What Is Stainless Steel Machining?

Stainless steel machining involves machine processing of stainless steel, a material chosen for its corrosion and heat resistance. Despite its high hardness, which traditionally made it difficult to work with, advancements in machining processes have improved the ability to effectively machine stainless steel.

Stainless steel machining involves machine processing of stainless steel, a material chosen for its corrosion and heat resistance. Despite its high hardness, which traditionally made it difficult to work with, advancements in machining processes have improved the ability to effectively machine stainless steel.

The challenges of machining stainless steel have been addressed through a better understanding of the material’s properties, selection of suitable machining processes, and advancements in the various materials and machining equipment.

Uses of Stainless Steel Machining

Stainless steel machining is used in various fields due to the material’s superiority. It is used in products ranging from tableware and home appliances to construction materials and elevator interiors. The continual improvements in machining technology are expected to further expand its applications.

Types of Stainless Steel Machining

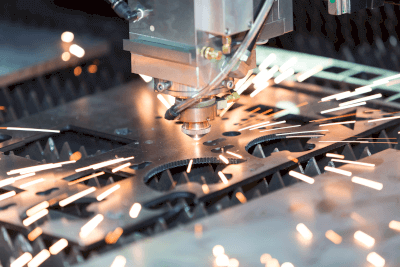

Various stainless steel machining methods have been developed to fully utilize the material’s characteristics. These methods are similar to those used in conventional metalworking but require innovations to accommodate the unique aspects of stainless steel. For instance, advanced technologies like laser processing are introduced for cutting, where the material’s hardness previously hindered workability.

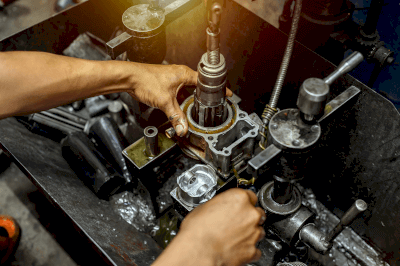

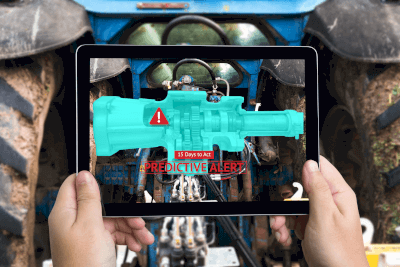

Advanced IT technology is also employed to predict and control springback in stainless steel machining. In welding, TIG welding is effective for thin sheets, but thicker sheets rely on the skill of technicians. Cutting stainless steel requires careful consideration of work hardening and distortion, depending heavily on the machinist’s expertise.

Various stainless steel surface treatment methods are employed, such as pickling, which removes impurities and enhances corrosion resistance, and black oxide processing which uses alkaline chemicals.