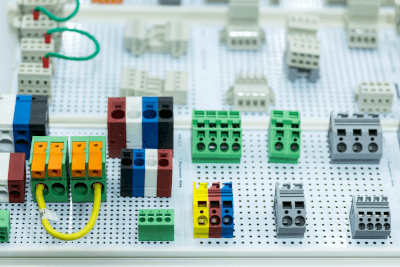

What Is a Relay Box With Terminal Blocks?

A relay box with terminal blocks is a wiring solution combining a relay box and terminal blocks, widely used in industrial and residential settings for effective electrical wiring management. These boxes help organize, protect, and facilitate easy connections and maintenance of electrical wiring systems, reducing the risk of electrical hazards and ensuring operational safety.

Applications of Relay Boxes With Terminal Blocks

These relay boxes are used in various industries for different purposes:

1. Industrial Control

In industrial control, they manage signal lines for sensors and motors, ensuring proper signal transmission in automated systems.

2. Construction and Housing

Used in residential and commercial buildings to manage electrical wiring for lighting and outlets, improving safety and appearance.

3. Telecommunications and Networks

Essential in telecommunications for organizing cable and fiber connection points, especially in data centers and network infrastructures.

4. Energy

Used in renewable energy systems to centralize power from sources like solar and wind, optimizing energy use and efficiency.

Principle of Relay Boxes With Terminal Blocks

These relay boxes are designed for effective wiring management:

1. Relay Box

Typically square-shaped, and made from materials like iron or plastic, these boxes feature a hinged front cover and are often sealed with rubber gaskets. They allow for organized wire routing and connections inside.

2. Terminal Block

Terminal blocks provide specific points for connecting electrical wires, facilitating organized and efficient wiring connections. They consist of metal plates and screw mechanisms for secure wire connections.

How to Select a Relay Box With Terminal Blocks

Consider these factors when choosing a relay box:

1. Number of Terminal Block Poles

Ensure the number of poles matches the required wiring connections. Consider future expansion when selecting the number of poles.

2. Applicable Wiring

Choose a box compatible with the wire thickness, voltage, and current requirements to ensure safe and efficient operation.

3. Enclosure Material

Select material based on the environment of use. Plastic is suitable for indoor use, while metal is necessary for outdoor or harsh conditions.

4. Rated Voltage

Choose a box with a voltage rating that matches the electrical system’s requirements, ensuring safety and component longevity.

5. Wiring Method

Select the appropriate wiring method, such as screw type, clamp type, or bus bar wiring, based on the wiring used and connection needs.

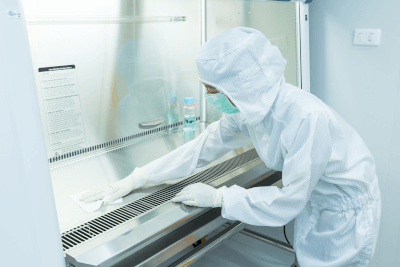

A board terminal block is a component designed for installation on a

A board terminal block is a component designed for installation on a

A collapsible crate, often with a mesh structure, resembles the

A collapsible crate, often with a mesh structure, resembles the