What Is a Tubular Furnace?

A tubular furnace is a long, cylindrical furnace, typically electric, with heating elements and heat-resistant materials around the internal tube. This structure enables uniform heating, precise temperature control, and adaptable temperature distribution. It’s efficient for direct heating and processing of materials within the tube and offers controlled flow and reaction management. However, design and operational mechanisms can vary significantly based on specific use and construction.

Applications of Tubular Furnaces

Tubular furnaces are used in various applications, including heat treatment, pilot production testing, and R&D. Specific uses include:

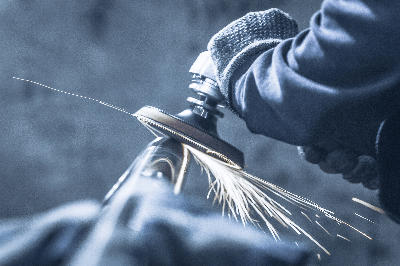

1. Heat Treatment Process

For heat treatment of metallic materials and ceramics, especially in quenching and tempering of steel materials, to alter microstructures and properties.

2. Research and Development

In R&D, they are used for the heat treatment of semiconductors, fuel cell material development, and catalyst development, especially in petroleum refining and petrochemicals.

3. Glass and Semiconductor Manufacturing

Used in glass manufacturing for melting raw materials and in semiconductor manufacturing for oxide film formation and annealing.

Principle of Tubular Furnace

A tubular furnace consists of a heating element, core tube, and heat-resistant materials:

1. Heating Element

Includes electric resistance heaters like nichrome, kanthal wire, or silicon carbide. Heaters are selected for durability and temperature characteristics, suitable for high operating temperatures.

2. Core Tube

A protective tube around the heating element, usually made from quartz or ceramic, and stainless steel for lower temperatures.

3. Heat-Resistant Materials

Includes materials like ceramic fibers, bricks, and coatings for insulation and heat retention in high-temperature environments.

Types of Tubular Furnaces

There are open and enclosed types of tubular furnaces, each suited for different applications:

1. Open/Closed Type

Open-ended furnaces allow easy material and gas access, suitable for experiments and research. They can be installed vertically or horizontally.

2. Sealed Type

Sealed tubular furnaces maintain controlled interior environments, ideal for high-precision heat treatment and reaction control in applications like semiconductor manufacturing.