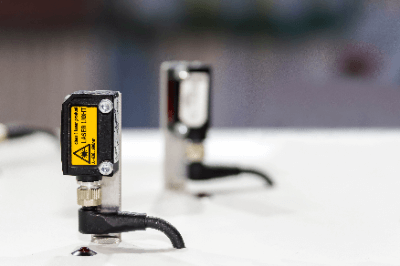

A laser sensor is a non-contact type of sensing device that uses a laser to measure the distance between the object to be measured and the sensor, as well as the thickness and height of the object itself.

A laser sensor is a non-contact type of sensing device that uses a laser to measure the distance between the object to be measured and the sensor, as well as the thickness and height of the object itself.

Since they are commonly used sensing devices, there are a variety of measurement methods and accuracies.

User of Laser Sensors

Laser sensors can be used to measure the distance between a processing or conveying device and the object to be measured when the distance to the object needs to be accurately determined. They are also used in situations where thickness information of the object to be measured is required, such as in product appearance inspections.

Thickness measurement can be performed with contact-type calipers, but if the object has a complicated shape or is inconvenient to touch, a non-contact type laser sensor can be used for non-destructive inspection.

Principle of Laser Sensors

In principle, laser sensors allow non-contact measurement, but there are several types of methods. When measuring the distance to a certain object to be measured, either a diffuse-reflective or a normal-reflective laser sensor is used.

In both cases, light from the laser source is reflected off the surface of the object to be measured, and the distance is determined by detecting the reflected light at the photosensitive area. The photosensitive area has a certain area width, and the photosensitive area varies depending on the angle of the reflected light. When the photosensitive area changes, a corresponding electric current is detected, and this information is used to convert it into a distance value.

Due to its structure, if the light source is incident to the surface of the object to be measured that is inclined beyond a certain angle, the reflected light will not be returned to the photosensitive area and, therefore, cannot be detected. This allowable tilt depends on the design of the displacement sensor, and in general, Laser Sensors with the diffuse reflection method have a wider detection angle.

How to Select a Laser Sensor

First, check whether the application is distance detection or acquiring shape information, such as thickness and height. If it is for distance detection, select a product that can measure at or above that angle from among those that match that measurement range, assuming how much the surface of the object to be measured is inclined. For thickness measurement, check the detection range.

Then, depending on how accurate you want the measurement itself to be, select the specifications for resolution, detection accuracy, and linearity. All of these factors affect measurement accuracy, and in general, the higher the accuracy, the more expensive the product, so be careful not to over-specify.

In addition to measurement accuracy, it is also a good idea to note whether the unit itself can be installed. If there is not enough space for the mounting area, it may be necessary to select a smaller Laser Sensor.

Other Information on Laser Sensor

1. Security System With Laser Sensor

A security sensor is a system to prevent the intrusion of suspicious persons. They are utilized in all kinds of places, such as condominiums, offices, and factories, and they are designed to sound an alarm when an intruder touches the sensor. Laser Sensors are currently widely used as security sensors.

There are two types of laser sensors: horizontal detection type and vertical detection type.

Horizontal Detection Type

The laser beam is emitted horizontally at 180 °C and covers a wide area. This type of monitoring system is suitable for open areas such as outdoors and detects moving objects. The monitoring range can be set to define areas to be excluded in advance.

Vertical Detection Type

This is a security sensor in which a laser beam is emitted vertically, covering a surface perpendicular to a wall or ceiling. This type of monitoring system is suitable for localized areas such as a passageway or in front of a door and detects objects that pass in front of the surface on which the sensor is working. The height of the object to be detected can also be set.

2. Disadvantages of Laser Sensor

Laser Sensors are convenient non-contact sensors that use light rays, but they may malfunction under some conditions.

Unevenness of the Surface of the Object to Be Detected

Laser sensors with a small spot may malfunction due to fluctuations in the amount of light received due to reflections caused by the unevenness of the surface of the object to be detected. If the surface of the object to be detected is uneven, use a sensor with a large spot.

Vibration

Vibration applied to the laser sensor may cause the optical axis to shift, resulting in a malfunction. Review the installation of the laser sensor and fix it with screws or auxiliary fittings, and install it as close to the object to be detected as possible to minimize the effects of optical axis misalignment.

Pulsed Light

Pulse lighting is a lighting method that repeatedly turns on and off. Since the light is turned on at a high frequency, it appears to the human eye as if the light is continuously turned on, although it is actually blinking.

Most laser sensors use pulsed light emitting lasers, which may malfunction against surrounding LEDs that pulse light as well as themselves. If there is a pulsing light nearby, it is important to install a shield between the sensor and the light receiving part or adjust the angle of the light receiving part so that the light does not hit the sensor.