What Is Vacuum Deposition Film?

Vacuum deposition film is a product formed as a thin film by evaporating metals, such as aluminum or oxides, such as silica.

Vacuum deposition film is a product formed as a thin film by evaporating metals, such as aluminum or oxides, such as silica.

By changing the evaporation substance, film thickness, and film material, functions can be added to meet various purposes. There are two main vapor deposition methods: physical vapor deposition and chemical vapor deposition, and the appropriate method is selected according to the substance to be used and the product manufacturing method.

Applications of Vacuum Deposition Film

Vacuum deposition film can have various functions depending on the composition of the film base material and the film to be vacuum deposited. For example, aluminum vacuum deposition film is a product that forms a thin film of aluminum on a film.

This film has functions such as water vapor barrier, oxygen barrier, and light blocking. Vacuum deposition film is used for precision equipment such as electronic components, labels for food and beverages, bags for confectionery and retort pouch food, and supplements.

Silica vacuum deposition film is a product that forms a thin film of silicon oxide on the film. It has excellent gas barrier properties, aroma retention, and chemical resistance, making it useful for printing and packaging purposes.

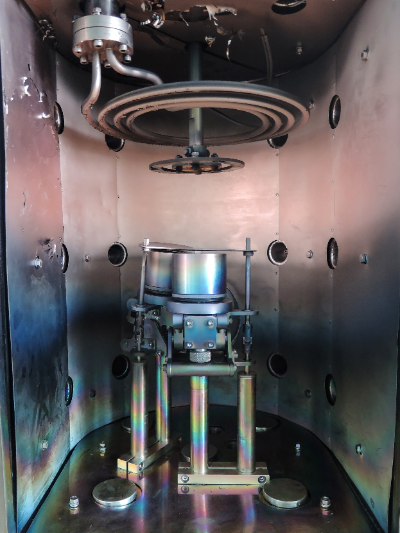

Principle of Vacuum Deposition Film

Vacuum deposition film is a generic term for products that form a layer on a plastic substrate (film) by evaporating a substance. Metals (aluminum, silica, etc.) and oxides are used as evaporation substances.

By attaching these substances to the surface of the film as a thin film, new functions, such as barrier properties and design properties, can be added without changing the properties of the base material. There are two methods of deposition: physical vapor deposition (PVD) and chemical vapor deposition (CVD).

PVD is a method of thin film deposition through physical reactions such as heating or impact and includes methods such as vacuum deposition and sputtering. On the other hand, CVD is a method of thin film deposition by chemical reaction of gaseous raw materials, and methods such as thermal CVD and plasma CVD are commonly used.

Various polymer materials are used as film substrates, such as PE (polyethylene), PP (polypropylene), and PET (polyethylene terephthalate), depending on the application.

Types of Vacuum Deposition Film

Vacuum deposition film is available in a variety of types, so it is important to select the type that best suits the application and environment in which it will be used.

1. Aluminum Vacuum Deposition Film

Aluminum vacuum deposition film maintains the freshness and quality of food products with its excellent barrier performance, and prevents moisture and oxygen from entering from the outside. Its light-blocking properties also prevent the deterioration of foods and products due to light and heat.

It plays an important role in food and pharmaceutical packaging, where long-term preservation and quality maintenance are required.

2. Silica Vacuum Deposition Film

Silica vacuum deposition film prevents the permeation of gases, such as oxygen and water vapor with its excellent gas barrier property. This enables food and pharmaceutical products to retain their freshness and quality for a long period.

In addition, its aroma-retaining properties keep the aroma and taste of foods and products intact. In addition, silica vacuum deposition film has excellent chemical resistance. It shows high durability against chemicals and agents, and is sometimes used for packaging products and reagents.

3. Chrome Vacuum Deposition Film

The distinguishing characteristic of chrome vacuum deposition film is its high reflectivity. Chromium effectively reflects visible and infrared light, providing a mirror-like luster and brightness.

This property is an important factor in the manufacture of mirrors and reflectors, and is widely used in fields such as optical devices and lighting equipment.

4. Copper Vacuum Deposition Film

Copper is a highly conductive metal and can efficiently transmit electrical signals. Vacuum deposition film plays an important role in the manufacture of electronic components by utilizing this property to form electrical connections and circuits.

They are widely used in telecommunications equipment, semiconductor devices, and other fields to meet requirements for high-speed data transmission and high-frequency signal transmission.

5. Gold Vacuum Deposition Film

Gold is a precious metal with very high electrical conductivity, making it suitable for electrical signal transmission and electrical connections. Vacuum deposition film is useful for contact pads and contact areas of electronic devices, as well as for high-definition wiring.

Its high electrical conductivity minimizes signal loss and noise generation, supporting the realization of high-performance electronic devices.

6. Titanium Vacuum Deposition Film

Titanium vacuum deposition film is a thin film formed by evaporating titanium and is characterized by its abrasion and corrosion resistance. Vacuum deposition film is a hard metal and is resistant to friction and scratching.

It also forms a titanium dioxide layer, which is effective in protecting against chemical agents and the environment. This allows it to be used to improve the durability of decorative and industrial surfaces, automotive parts, and biomedical devices.

Titanium plays an important role in medical devices and artificial joints due to its high biocompatibility and compatibility with biotechnology.