What Is a Gas Generator?

A Gas Generator is a device that generates various types of gases.

Gas can be supplied in various ways depending on its use, such as for household or manufacturing purposes. One of the on-site supply methods is by means of a Gas Generator. The conditions of use, such as the amount of gas used and the required pressure, vary widely.

Therefore, the equipment itself can range from compact to sophisticated. For example, in the case of oxygen, depending on the desired usage volume, the supply method can be selected from the following: liquefied gas lorry supply to a cylinder, low-temperature liquefied gas container, or cold evaporator CE; or piping supply by Gas Generators such as deep cold air separators or oxygen PSAs.

Uses of Gas Generators

Small-scale Gas Generators that only require a power supply are useful when a small amount of gas is used continuously at a steady flow rate. Products such as personal computers that contain semiconductors require nitrogen and various electronic material gases in the manufacturing process.

- Semiconductor manufacturing

- For ozone generators (water treatment, drifting, etc.)

- For live fish breeding and transportation

- For bio-related, cultivation and fermentation

- For furnace blowing (steelmaking, nonferrous metal melting, etc.)

- For metalworking and brazing burners

- For paper manufacturing industry (drifting)

- For combustion equipment

- Oxygen gas for air conditioning and health care

- Water treatment (oxygen aeration)

- For hydrogen sulfide generation control

- For glass processing burners

- For oxidation chemical reaction

- For cooling power plant turbines (refrigerant)

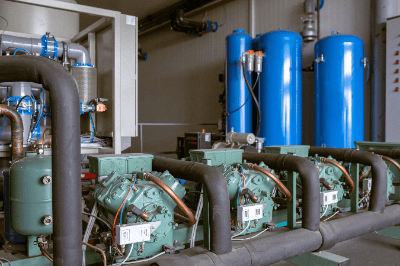

Principles of Gas Generators

Gas Generators differ widely in their production methods and principles.

1. Oxygen Gas Generator (PSA Type)

In order to efficiently obtain high-purity oxygen, PSA-type oxygen gas generators adsorb and remove nitrogen from the air by utilizing the fact that the equilibrium adsorption capacity of nitrogen and oxygen in adsorbents such as synthetic zeolite differs greatly under pressure. This method is called the pressure swing adsorption PSA method.

2. Nitrogen Gas Generator (PSA Type, Gas Separation Membrane Type, Deep Cooling Type)

Nitrogen Gas Generators remove oxygen and moisture from the air to generate high-purity nitrogen. Three main types are used.

PSA Type

Using molecular differences, microporous adsorbents such as zeolite and activated carbon are used to separate nitrogen and oxygen molecules. Two adsorption columns are prepared, and by alternately repeating adsorption and regeneration, nitrogen can be continuously extracted. This is convenient for use of high-purity nitrogen.

Gas Separation Membrane Method

Hollow-fiber membranes are generally used, utilizing the property that oxygen is more permeable than nitrogen in the air. Separation is performed by using the difference in the passage speed of molecules. Convenient for use with low-purity nitrogen.

Deep-Cooling Type

This method separates components in air based on differences in boiling points. The boiling point at which a liquid becomes a gas is -183.0°C for oxygen and -195.8°C for nitrogen, and this difference is used for separation.

3. Hydrogen Gas Gas Generator

There are various methods for producing hydrogen gas. Methods such as reforming fossil fuels, recovering and refining hydrogen generated as a byproduct of chemical plants, and electrolyzing water are in practical use.

The method of producing hydrogen by decomposing and reforming fossil fuels such as coal and petroleum at high temperatures has the disadvantage of emitting CO2 during production. CO2 emissions can be reduced by using technologies that capture the CO2 generated and store it underground or use it.

Water electrolysis methods can reduce CO2 emissions to zero through the use of renewable energy. Hydrogen of high purity can be produced by using platinum catalysts, etc. for electrodes.

4. Other

Hydrogen/Carbon Monoxide Gas Generator is available. It uses natural gas, carbon dioxide, and oxygen as raw materials to generate a H2/CO = 1:1 gas mixture.

The H2/CO gas can be purified using a special adsorbent to produce high-purity carbon monoxide gas, which can be used as a reducing agent for metals, in chemical synthesis using methane and methanol as raw materials, and in the production of naphtha, kerosene, and diesel oil from natural gas.