What Is Thermal Analysis?

Thermal analysis is a collective term for analytical methods that investigate the temperature and time requirements for physical changes in substances during heating or cooling.

Components of Thermal Analysis Instruments:

- Detection Section: This section, equipped with a heater, sample holder, and detector (sensor), heats and cools the sample while monitoring its temperature and physical properties.

- Computer Section: Comprising a temperature control unit and a data processing unit, this section regulates the heater’s temperature and processes signals from the detector and temperature sensor, managing everything from data recording to analysis.

Modern thermal analysis devices are designed for efficient temperature control, data recording, and analysis, often featuring integrated control and analysis software.

Uses of Thermal Analysis

Thermal analysis is crucial for determining how material properties and effects vary with temperature. It aids in understanding material characteristics, establishing optimal usage temperatures, and setting appropriate manufacturing temperatures for products.

Materials respond to temperature changes through phase transitions, chemical reactions, and physical alterations. Utilizing thermal analysis to comprehend these responses is essential for developing materials with superior dimensional stability and optimizing processing conditions. It is also used in quality control to ensure that products meet predetermined specifications.

Principle of Thermal Analysis

Thermal analysis encompasses a variety of techniques, each tailored to detect specific physical properties:

- 1. Differential Thermal Analysis (DTA): Measures temperature differences against a reference substance, indicating changes like glass transition, crystallization, melting, and sublimation.

- 2. Differential Scanning Calorimetry (DSC): Assesses heat flow differences against a reference, useful for evaluating heat capacity and specific heat, and for observing changes and reactions.

- 3. Thermogravimetric Analysis (TG): Tracks weight changes, useful for detecting changes like sublimation, evaporation, and thermal decomposition. When combined with other techniques, it provides comprehensive insights.

- 4. Thermo-Mechanical Analysis (TMA): Measures deformation against temperature, helping to understand phenomena like thermal expansion and glass transition.

- 5. Dynamic Mechanical Analysis (DMA): Assesses dynamic mechanical properties, such as viscoelasticity, to understand molecular motion, structural changes, and thermal histories.

Other techniques like Evolved Gas Analysis (EGA) are also employed, with the choice of method depending on the sample and objectives. Advanced devices that combine multiple analytical methods have been developed, providing enhanced value and comprehensive insights.

Other Information on Thermal Analysis Measurements

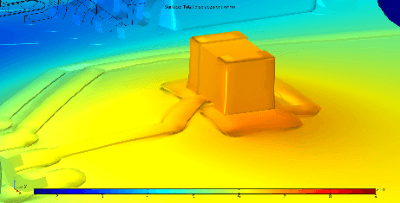

Example of thermal analysis measurement results: Heating a polymer material typically results in a series of transitions: glass transition, crystallization, melting, and eventual oxidation. By analyzing these stages with thermal analysis, sharp transitions in measured values can be observed, corresponding to these phenomena. This analysis aids in characterizing the material in question.

The outcomes of thermal analysis can vary depending on the physical properties being measured. Some methods may show distinct peaks, while others might not detect noticeable changes. Therefore, selecting appropriate measurement techniques based on the objectives and comparing results from different methods is crucial for accurate material evaluation.