What Is a Film Inspection Machine?

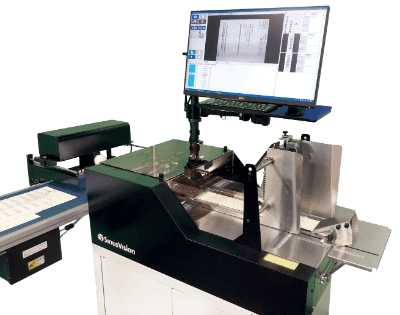

A film inspection device is a device that inspects for defects that occur during the production of sheets and films.

A film inspection device is a device that inspects for defects that occur during the production of sheets and films.

In our daily lives, films and sheets are used for foodstuffs, home appliances, household goods, and many other applications. On the other hand, most of them are made very thin. However, they are strong enough and do not tear easily.

By adding a film inspection machine to the production line, defects can be inspected during production to ensure that the sheet is up to standard.

Uses of Film Inspection Machines

A film inspection machine is mainly used to check and inspect sheets for various defects and deficiencies in the manufacturing process. Film inspection machines are installed at various stages of the sheet manufacturing process.

In the film forming process, they inspect the base resin for contamination and fish eyes. In the laminating process, they inspect for inclusions and wrinkles. In the coating process, they inspect the application of chemicals. In the slitter and inspector processes, they perform final shipping inspections. Finding various defects in the manufacturing process is effective in maintaining product quality, preventing defects in subsequent processes, preventing yield loss, and improving productivity.

In recent years, the system has also been used to inspect optical sheets, multilayer sheets, high-performance sheets, coated paper, flooring materials, glass sheets, metal foil sheets, nonwoven fabrics, etc., for defects that are difficult to see with the naked eye.

Principle of Film Inspection Machine

Although there is no clear definition, the difference between a sheet and a film is often distinguished by their thickness. In this section, all descriptions are for “sheets.”

1. Sheet Production

Sheets are manufactured from resins, such as polyethylene using an extruder. In this process, the sheet is stretched from a T-die into a thin slit, cooled by a cooling roll, and wound up by a winder to be completed as a product.

This is called the T-die method. Another method is the inflation method, in which air is used to inflate the sheet into a bag-like shape after cooling to make two overlapping sheets.

2. Inspection of Sheet Defects

In the process of manufacturing these sheets, various defects such as thickness variation, color irregularity, fisheye, foreign matter such as dust and oil adhesion, wrinkles and stripes, scratches, pinholes, stains, and filling defects occur. Film inspection machines detect these defects.

In camera-based inspection, an area camera is used to view the entire area to be inspected, and a line camera is used to inspect the line to be inspected all at once. A line camera is best suited for continuous inspection in a line where sheets are flowing.

Multiple high-resolution line cameras are installed in the sheet width direction, and the sensitivity threshold of each camera is set according to the variation in the sheet geometry. Another method is to use a single scanning camera and inspect by high-speed scanning.

It is also important to select an inspection device according to what is to be inspected, such as a device that inspects thickness using a laser beam and a reflective laser displacement meter.

Other Information on Film Inspection Machines

1. Purpose of Film Inspection Machines

The purpose of installing film inspection machines is to ensure the detection of defects by mechanizing inspections, to improve product quality by reducing human errors, and to increase productivity.

Examples of Inspections by Film Inspection Machines

High-Speed Inspection of Sheet Defects

The system consists of three-line cameras, transmissive and reflective LED line lighting, etc. Two cameras are used to inspect the front and back surfaces of the sheet, and one camera is used to inspect and detect defects at high speed using transmissive and reflective LED line lighting.

Detection of Uneven Coating Defects

When coating a sheet, slight variations in thickness can cause uneven coating defects. Film inspection machines using a multi-wavelength camera can clearly detect uneven coating due to the difference in color components.

Wrinkle Defect Detection

When manufacturing transparent sheets, wrinkle defects may occur due to sheet warpage. Wrinkle defects are difficult to detect with monochrome images because the difference between a flat surface and a defect is small. Wrinkle defects can be detected clearly by acquiring RGB images using a multi-wavelength camera.

Discrimination of Foreign Matter and Air Bubbles

When laminating sheets, it is necessary to distinguish slight air bubbles from foreign matter. In monochrome inspection, shiny foreign matter and bubbles cannot be discriminated because they are the same light defect.

However, inspection with a multi-wavelength camera can detect differences in shading information, making it possible to discriminate between them.