What Is a Metal Tape?

Metal tape is a robust adhesive tape made from materials like lead, stainless steel, copper foil, aluminum foil, aluminum, magnets, or other metals. These tapes can be conductive or non-conductive and are often used in applications such as plumbing, water line repairs, and range hood ducts.

The functionality and adhesive strength of metal tapes vary with the material. For instance, aluminum foil tape can be laminated with glass fiber to increase strength, or it can be a heat-resistant type with silicone adhesive suitable for temperatures up to 300 °C. The selection of a metal tape should be based on its intended application.

Uses of Metal Tapes

Metal tapes have a wide range of uses in heat resistance, fire resistance, airtightness, waterproofing, fireproofing, soundproofing, electrical conductivity, heat conduction, and heat shielding. These applications extend across housing, construction, automotive, electrical, and electronic equipment sectors. They are used for:

- Sealing gaps in air-conditioning equipment, cooktops, and sinks.

- Waterproof repair of metal roofs and exterior walls.

- Repairing chimneys and bathtubs.

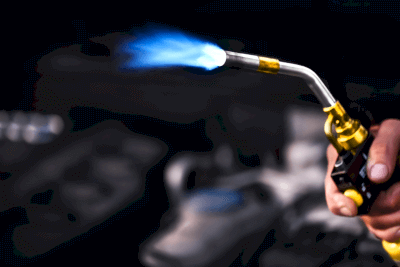

- Duct sealing in stoves and water heaters.

- Reinforcing engine compartments.

- Repairing tin roofs and corrugated sheets.

- Securing heat insulation tubes and glass wool.

- Heat dissipation for floor heating pipes, and more.

Characteristics of Metal Tapes

Different metal materials used in tapes have unique properties:

1. Aluminum Tape

Aluminum tape is sought after for its flexibility and temperature resistance. It comes in various forms, including aluminum-glass cloth tape, heat-resistant aluminum tape, and conductive aluminum tape.

Some tapes can be easily cut by hand, and conductive aluminum tapes with Ni powder are applied to the acrylic adhesive to discharge static electricity.

2. Copper Foil Tape

Copper foil tape is valued for its electrical and thermal conductivity, resistance to solvents, UV rays, humidity, and mold, and is used for electromagnetic wave shielding and fixing electrodes.

3. Stainless Steel Tape

Known for its rust and weather resistance, stainless steel tape is suitable for outdoor waterproofing and repair tasks.

4. Magnetic Tape

This flexible rubber magnet with adhesive is used in applications such as masking for painting steel products, including automobiles.