What Is an Honing Service?

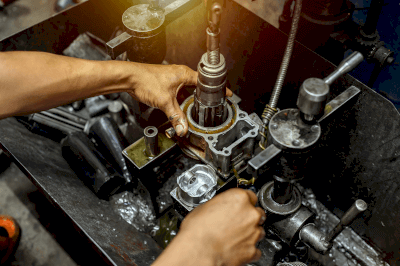

Honing is a process in which a grinding wheel is pressed against and rotated on the internal surface of a cylindrical part, with a significant amount of cutting oil applied. This method is similar to internal grinding, which also utilizes a grinding wheel to finish the internal surface of a workpiece.

However, honing allows for a larger contact area between the grinding wheel and the workpiece’s internal surface, achieving higher precision in terms of cylindricity, roundness, and surface roughness. As a result, honing is especially suitable for machining parts requiring high precision, such as automobile engine cylinders.

Uses of Honing Services

The inner surface of a honed workpiece features a fine mesh of stripes known as a “crosshatch.” These crosshatches function as lubrication grooves in engine cylinders, forming oil pools that reduce piston wear and resistance, thereby preventing seizure. Consequently, honing is frequently employed for parts involved in piston movement and is also used in machining gear tooth surfaces. The application of honing extends beyond the automotive industry, encompassing agricultural machinery parts, medical instrument parts, and various other fields.

Principle of Honing Services

Honing efficiently finishes the inside of holes. A magnet attached to the honing head secures it against the interior of the workpiece, and the surface is finished with a reciprocating, rotating motion. Honing achieves greater precision in drilling holes than internal polishing, maintaining the hole’s location while polishing, in contrast to internal polishing, which may shift depending on the centering method.

Types of Honing Services

Honing is performed using honing machines, which vary widely in shape, angle, orientation, and machining method. Besides general honing machines, there are three types of specialized honing machines: CNC multi-axis honing machines, parallel plane honing grinding machines, and liquid honing machines. These machines can hone internal surfaces as well as flat surfaces, external surfaces, and gears.

1. General Honing Machine

Uses radially mounted grinding wheels, called “horns,” rotating and moving reciprocally up and down along the axial direction to finish internal surfaces.

2. CNC Multi-Axis Honing Machine

Controls the position and speed via computer numerical control (CNC). Unlike in general honing processes where grinding wheels must be replaced at each stage from rough to final finishing, the CNC multi-axis honing machine automates the entire process.

3. Parallel Surface Honing Grinder

Enables specialized processing of flat surfaces. Two disk-shaped grinding wheels rotate back and forth for machining, allowing simultaneous processing of different shapes and multiple parts to the same height.

4. Liquid Honing Machine

Mixes abrasive grains with water to spray for processing. Suitable for matting, deburring, rust removal, and preparing painted surfaces for finishing. It can also handle complex shapes.

How to Select Honing Services

Honing is a high-precision method for finishing internal surfaces, utilizing a slow grinding process without significant pressure, making it suitable for heat-sensitive materials. The resulting cross-hatch pattern, achieved by controlling the grinding wheel’s rotation and vertical motion, can vary the cross-hatch angle from 20 to 60 degrees. However, honing cannot adjust to different hole diameters; the mandrel size is determined by the workpiece’s inner diameter. Pre-processing accuracy significantly impacts honing outcomes; if pre-processing is imprecise, internal grinding may be preferable, as honing cannot correct such inaccuracies.