What Is a Vacuum Tube?

Vacuum Tubes are special tubes used in high vacuum environments.

In vacuum applications, the tubing must operate with little or no gas in the tube or be completely evacuated. This eliminates the effects of gases and allows for a variety of advanced scientific research and industrial applications.

Applications for Vacuum Tubes

1. Semiconductor Manufacturing

Vacuum Tubes are an essential element in the semiconductor industry. The semiconductor manufacturing process requires a highly vacuumed environment, and Vacuum Tubes are used in processes such as etching and deposition. Vacuum tubes are used in processes such as etching and deposition, which enable the manufacture of high-precision semiconductor devices.

2. Space Exploration

Vacuum Tubes are used in space exploration equipment and satellites because of the extremely low-pressure vacuum conditions in space. Vacuum Tubes support reliable operation of these devices, which require reliability and durability under high vacuum conditions.

3. Precision Measurement Equipment

In scientific research and industry, there are times when minute measurements and evaluations are required. Vacuum Tubes are ideal for precision measuring devices and test equipment to eliminate the effects of gases and ensure high precision measurements.

4. Vacuum Refrigeration Vacuum Cooling

Vacuum Tubes can also be used for refrigeration and cooling processes. In a vacuum environment, the conduction of heat is reduced and the cooling effect of the material or sample is improved. Vacuum Tubes can be used for more efficient cooling.

5. Mass Spectrometry

The mass spectrometer is an important device used to determine the composition and composition of materials. Vacuum Tubes are used to hold the sample in a vacuum to ensure accurate mass spectrometry.

6. Laser System

In laser systems, light amplification and induced emission take place under vacuum conditions. Vacuum Tubes assist in the propagation of light in laser systems and improve the performance of lasers.

Principle of Vacuum Tube

1. Exclusion of Gases

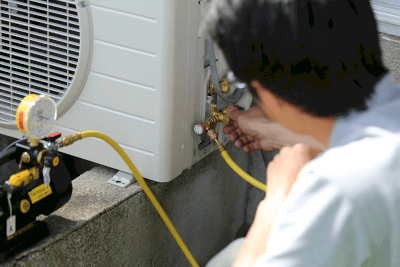

Vacuum Tubes are important to achieve a high vacuum environment by eliminating gases from the inside of the Vacuum Tube. Vacuum Tubes are usually equipped with a special pump inside which gases are sucked out to create a vacuum. The elimination of gases results in a very low pressure inside the Vacuum Tube, creating a vacuum.

2. Leakage Prevention

Vacuum Tubes must be extremely airtight, so it is important to prevent leaks. The entire structure of the tubing, including joints and packings, must be airtight. Leaks make it difficult to maintain a vacuum and prevent accurate operation of the equipment.

3. Reduced Heat Transfer

Vacuum Tubes have the characteristic of reduced heat conduction in a high vacuum environment. Under normal atmospheric pressure, heat is transferred through air, but in a high vacuum condition, there is less gas present, so heat conduction is suppressed.

This changes the thermal properties of the object or sample inside the Vacuum Tube, enabling efficient control of heat.

4. Heating and Evaporation

Some Vacuum Tubes operate on the principle of heating and evaporation. An internally installed heater heats the sample or material, thereby producing gas or vapor.

This process makes it possible to control the pressure and composition of the Vacuum Tube.

5. Gas Introduction

In some experiments or processes, it is necessary to introduce certain gases into the Vacuum Tube. In this case, a controlled gas introduction device is used.

By introducing specific gases in precise amounts, it is possible to observe the reactions and behavior of the sample and to advance the research or manufacturing process.

Types of Vacuum Tubes

1. Ejector Tube

An ejector tube is a type of tube that uses a high-speed air stream to generate a vacuum. There is a nozzle inside, and compressed air or vapor is discharged at high speed by the nozzle, sucking in the surrounding gas and forming a vacuum.

The structure is simple and does not require electric power for operation, thus energy-saving vacuum generation is possible. It is mainly used in exhaust systems and air pumps.

2. Diffusion Pump

A diffusion pump is a type of tube that uses molecular diffusion to eliminate gas. There is a heater and cooler inside, and gas molecules collide with each other and adsorb and desorb on the wall, thereby eliminating the gas.

It is used in high vacuum areas and is suitable for achieving high vacuum levels. This type is mainly used in semiconductor manufacturing and vacuum plating.

3. Turbo Molecular Pump

Turbo molecular pumps are a type of tube that uses high-speed rotating turbo molecules to eliminate gases. Molecules are eliminated by the rotation of the turbo molecules to form a high vacuum area.

Because they can achieve extremely high vacuum levels, they are used for advanced experiments and processing. These products play a particularly important role in semiconductor manufacturing and the aerospace industry.

4. Ion Pump

Ion pumps are a type of tube in which ionized gas is excluded by an electric field. Ion pumps have electrodes inside, and ionized gas is attracted by the electric field and ejected from the tube.

In addition to achieving a high degree of vacuum, it is also effective in removing rare gases and water vapor. It is mainly used in vacuum refrigerators and electron microscopes.