What Is a Spectrophotometer?

A spectrophotometer is a device that can connect to various wavelengths, irradiate spectral light onto a sample, and examine the wavelength and amount of light transmitted through and reflected from the sample. Spectrophotometers are common, versatile analytical instruments used in various fields, including research and development, quality control, and chemical analysis.

Typical instruments include Vacuum Ultraviolet Spectrophotometers (VUV), Ultraviolet-Visible Spectrophotometers (UV-Vis), and Infrared Spectrophotometers (IR), each capable of obtaining different information by using light in distinct wavelength ranges.

Uses of Spectrophotometers

Spectrophotometers Are Used in Design, Color, Paint, and Other Color-Related Industries

Spectrophotometers are used in various industries that rely on color-related measurements. For instance, in the automotive industry, spectrophotometers are employed to inspect the quality of car bodies after coating, as the design and color of cars are crucial.

In the paint industry, spectrophotometers are used to assess the color quality of paints to ensure they achieve the desired color.

Spectrophotometers Are Also Used for Quality Control

Other industries, such as the food and design sectors, where product appearance is critical, utilize spectrophotometers for color evaluation as part of their quality control processes.

Principle of Spectrophotometers

Spectrophotometers detect the light transmitted or reflected from a sample and generate a corresponding spectrum. Analyzing these spectra provides various information about the sample, such as quantitative analysis based on peak intensities, qualitative analysis from spectral waveforms, and evaluations of electronic states, molecular structures, and material properties.

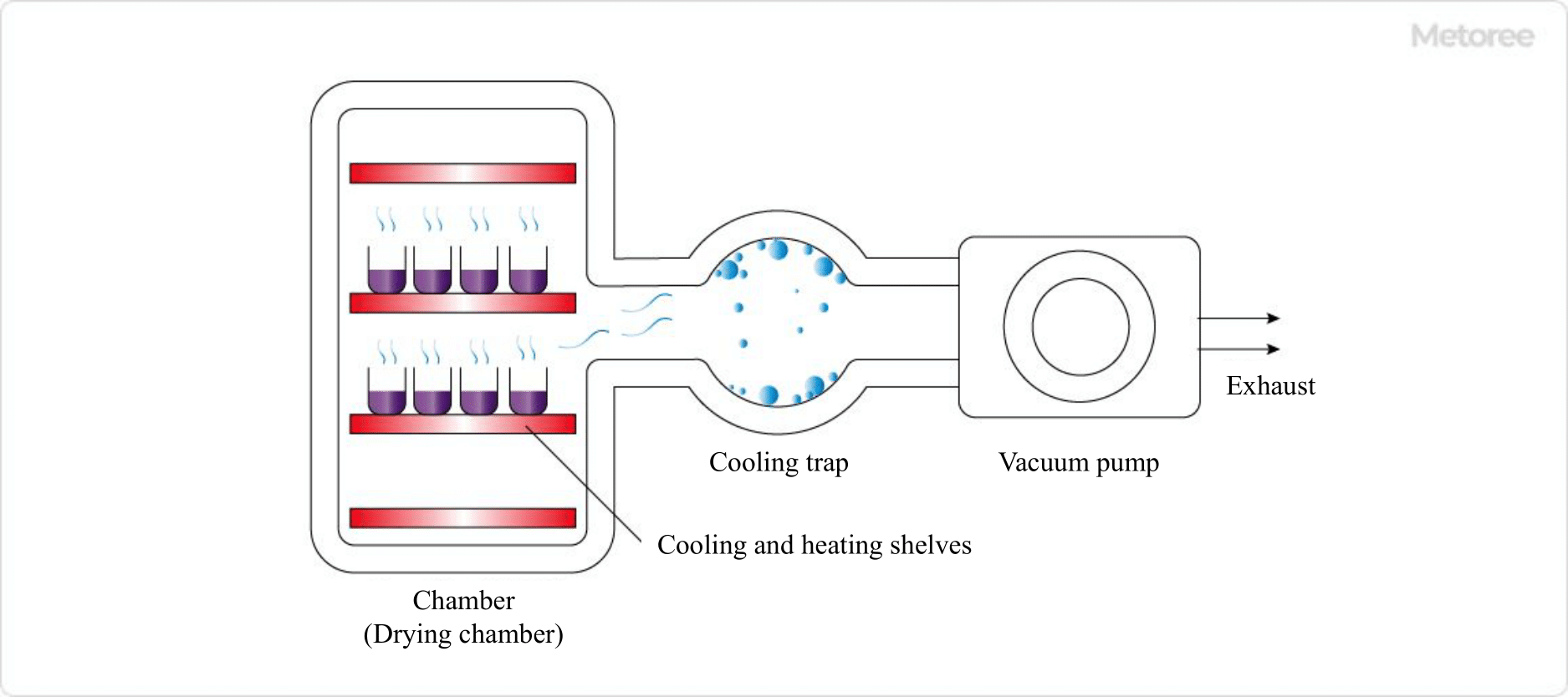

The instrument primarily consists of a light source, a spectroscope section, a sample section, and a detector. The light source emits light for analysis, with deuterium discharge tubes used for the ultraviolet region and tungsten lamps for the visible and near-infrared regions being the two primary light sources.

The spectroscope selects specific wavelengths of light from the light source and is available in filter, prism, and diffraction grating types.

The sample section contains a cell that holds the sample to be measured, primarily made of glass or quartz.

The detector converts the light transmitted from the sample into an electrical signal.

Types of Spectrophotometers

Spectrophotometers irradiate a sample with light to examine the wavelength and absorption of the transmitted and reflected light. Several types of instruments are available, depending on the light source. This section provides an overview of three types of spectrophotometers: Vacuum UV Spectrophotometer, UV-Visible Spectrophotometer, and Infrared Spectrophotometer.

1. Vacuum Ultraviolet Spectrophotometer (VUV)

The vacuum ultraviolet spectrophotometer uses light in the vacuum ultraviolet region (200 nm or less) as a light source to examine light transmitted through or reflected from a material. Since light in the vacuum ultraviolet region is absorbed by oxygen and nitrogen molecules, measurements must be conducted in a vacuum. This type of spectrophotometer is used to evaluate material properties.

2. UV-Visible Spectrophotometer (UV-Vis)

This device uses ultraviolet light (200-380 nm) and visible light (380-780 nm) as light sources to examine light transmitted through and reflected from a material. It allows for qualitative and quantitative analysis of sample components.

3. Infrared Spectrophotometer (IR)

Two types of IR spectrophotometers exist: near-infrared (780-2500 nm) and mid-infrared (2500-25000 nm). These spectrophotometers can estimate molecular bonds, and functional groups, and perform quantitative analysis of sample components.

Special spectrophotometers include the Raman spectrometer, which detects Raman light scattered from a sample to identify molecular structures and evaluate material properties, and the Fourier Transform Infrared Spectrophotometer (FTIS), which uses an interferometer to simultaneously detect non-dispersive light at all wavelengths and perform Fourier transformation to calculate components at each wavelength. Fourier Transform Infrared Spectroscopy (FT-IR) is also available.

Other Information on Spectrophotometers

1. Single Beam and Double Beam

The optics of spectrophotometers vary widely based on their purpose. As an example, we will discuss single-beam and double-beam systems.

Single-beam (monochromatic) optics refer to an optical system in which monochromatic light (light of a single wavelength) spectrally illuminated by a monochromator is directed onto a sample, and the reflected or transmitted light is detected by a detector. While single-beam systems have a simple optical configuration and are relatively cost-effective, they may not be suitable for highly accurate measurements due to larger measurement errors.

The double-beam method improves on these disadvantages. In the double-beam method, the light spectra from the monochromator are divided into sample light and reference light by a half-mirror or similar component. The sample light illuminates the sample, and the reflected or transmitted light is detected by a detector, similar to the single-beam method.

Since both the reference light and sample light contain errors attributed to the instrument, the signal from the reference light is processed alongside the signal from the sample light to cancel out these effects.

2. Difference Between a Spectrophotometer and a Colorimeter

Colorimeters are used for various purposes, but here we will discuss two typical types: colorimeters (color difference meters) and spectrophotometers.

- Colorimeter (Color Difference Meter)

A colorimeter is based on the direct reading method of stimulus values. When the human eye perceives colors, it receives stimuli from sensors (cones) in the retina and reads the three stimulus values of red (X), green (Y), and blue (Z). Colorimeters directly measure these three stimulus values using physical filters with response characteristics equivalent to human visual angle characteristics. They are widely used in production and manufacturing to assess color differences from the actual product (color sample).

- Spectrophotometer

A spectrophotometer, also known as a colorimeter, is a colorimeter based on the spectrophotometric method and is a type of photometer that measures the intensity of light. Reflecting light from the object is broken down into a spectrum for each wavelength by a spectral sensor and measured. Tri-stimulus values are calculated from this spectral characteristic. By defining spectral characteristics (spectral values) as color reference values, highly accurate color management can be performed with digital values even without actual samples. Due to challenges in managing actual samples (color samples) like variation and deterioration over time, color management using a spectrophotometer as a reference color (digital value) has become the mainstream method.

3. Daily Maintenance Guidelines for Spectrophotometers

One of the issues that can disrupt measuring instruments is maintaining and ensuring their accuracy. Spectrophotometers are no exception. It is essential to perform daily inspections as it is too late to take countermeasures after a failure has occurred.

Here are some important indicators for spectrophotometers that should be checked daily to detect abnormalities early:

- Wavelength Accuracy: This refers to the error between the wavelength detected by the device and the light source wavelength.

- Wavelength Repeatability: Wavelength repeatability measures the variation in wavelength when the same wavelength is measured repeatedly.

- Resolution: Resolution evaluates the bandwidth when measuring monochromatic light and is typically managed by Full Width at Half Maximum (FWHM).

- Stray Light: Stray light refers to light, other than the target wavelength, obtained from the device.

A phase contrast microscope is a type of

A phase contrast microscope is a type of