What Is an IC Socket?

An IC Socket is a socket component in which the leads of an IC package are connected on the board without soldering and can be plugged and unplugged.

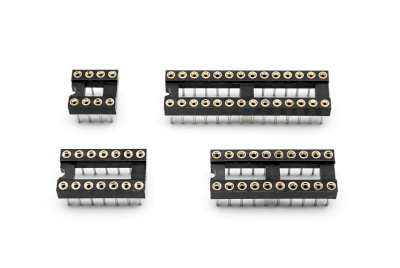

IC Sockets are available in a variety of shapes to suit a wide range of IC leadframes and are designed to be directly inserted and removed.

An IC is an ultra-miniaturized semiconductor element, such as a transistor, capacitor, resistor, etc., integrated into a small silicon chip. Generally, silicon chips made as ICs are connected to conductive lead frames with wires and covered with a resin mold.

Uses of IC Sockets

IC Sockets are used to connect the leads corresponding to each terminal of IC components in resin mold packaging to the motherboard without soldering and are mainly used on boards for prototyping electronic devices.

Since the IC socket itself is soldered to the board and used as a receptacle socket for inserting and removing IC components, it is often used when there is a possibility of IC modification, such as during circuit prototyping, or when the IC is not to be soldered directly to the board. There are many examples.

For example, when a manufacturer writes data to a memory and has it delivered, and another manufacturer mounts the memory, the IC socket can be used to write the data to the memory without directly soldering the elements to the board.

IC Sockets are also often used when only the ICs need to be changed frequently and the evaluation board or system board does not need to be changed, thus reducing the working hours required for IC soldering.

Principle of IC Sockets

The principle of IC Socket is to maintain electrical and physical contact between IC leads and contacts inside the socket without soldering. There are several methods of making contact with the IC leadframe.

1. Plate Spring Type

In the plate spring type, the leads of IC package components are sandwiched between two plates from both sides.

2. Round Pin Type

The round pin method uses internal contacts to make contact with the leads of IC package components. While the leaf spring type makes contact with the IC lead with a surface, the round pin type makes contact with the IC lead at several points, which provides better retention and is advantageous against vibration and shock. However, the cost of the round pin IC Socket itself is slightly higher than that of the plate spring type.

3. Zero Pressure Method

The zero-pressure IC socket is designed to allow easy insertion and removal of ICs. The IC socket is equipped with a lever and a switch for insertion/removal, and the operation of this lever fixes or frees the IC leadframe.

Compared to the spring type or round pin type, the zero-pressure type sockets can be inserted and removed more frequently, and are often used for applications that require frequent insertion and removal, such as IC testing and ROM writers.

When soldering a zero-pressure IC Socket, the contacts are soldered in the open state. Soldering with the contacts closed may cause contact failure.

Other Information on IC Socket

1. Multi-Pin Compatible Products

In addition to lead frame type IC packages, there are also multi-pin packages called LGA (land grid array). This type of IC package does not have leaded terminal connections, but has terminals arranged in a grid pattern on the backside of the package, and has pads in a grid pattern not only on the edges of the IC package but also on the inside surfaces.

LGA is inherently superior in its ability to handle high pin counts, and because there are no leads, it is free from the effects of parasitic inductors, making it suitable for high-frequency signals.

2. Heat Dissipation Design of IC Socket

When backside pins are connected with sockets, the heat dissipation design is extremely important for packaged products with ICs mounted on both sides on the backside, and for power ICs that handle high currents. It is also very important to pay attention to thermal design, such as the use of a built-in heat sink for heat dissipation, etc. For high current pins, the maximum rated current must also be carefully considered to prevent the pins from melting and breaking.