What Is a Metalworking Service?

Metalworking encompasses the processing of metal materials, including operations such as cutting, milling, and bending using various tools and machines. Another form of metalworking is casting, where nonferrous metal is poured into a mold, known as die casting, to achieve a specific shape.

Beyond these, metalworking also involves heat treatments like quenching, tempering, and annealing, as well as surface treatments such as plating. This field is distinct from other material processing types, such as stonework and woodworking.

Uses of Metalworking Services

Metal processing techniques vary depending on the material’s form. For example, metal sheets require cutting to size and bending with a press. Round bars of metal are shortened to the desired length on a lathe, then shaped through cutting processes, and threading may be added as needed. These semi-finished products, once shaped and bent, undergo surface treatments like heat treatment and plating before becoming finished products.

Principle of Metalworking Services

Metalworking operates on various scales, from large-scale projects such as bridges and ship fabrication to small-scale creations like jewelry. Each segment utilizes unique tools, skills, and processes. In modern automotive plants, rolled steel sheets are shaped under immense pressure by giant press machines in automated lines, while welding robots assemble automobile body parts. Conversely, in laboratories, precise metal parts are crafted by researchers using computerized, numerically controlled machine tools to cut aluminum blocks, automatically changing cutting bits as needed.

Types of Metalworking Services

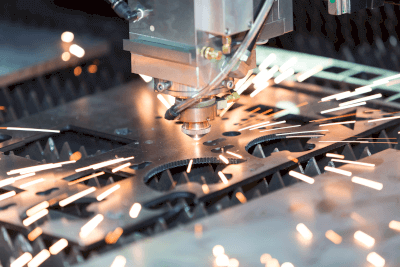

Metalworking is categorized into forming and property alteration. Forming methods include machining, plastic forming, casting, and others like welding, powder metallurgy, and metal 3D printing. Property alteration processes primarily involve heat treatment and surface treatment. Machining covers cutting (turning and milling), grinding, and special techniques (e.g., electrical discharge machining, laser machining).

Plastic forming methods comprise stamping, forging (both free and die forging), and rolling. Casting methods include sand casting and die casting, while heat treatments encompass quenching, tempering, normalizing, annealing, and carburizing. Surface treatments typically involve plating and conversion coatings, such as phosphate and chromate treatments.

How to Choose Metalworking Services

Selecting the appropriate metal fabrication method can significantly impact the cost and time required to produce parts with specific dimensions and characteristics. Understanding the advantages and limitations of each method is crucial. For instance, casting allows for rapid, mass production but may vary in dimensional accuracy. Conversely, pressing and cutting maintain high dimensional accuracy. The choice of process should consider the production schedule and delivery timelines. Material costs also influence overall expenses; materials widely available can reduce per-unit costs. However, choosing unsuitable materials for the product design might increase labor costs and production time. Although 3D printing offers efficiency, its initial costs are high.

Structure of Metalworking Services

Machine tools play a vital role in efficiently processing hard materials like metals. Primarily used in material removal processes, these tools include milling machines, drilling machines, and lathes. Machine tools not only produce parts for various equipment and machinery but also enable machining at speeds and precision levels challenging to achieve manually.