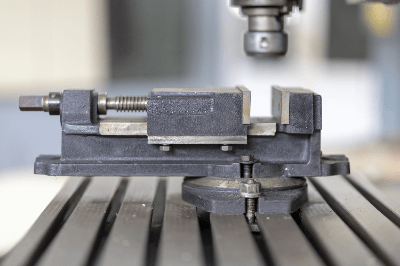

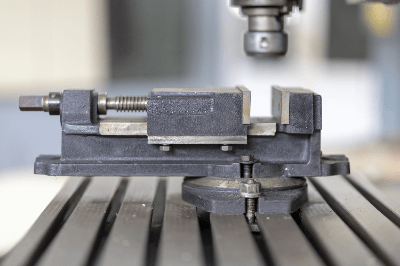

What Is a Milling Vise?

Milling Vise is a machining jig to fix a workpiece to a milling machine.

Milling means cutting process, and in Japan it is used to mean the same thing as milling machine. Milling Vise is a jig used for cutting process with a milling machine.

It has a handle and is designed to be durable, sturdy, and highly accurate. The vise part can rotate 360° in either direction. The high rigidity of the vise allows the workpiece to be secured with a strong clamping force even when strong force is applied, contributing to more efficient machining operations.

Applications of Milling Vises

Milling Vises are mainly installed on milling machines for rough machining of materials. There are various types. Precision vises are jigs with high accuracy in squareness and parallelism of each part.

The 2-D vise can freely adjust angles in two directions, while the 3-D vise can freely adjust angles in three directions.

In addition, there are some that can be fixed more firmly using hydraulic pressure and others that can be used for a variety of objects with a large opening of the mouth.

Principle of Milling Vise

Milling Vises are specialized for machines that perform cutting operations with milling machines. It has a main body and a movable part, and the movable part can be moved by a handle.

In cutting operations, the object to be machined is placed between the movable part of the Milling Vise and the main body, the movable part is moved by screws or handles to reduce the gap, and the object is secured by tightening the movable part strongly. The device not only strongly secures the object to be processed, but is also extremely durable.

This is because the Milling Vise is subjected to impact at the same time during the cutting process after the object is secured. They are designed to be strong and solid in every part against heat and shock.

Types of Milling Vises

The main types of Milling Vises are as follows

1. Precision Milling Vises

Each part is sturdy and durable, and these vises have high parallelism and squareness accuracy. Mounted on a milling machine, they are mainly used for rough machining. The object is fastened using a screw.

Vises with lift-off prevention function are available. The object is fastened not horizontally but in the direction of the lower base to securely fix it to the base and prevent it from lifting.

The upper vise part can be rotated 360° to the left and right. The super open type, which has a very large mouth opening, is also one of the precision Milling Vises.

2. hydraulic Milling Vises

Hydraulic Milling Vises use hydraulic pressure to push the mouthpiece. Strong tightening is possible even with light force. There are various types such as those with lift-off prevention function, those with a rotating stand, and super open type.

3. sign vice

Sign vises are vises that can be inclined to the base. The tilt angle is about 45°.

4. 2-D and 3-D Milling Vises

2D vises are equipped with a tilt angle function and a 360° rotating stand. They are used for complex cutting, polishing, and engraving processes, etc., as they can be freely set to the part to be machined.

The 3D vise is a 360° rotary stand with a stand that can be tilted up to 45° to the left and right, and up to 90° to the top and bottom.

How to Select a Milling Vise

1. size of the object

When selecting a vise, it is important to consider the size of the mouthpiece to be sandwiched between the object. Consider whether the mouth opening, mouth width, and mouth depth of the vise are suitable for the object.

If the width of the workpiece is larger than the width of the mouth, the overhang will cause chattering vibration, resulting in reduced machinability. If the height of the workpiece is much higher than the depth of the mouth, chattering vibration will occur at a point far from the mouth, resulting in a loss of machining accuracy.

2. Matching with the machine tool

The type of machine tool and the direction of machining can affect the accuracy of machining. For example, there are vertical and horizontal types of machine tools, and good results are obtained when the fixing direction of the vise is aligned with the machining direction of the machine.

Other Information on Milling Vises

Standards of Milling Vises

The accuracy of Milling Vises is specified in the TES2201 standard of the Japan Machine Tool Builders’ Association (JMTBA). The standard defines the parallelism and squareness of each part.