What Is a Dust Collecting Circular Saw?

A dust collecting circular saw is a conventional electric circular saw with dust collecting capability.

It can work while vacuuming dust, and chips generated during material cutting. It is also called a dust-proof circular saw.

It is especially suitable for cutting plasterboard and siding board, where dust can be scattered. The work environment is kept clean, so the effect on the respiratory organs is minimized and workers are protected from health hazards. It also reduces cleaning labor.

Since there is no dust impact on the surrounding environment, other work can proceed in parallel.

Uses of Dust Collecting Circular Saws

Dust collecting circular saws are often used for cutting plasterboard and siding board, which tend to generate dust. They can also be used for a variety of other materials, including wood, metal, and plastic. It is important to select the appropriate chip saw depending on the material.

They are used in a wide range of situations such as construction sites, remodeling, furniture making, and DIY. Since dust and chips do not scatter, they are preferred by those who do not want to contaminate the work site, those who want to prevent health hazards, and those who want to make cleaning easier.

Principle of Dust Collecting Circular Saws

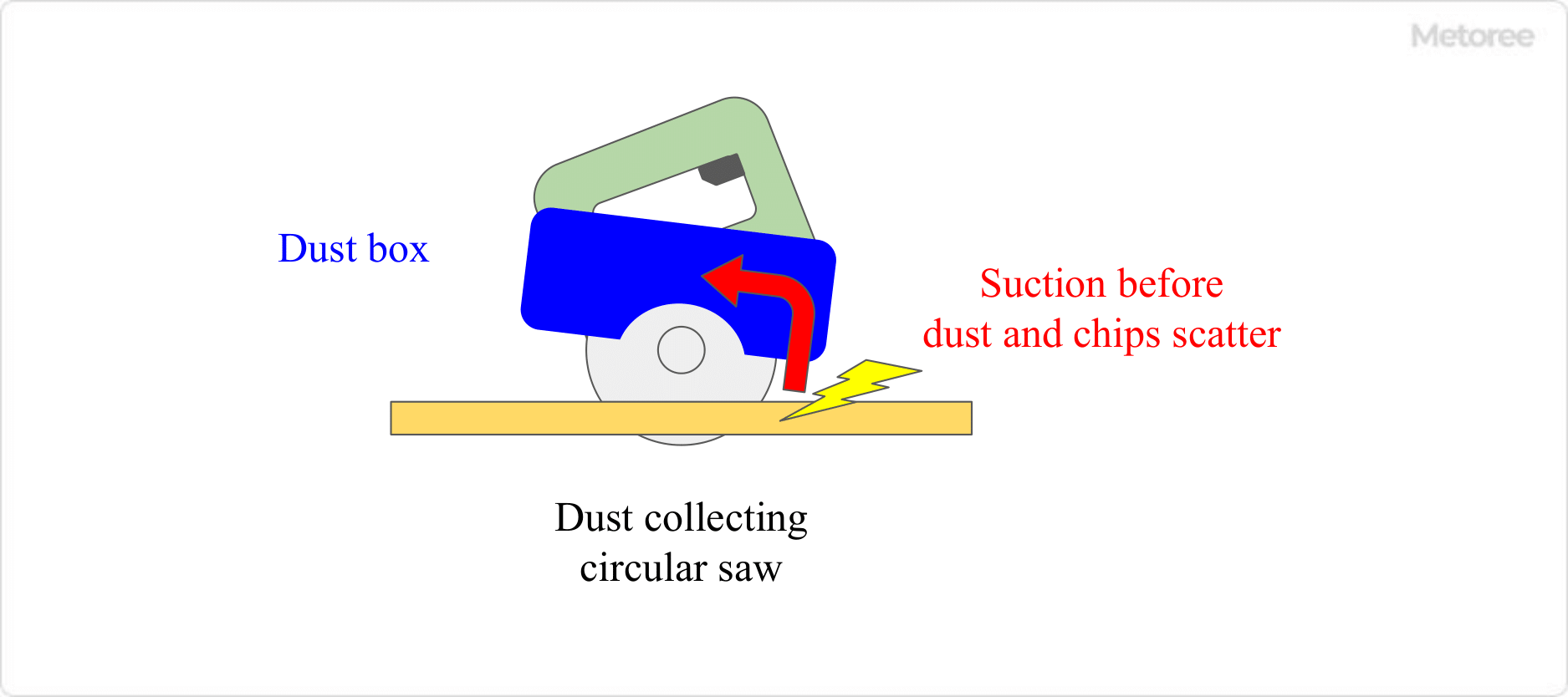

Figure 1. Principle of dust collecting circular saw

Dust collecting circular saws have a dust collecting suction port located near the cutting section. This ensures that dust and chips are sucked out before they scatter, keeping the work environment clean.

Dust and chips sucked in through the suction port are collected in a dust box provided with the main unit or in an external dust collector.

How to Select a Dust Collecting Circular Saw

The following three points should be considered when selecting a dust collecting circular saw.

1. Cord Type / Battery Type

There are two types of power supply for dust collecting circular saws: cord-type and battery-type. The cord type allows you to work without worrying about battery capacity, but the cord makes it somewhat inconvenient to handle.

The battery type is easier to operate because there is no need to worry about the cord. When working for a long time, it is recommended to have spare batteries.

2. Dust Box Type / Dust Collector Connection Type

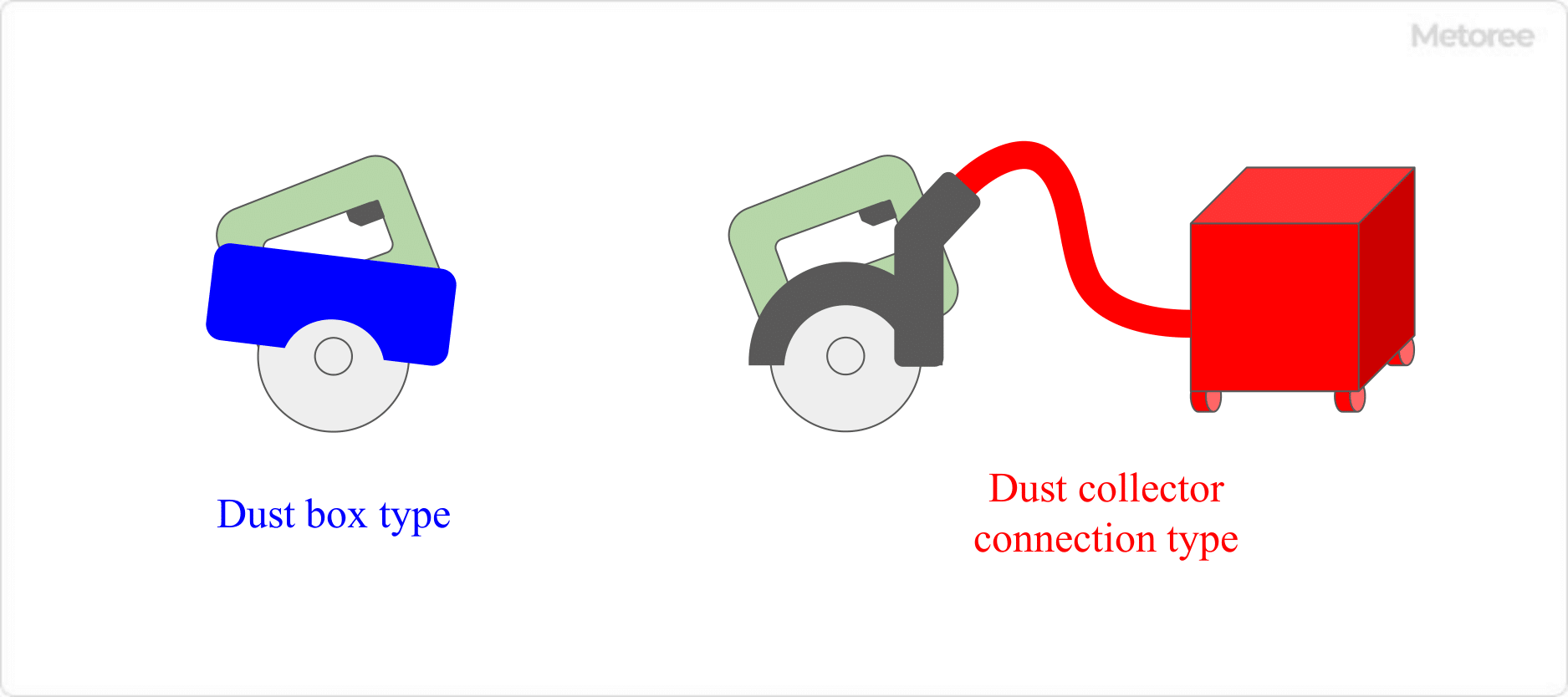

Figure 2. Dust box type and dust collector connection type

There are two types of dust collecting circular saws: a dust box type installed in the main unit and a type connected to an external dust collector. The dust box type can be used independently, making it easy to carry and easy to work with. However, its capacity is smaller than that of a dust collector, and it is necessary to dispose of waste frequently.

The dust collector-connected type has a higher dust collection rate and larger capacity than the dust box type. Since the dust collector is connected with a hose, operability is slightly worse.

3. Outlet Interlocking Type / Wireless Interlocking Type

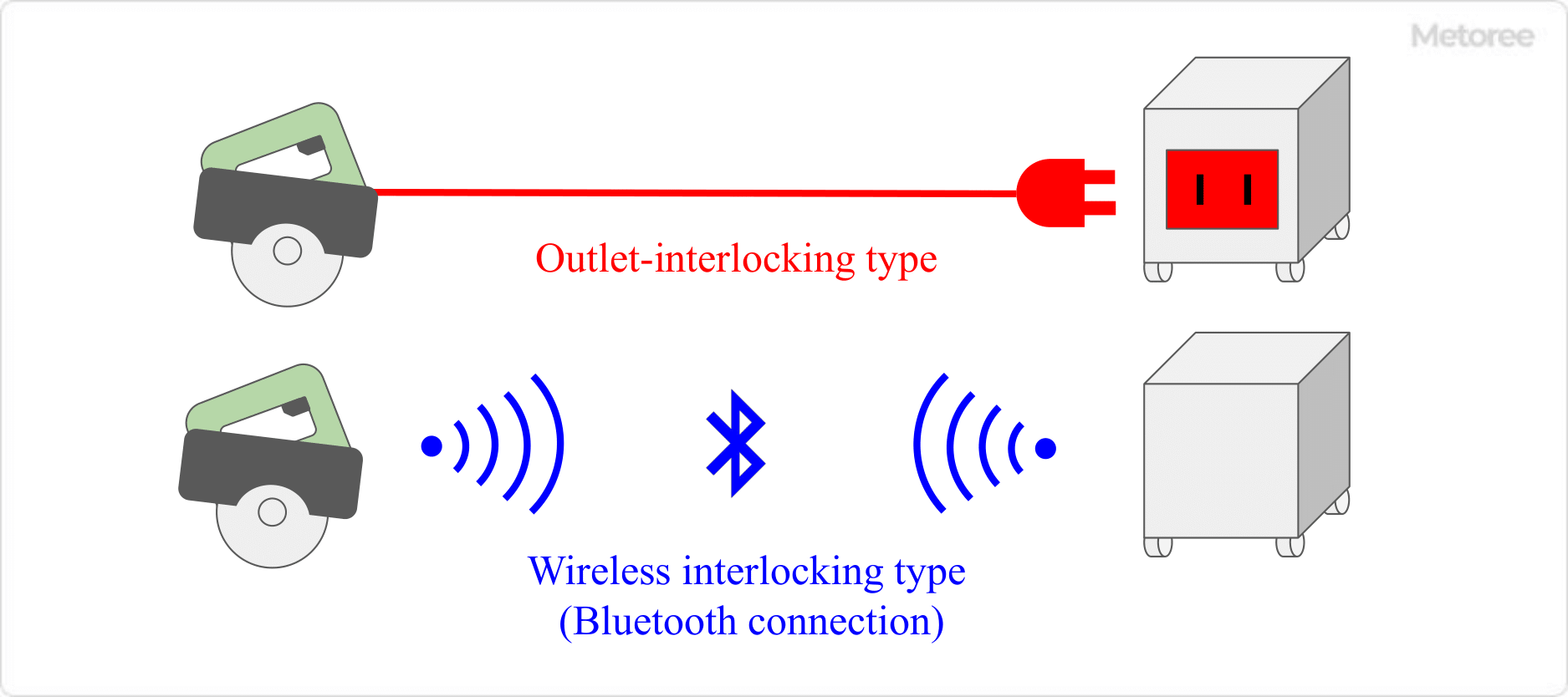

Figure. 3 Outlet-interlocking type and wireless interlocking type

There are two types of dust collector connection types: the outlet type and the wireless type. In the outlet-connected type, the power source for the dust collecting circular saw is taken from the dust collector, thereby interlocking the switch between the circular saw and the dust collector.

The wireless interlocking type enables wireless interlocking of the switch by connecting the dust collecting circular saw and the dust collector via Bluetooth.

Other Information on Dust Collecting Circular Saws

How to Use the Dust Collecting Circular Saw

The dust collecting circular saw can be used in the following four major steps.

1. Preparing the Dust Collecting Circular Saw

First, attach the appropriate chip saw to the dust collecting circular saw for each material, such as plasterboard, siding board, wood, and metal. Next, adjust the blade’s extension according to the thickness of the material to be cut.

It is appropriate for the blade to protrude 3 to 5 mm from the material. If an external dust collector is used, make sure the hose is securely connected.

2. Preparation for Cutting

Place the material to be cut on a stable stand and secure it with a clamp or vice. Mark the cutting line on the material, before cutting.

If the cut-off side is too large, the material may deflect and pinch the blade, causing kickback. It is necessary to prepare a support material or other platform for the cut-off side as well.

3. Cutting Operation

It is important to maintain the proper speed and direction of travel during cutting operations. If too much pressure is applied to the blade or the direction of travel is bent, the blade and material will engage, causing kickback.

To avoid injury or accident in the event of kickback, do not stand directly behind the cutting line. Cords, hoses, etc. should also be avoided.

4. After Cutting Work Is Finished

After the work is finished, dispose of any debris in the dust box or dust collector. The blades should also be inspected and maintained, cleaning them if dirty or replacing them if worn.