What Is a Shredder?

Shredders are machines that crush objects by rotating rollers with blades. There are various types of shredders, ranging from small ones for shredding small amounts of rocks, wood, fruit, etc., for experiments to industrial ones for disposing of concrete and waste materials.

A similar type of machine is a crusher, but one that uses a reduction gear (gear) and is applied to objects larger than 20 mm is generally called a shredder. Reduction gears increase torque and enable shredders to crush large or hard objects. For this reason, shredders are sometimes used as a pretreatment for shredder.

Rotors made of stainless steel are rotated to crush objects as they are chewed to pieces, so the rotation speed of the rotor and the fineness of the blades are important. Initially, a trial operation should be made with coarse blades rotating at low speed, and the blades should be replaced with finer blades step by step while crushing a small amount of material and observing how the shredder performs.

Uses of Shredders

Shredders are mainly used to crush hard objects coarsely. If the material is to be ground down to powder form, it must be processed in a shredder after crushing.

Shredding materials used for extraction or reaction increases the surface area per volume, which increases extraction efficiency and reaction speed. Shredding is also effective for reducing storage space because of the reduced bulk. However, there are some disadvantages to shredding samples that are easily oxidized in air, such as the fact that shredding makes them more susceptible to oxidation. Judgment must be made according to the sample.

Principle of Shredders

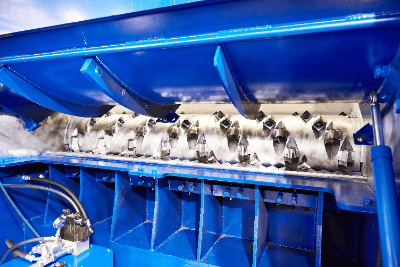

The basic structure of the shredder and its crushing mechanism are as follows:

1. The material to be shredded is put in through the feed port. To facilitate feeding, a hopper, which acts as a funnel, is attached to the feed port.

2. The inputted materials fall into the crushing chamber. In the shredding chamber, a rotor with blades like gears rotates and crushes the material as it is fed in. The rotation speed of the rotor and the fineness of the blades determine the crushing capacity. If the rotation speed is too fast, the fed material will be bounced off the rotor and will not be entrained. If the blades are too fine, they will clog and stop rotating. It is recommended to start with a trial run with coarse blades rotating at a low speed and optimize the rotation speed and blades by crushing a small amount of material at a time and observing how it goes.

3. The bottom of the shredding chamber is equipped with a screen, which acts as a “sieve.” The screen has holes of a certain size, and only pieces that are crushed finer than these holes pass through the screen and fall into the discharge outlet.

4. The shredded pieces coming out of the discharge outlet are collected in bags or batts.

Difference Between Single-Shaft and Twin-Shaft Shredders

Shredders are classified into “single-shaft” and “twin-shaft” types according to their shredding style. Each has its advantages and disadvantages, so knowing this classification will help you select the right model.

Single-shaft shredders have fixed blades lined up on both walls of the shredding chamber, and rotors drive between them. The material is pushed into the shredding chamber by an instrument called a pusher and is then caught by the rotor. The material is cut into small pieces by repeatedly passing between the rotor and fixed blades, and only those pieces that are smaller than the fineness of the screen are discharged. The advantage is that the shredder has high cutting power and can produce fine pieces, while the disadvantage is that the processing speed is slow.

The twin-shaft shredder has no fixed blades and two rotors installed in parallel. The material is fed into the shredder and is shredded by being caught between the two rotors. The advantage is the high processing speed, while the disadvantage is that fragments tend to be coarse and unevenly sized.

The single-axis type is recommended when the fineness of shredding is required, and the twin-shaft type is recommended when processing speed is required.

Wood Shredders

Some shredders are specialized for shredding wood. They are used to dispose of scrap wood and produce wood pellets, and a variety of models are available, ranging from small models for home use to large models for wood processing plants.

Small models for home use are primarily used to shred selected branches and small wooden furniture. They are sold under such names as “garden shredders” and “wood chippers,” and some models can be purchased inexpensively.

Some of the larger models for professional use are equipped with an engine and can run on caterpillars. When wood is piled up in multiple locations in a large workshop, efficiency can be improved by having the shredder move and work instead of carrying the wood.

One point to keep in mind when using shredders for wood is that the rotors are not strong enough. Because they are not designed for shredding rocks or concrete, accidentally feeding in rocks or other hard objects may cause the blades to spill, leading to malfunction.