What Is Gland Packing?

Gland packing is a sealing material that is attached to the outer surface of a rotating or reciprocating shaft to seal the inside and outside of a machine or facility.

Gland packing is used for shaft sealing of shaft penetrations in machinery and equipment. Gland packing is defined as “a generic term for packing that is square or round in cross section and used for stuffing into stuffing boxes.”

Note that gland packing is not a perfect axial seal and is subject to some leakage. In pumps, however, leakage between the shaft and gland packing may be necessary to lubricate and cool the gland packing.

Principle of Gland Packings

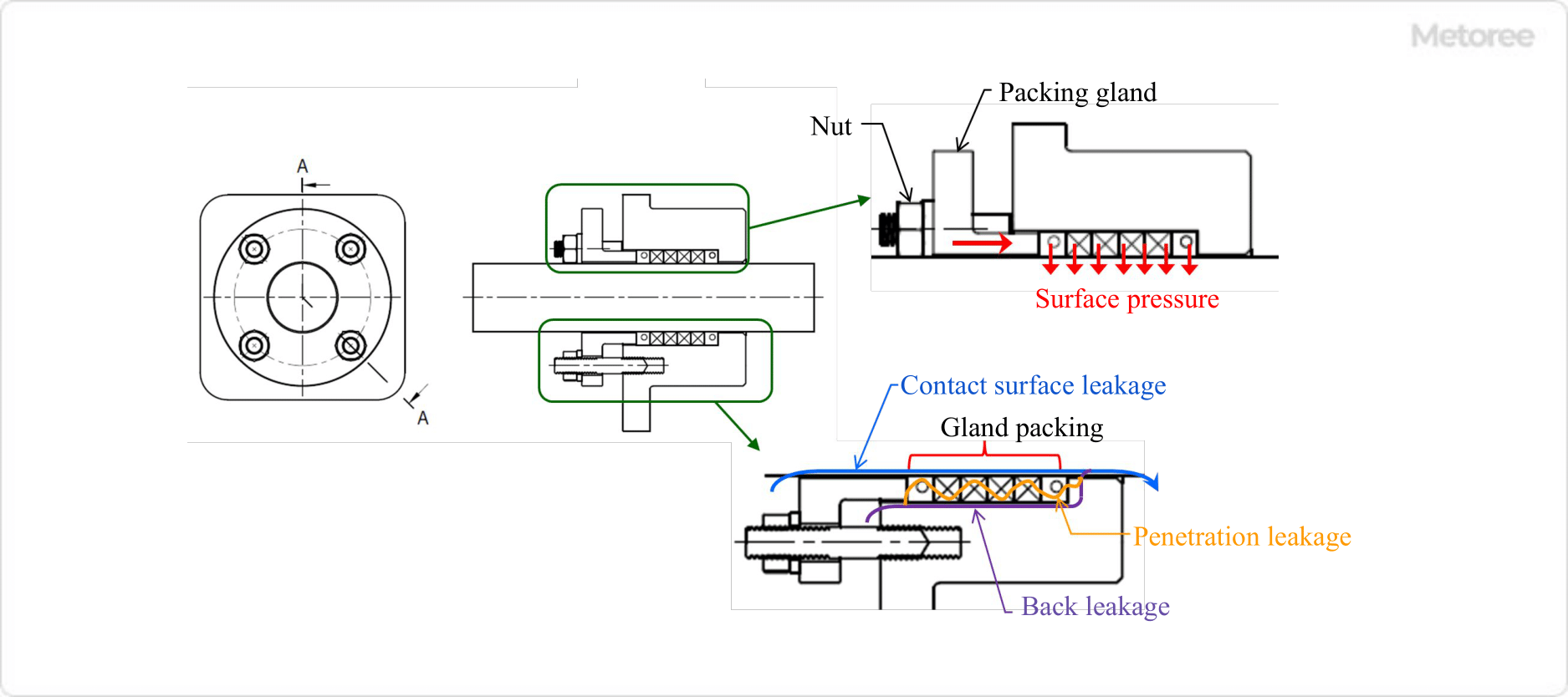

The gland packing principle of the gland packing is that the inner surface of the gland packing (shaft side) adheres to the outer surface of the shaft and the outer surface of the gland packing (housing side) adheres to the inner surface of the stuffing box, filling the gap between them and preventing fluid leakage by the contact surface pressure.

Figure 1. Principle of gland packing

The above surface pressure is caused by the gland packing being pushed by the packing gland (the part that holds the packing) when the nut is tightened, causing the gland packing to expand in the inner and outer radial directions. The more strongly the nut is tightened, the higher the surface pressure.

If the nut is tightened too much, the frictional resistance due to adhesion becomes too high, and a large load is placed on the rotating or reciprocating shaft. Care must be taken because this may interfere with the operation of the equipment. However, if the tightness is too weak, the fluid will easily leak.

There are three types of gland packing leakage, as described below.

- Leakage at contact surface. Leakage flowing between gland packing ID side and shaft OD side

- Leakage at the back. Leakage flowing between the outer diameter side of the gland packing and the inner diameter side of the stuffing box

- Seepage leakage. Leakage inside gland packing, mainly through the braided gaps in the braided packing

Uses of Gland Packing

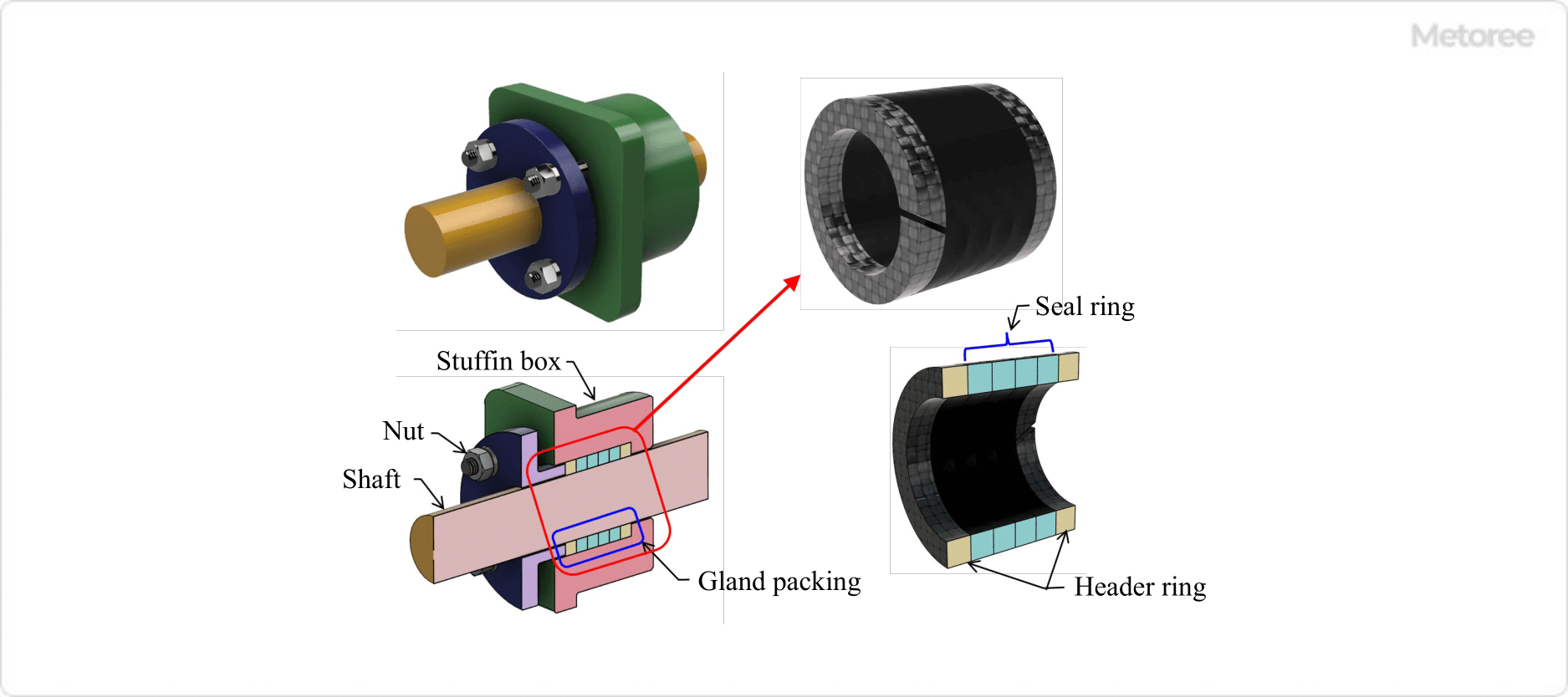

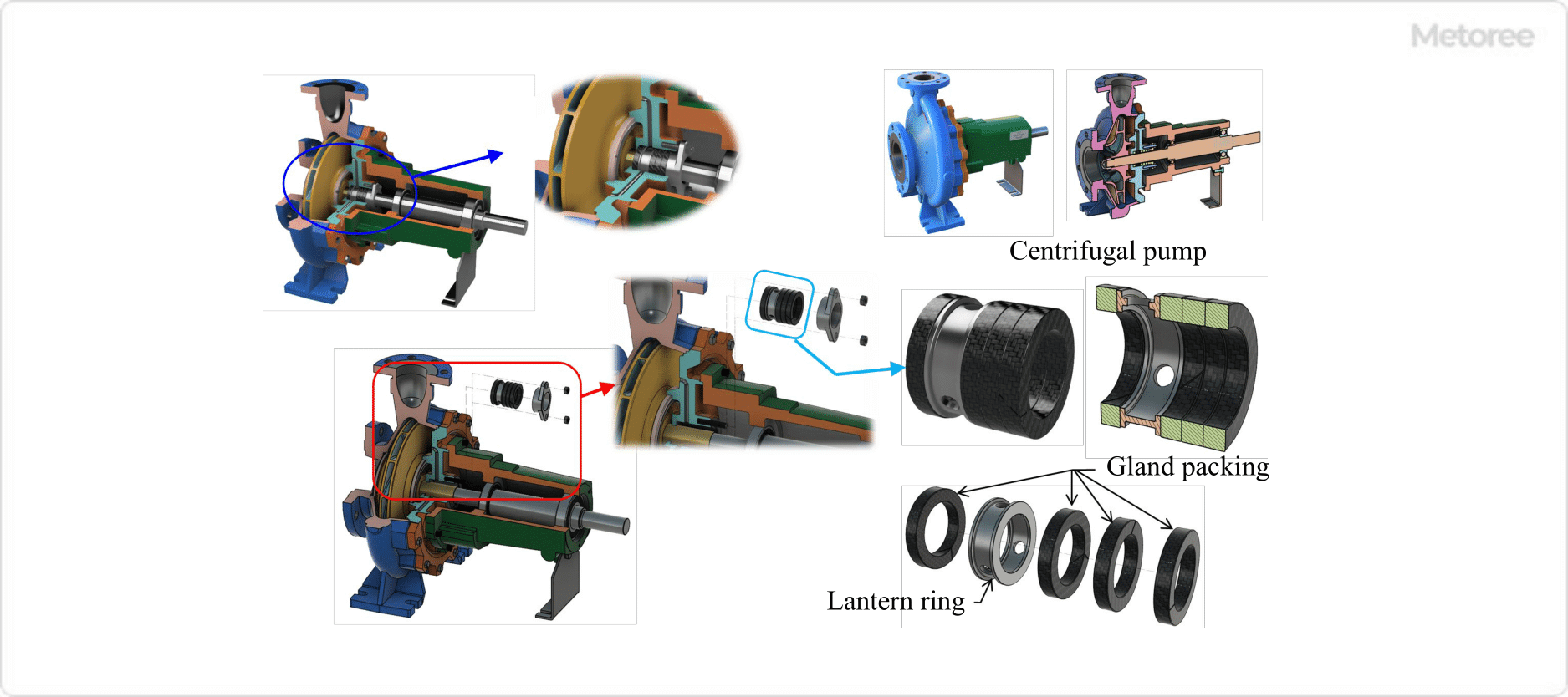

Figure 2. Example of gland packing use

Gland packing is used in rotating or reciprocating machinery or equipment where the shaft protrudes externally through a housing or casing. These parts are used to prevent oil fluids, gases, and other gases inside the machine or equipment from leaking to the outside.

Insert the gland packing into the housing or casing stuffing box (the box that contains the packing) so that it wraps around the outer circumference of the shaft at the shaft penetration area. Push the gland packing into place by tightening the nut at the packing gland (the part that holds and tightens the packing) so that the inside surface of the gland packing is more tightly pressed against the outside surface of the shaft.

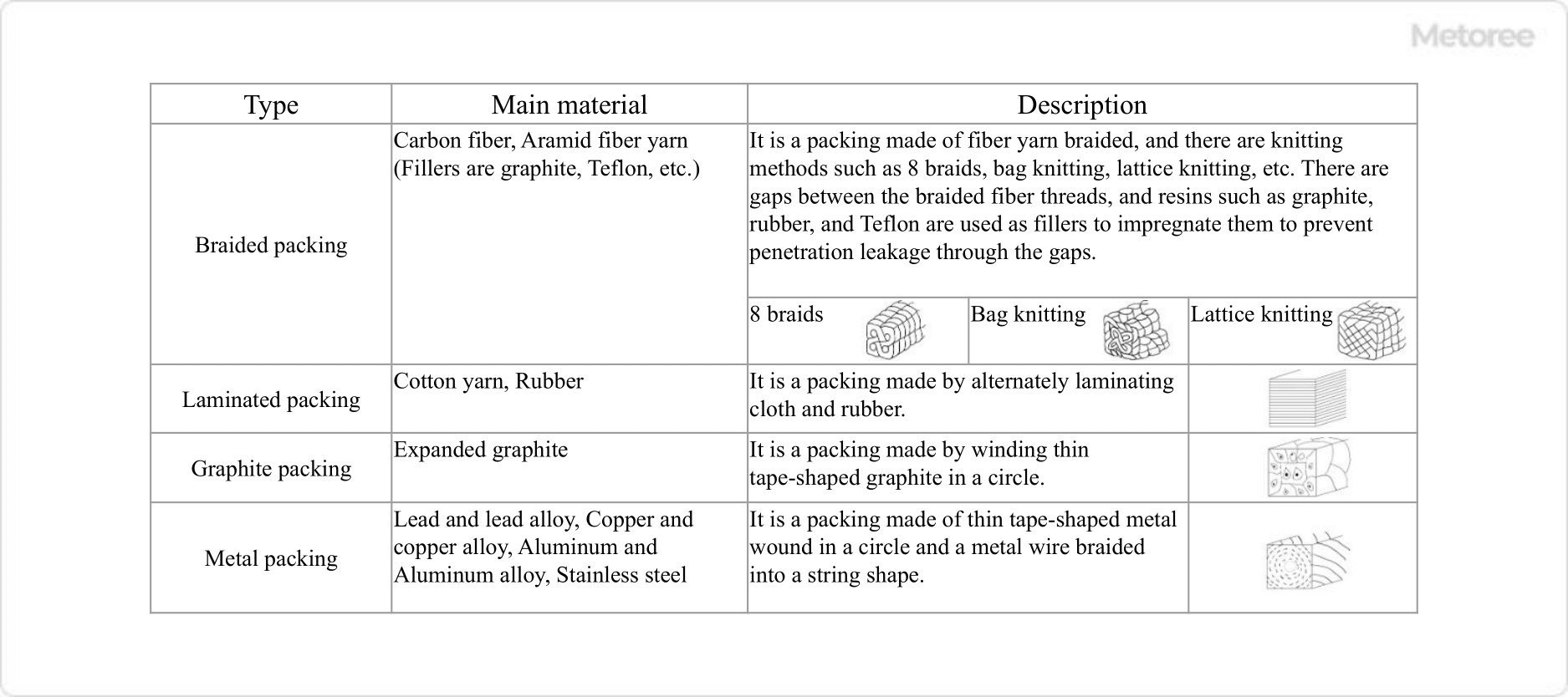

Types of Gland Packing

Figure 3. Types and main materials of gland packings

Gland packing is characterized by its relatively low cost as a shaft seal and simple structure compared with mechanical seals. Since each type has its own characteristics and the method of use and environment of use differ, it is important to check the manufacturer’s catalog, specifications, and instruction manuals before making a selection.

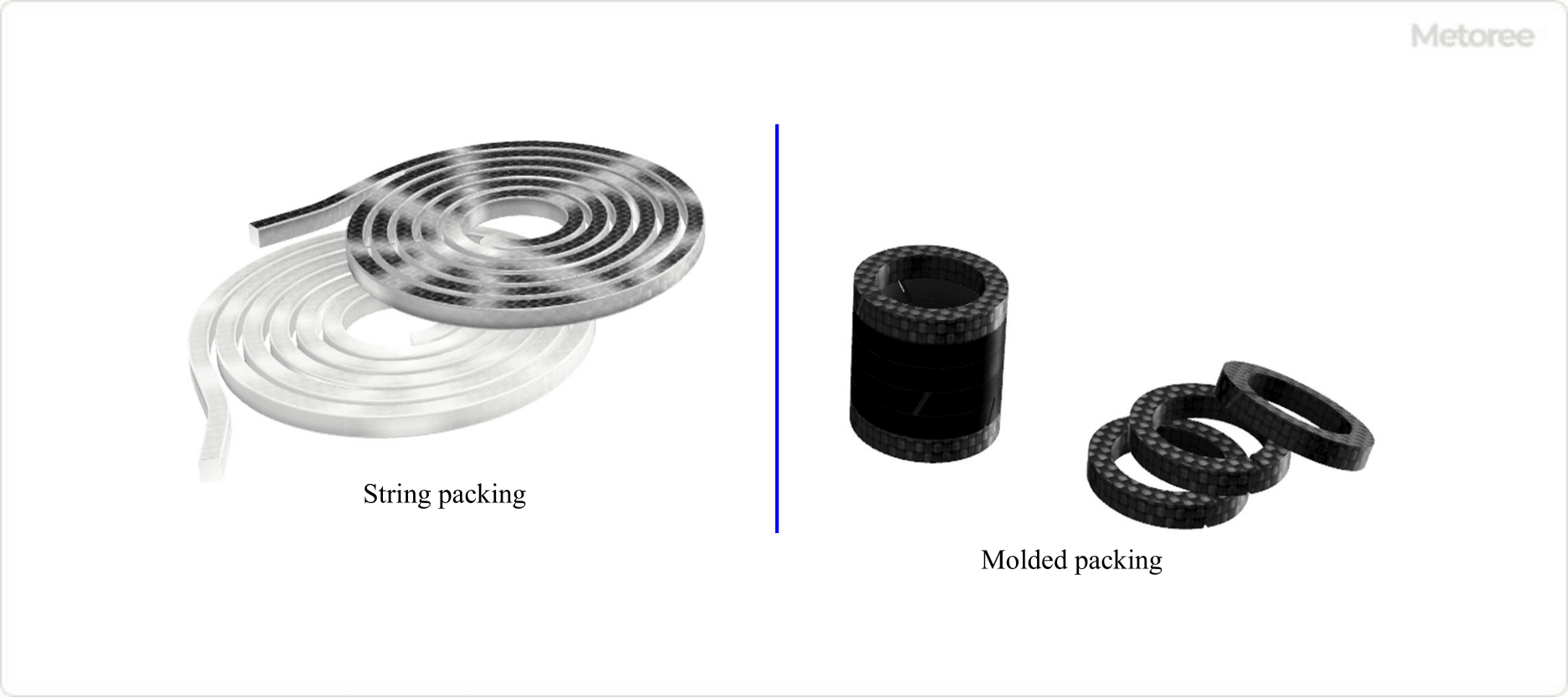

Figure 4. Types of gland packing

Gland packing (other than laminated packing) that is generally available on the market comes in a spiral wound form. Therefore, cut the packing to the required length according to the dimensions of the shaft and stuffing box, and insert it into the box. In addition to cutting and using the string packing, we can also produce a pre-molded ring-shaped packing to match the dimensions of the shaft and stuffing box.

The use of molded products improves the workability of packing insertion and sealing performance. In the past, asbestos packing (sealing material containing asbestos) was often used as a material for gland packing packings.

Other Information on Gland Packing

1. Number of Gland Packing Used

Normally, one gland packing is not used alone, but several gland packings (in layers) are stacked. Also, as shown in the figure above, using several seal rings (sealing packings) in combination with header rings (overflow prevention packings) will provide a more secure seal.

The number of gland packing (number of steps), packing material, and pressure of the fluid to be sealed vary, so refer to the packing manufacturer’s product specifications or instruction manuals to determine the appropriate combination.

2. Direction of Motion of Gland Packing and Shaft

The uses of gland packing include the following, depending on the direction of the shaft motion.

For Rotary Motion Axis

Figure 5. For rotary motion shaft of pump

It is mainly used for shaft sealing of pumps, blowers, and other shafts.

For Reciprocating Shaft

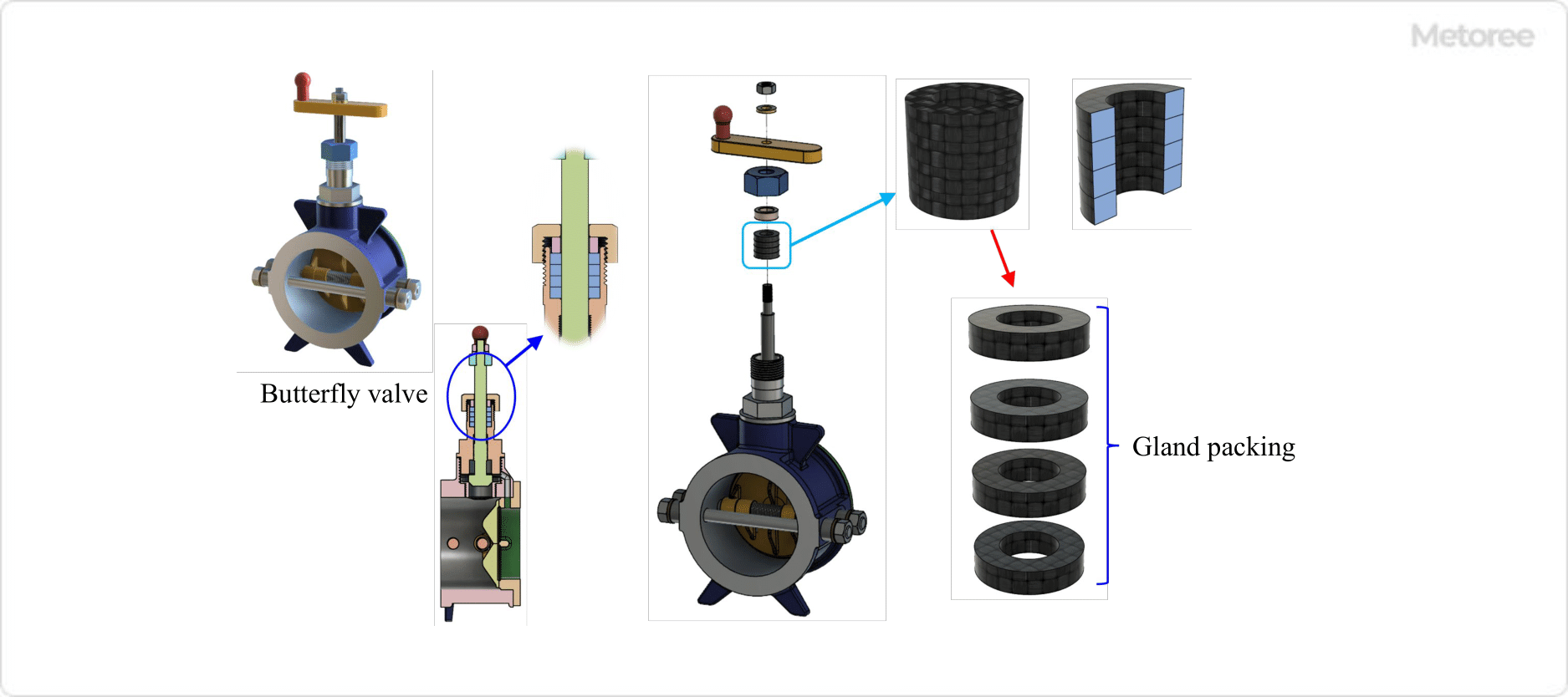

Figure 6. For reciprocating shaft of valve

They are used for shaft seals of valve stems (valve rods) such as valves.

In addition to the above, they are also used in the shaft seals of various rotating machines and machines with reciprocating shafts. They seal liquids, gases, powders, and other substances to ensure the normal operation of machinery and equipment.

3. Combination of Gland Packing

The gland packing for the pump consists of three rings of braided packing and a lantern ring. This lantern ring is used for the following purposes:

- Shaft cooling and lubrication

- Prevents wear by draining sand and other contaminants from the gland packing when they are mixed in with the fluid.

- Prevents air from being sucked in through gland packing when fluid pressure is below atmospheric pressure

Since gland packing causes some leakage, a shaft sealing device such as a mechanical seal is used when used to seal machinery, equipment, or hazardous materials with even less leakage.

4. Maintenance of Gland Packing

Gland packing may become worn and lose filler after long-term operation of the equipment, resulting in leakage. In such cases, the nut should be re-tightened or the gland packing should be replaced. Also, once a leakage path is created along the shaft, it is difficult to eliminate the leakage even by retightening, so replacement is also necessary in such cases.