What Is an Automatic Guided Vehicle (AGV)?

An automatic guided vehicle (AGV) is a cart-type robot that transports goods automatically and unmanned to their destination at factories.

Conventionally, forklifts and other equipment had to be operated by a person, but AGVs can automatically go to the destination, pick up the cargo, and transport it to the designated location. In addition to greatly improving the efficiency of transportation within a factory, this system also greatly reduces labor requirements, making a significant contribution to factory automation.

Since unmanned vehicles do not have operators, they are intended to transport goods such as luggage and are not allowed to be used on roads. In recent years, however, with the advancement of AI and data analysis technologies, an increasing number of AGVs are able to determine their own routes and travel autonomously without the use of magnetic tapes.

Uses of Unmanned Guided Vehicles

AGVs are mainly used at factories and other logistics sites to transport goods efficiently. The first AGVs were introduced around 1990, when magnetic tape was laid down on factory production lines to allow them to travel along a fixed route.

However, this method requires the removal and re-installation of a guideway if the route to be traveled needs to be changed. Although it is possible to change the route, large-scale construction work is required each time.

In recent years, however, autonomous automatic guided vehicles (AGVs) have been gaining popularity because they can set their routes based on image recognition using lasers and cameras, and they do not require a guideway made of magnetic tape. Depending on the product, AI may be able to make independent judgments to ensure that the route is lean and efficient in transporting goods.

Principle of AGVs

The reason that AGVs can reach their destination without human control is that the sensors installed in AGVs can read magnetic tape or magnetic markers that have been pre-installed on the factory floor, allowing them to trace the location accurately and route of the vehicle.

In terms of the principles of AGVs, they are classified into three main types. The characteristics of each are as follows:

1. Route-Guided Automatic Guided Vehicles

This is the most common type of AGV and uses the previously mentioned magnetic tape, magnetic markers, and other guidance devices to guide the vehicle along a specified route. This is the most widespread type of automatic guided vehicle to date, and it offers excellent cost performance due to the low price of the vehicle itself and the low threshold for its introduction.

However, it has the disadvantage that the travel route cannot be easily changed because the magnetic tape of the guideway is embedded in the floor.

2. Autonomous Mobile Rover

Also called an AMR (Autonomous Mobile Robot), this system transports goods while moving autonomously. With the development of AI technology, this type of vehicle has been rapidly introduced in recent years.

It uses lasers and cameras to measure the distance to surfaces, such as walls and pillars, to determine its own position. However, there is still room for improvement in terms of cost and environmental conditions that do not hinder unmanned vehicles, so the current state-of-the art is that they are being introduced mainly by large companies.

3. Tracking Type Unmanned Vehicles

This type of vehicle follows a person or vehicle ahead while maintaining a certain distance. As with the autonomous type, there is no need to install a guideway, but since the vehicle can only simply follow, the person or vehicle ahead must be controlled by a separate person.

Types of Unmanned Conveyance Vehicles

Various types of AGVs are available in a variety of cart shapes. Typical shapes are as follows:

1. Cart Type

The cart type is in the shape of a cart and carries cargo on its own.

2. Towing Type

The towing type does not directly load cargo on itself, but pulls cargo to the destination by towing a basket cart or pallet behind it. It can also pull multiple carts like a freight train.

3. Low-Floor Type

The low-floor type goes under the cargo, lifts the cargo up, and transports it to the destination. It can transport basket carts without wheels, pallets, and carts that are difficult to tow.

![Uninterruptible Power Supplies (UPS)]](https://metoree.com/wpdrs/wp-content/uploads/2023/01/Uninterruptible-Power-Supplies-UPS.png)

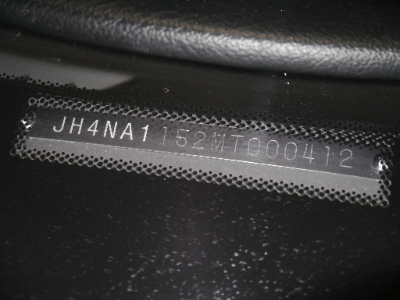

A nameplate is a metal nameplate on which the company name, product name, serial number, etc. are engraved, unevenly processed, and written on a

A nameplate is a metal nameplate on which the company name, product name, serial number, etc. are engraved, unevenly processed, and written on a