What Is an Insulated Crimp Sleeve?

An insulated crimp sleeve is a crimp sleeve with an insulated surface. It is mainly used to connect wires at intermediate points.

The insulation coating electrically insulates the wires from other circuits and components, preventing electrical contact with the external environment. This prevents electrical shorts and leakage, and also ensures safety.

It also protects conductors from external factors such as vibration and chemicals, preventing damage and deterioration. It can also improve various performance characteristics, such as wear resistance.

However, it is important to install the sleeves correctly. Using a crimping tool, the sleeve must be securely fastened to the conductor. If not correctly installed, the insulating and protective effects are likely to be compromised.

Uses of Insulated Crimp Sleeves

Insulated crimp sleeves are used in a variety of industries. However, all of them are used for electrical wiring connections. They are not used for any other purpose.

They are generally used for repairing wiring. When wiring fails due to wire breakage, etc., it may be connected at an intermediate point for collection. By using insulated crimp sleeves for collection, it is possible to electrically connect the failed wiring while insulating it from the external environment by means of the insulated coating.

They may also be used when relocating equipment. When relocating industrial equipment that is in fixed use, it is not uncommon for the length of electrical wiring to be insufficient. By using insulated crimp sleeves, the same type of wiring can be spliced together.

They are used in a wide range of industries, from construction to the automotive industry. In buildings, they are used to connect in-wall wiring, while in automobiles they are used to connect harnesses.

Principle of Insulated Crimp Sleeves

Insulated crimp sleeves generally consist of two main parts: the insulation and the conductor. The insulation coating and the conductor.

1. Insulation Coating

The insulation coating is located on the outside of the sleeve and insulates and protects the conductor. Insulation performance is achieved by using an insulation coating such as vinyl chloride or nylon. Rubber and other materials may also be used.

It provides electrical insulation and cuts off electrical contact between the conductor and the external environment. This prevents electrical shorts and leakage currents.

It also provides physical protection and shields the conductor from the outside environment. The insulation coating serves to protect the conductor from elements such as friction and moisture.

2. Conductors

The conductor is the part of the sleeve that is inside and is responsible for transmitting electrical signals and power. It is generally made of metal and must be conductive and durable. Since adhesion to the wires is also important, soft materials such as oxygen-free copper are often used.

When making connections with wires, the use of crimping tools is recommended. Crimping with a crimping tool is called crimping. By using crimping pliers that are appropriate for the size of the joint of the crimped terminal, it is possible to make a tight fit and connection with normal power.

The wire is inserted into the crimped portion of the terminal with the insulation covering stripped away and the conductor exposed. Appropriate pressure is applied using a crimping tool to firmly secure the wire so that the conductors are in direct contact with each other. The wire connection section ensures a secure connection between the wire and the insulated crimp sleeve.

How to Select an Insulated Crimp Sleeve

When selecting an insulated crimp sleeve, it is important to consider the sleeve diameter, insulation material, and shape.

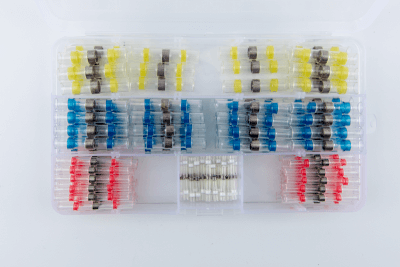

1. Sleeve Diameter

Sleeve diameter is the size of the conductor sleeve. Recommended wire diameters are listed in catalogs, etc. Generally, selection is based on the diameter of the wires to be connected. It is important to select a sleeve with a sufficient diameter even when multiple wires are to be crimped together.

2. Material

The material of the insulation coating should be selected from nylon or polyvinyl chloride. In general, nylon has a higher heat resistance temperature.

3. Shape

Various shapes of insulation sheaths are available. In general, straight sleeves are often selected. When wiring is detached, plug-in connection sleeves may be selected.