What Is a High Voltage Power Supply Unit?

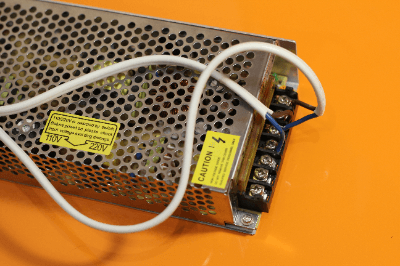

A high-voltage power supply unit is a power supply unit that handles particularly high voltages.

A high-voltage power supply unit is a power supply unit that handles particularly high voltages.

High voltage generally refers to voltages ranging from several thousand volts (V = volts: a unit of voltage) to several tens of thousands of V or higher. The voltage transmitted by power companies is 6.6 kV or higher, but high voltage is generally defined as 600 V AC (750 V DC) or higher.

The electrical appliances we use in our daily lives have low voltages of 100 VAC or 200 VAC. This is due to the fact that the standard power supply voltage transmitted from the power company’s generation facilities to each household is either 100 VAC or 200 VAC.

Although typical power supply units are 100 VAC or 200 VAC, some equipment may want to generate higher voltages depending on the conditions of use. Specifically, these are devices that require higher voltages than the power supply voltage or devices to be tested for tolerance to high voltages. In order to clear this requirement, a transducer that generates higher voltage than the power supply voltage used by general users is needed. High-voltage power supply units are used in such cases.

Uses of Applications of High Voltage Power Supply Units

High-voltage power supply units are mainly used for operating products that require high voltages and to withstand voltage testing.

Examples of equipment that require high voltage include equipment used for painting automobile bodies and construction materials, equipment used for surface treatment of metals and plastics, X-ray radiation equipment used for radiation therapy and x-rays, and electron microscopes.

Pressure resistance testing is performed on industrial electrical equipment such as electric wires. Products are often tested to withstand voltages of 1500 V for 1 minute or 1800 V for 1 second before shipment, and that insulation withstand voltages be tested. Therefore, the introduction of high-voltage power supply units is mandatory. They are also used for practical training to acquire qualifications as high voltage and special high voltage electricity handlers.

Principle of High Voltage Power Supply Units

High-voltage power supply units are converters that input general AC power transmitted to the end of the line and output it as high-voltage. A converter is a device (unit) that converts the AC power supply voltage transmitted from the power company into DC voltage using a circuit with diodes called a rectifier and smoothes the voltage with an electrolytic capacitor.

However, simply using a converter unit will only output a DC voltage that is smoothed at a low voltage because it is 100V or 200V, and will not provide the high voltage of 10 times or 100 times or more the voltage originally desired. It is possible to boost the voltage simply by the turn ratio of the step-up transformer, but the turn ratio has a practical limit.

To obtain a high voltage, a Cockcroft-Walton circuit combining a diode and a capacitor is used. This method uses the storage capacity of the capacitor and the rectifying action of the diode. After the capacitor stores electricity in response to an AC input in one direction, the voltage is boosted when a current flows in the opposite direction.

This circuit method is commonly used to raise the voltage by layering the rectifier-based circuit described earlier and is also referred to as a doubling voltage circuit or a high-voltage generator circuit among technical personnel. Since the voltage increase is an even multiplication, it is not possible to boost the voltage by an odd number of times. High voltages of 1 kV or higher can be obtained by combining an appropriate high voltage diode and ceramic capacitor.

Other Information on High Voltage Power Supply Units

1. High Voltage Power Supply Module

High-voltage power supply modules are high-voltage compatible power supply units capable of supplying high voltages that generally generate 1 kV or more.

Among these, power supply unit manufacturers with an established reputation for their technological expertise in downsizing through higher efficiency while ensuring low noise and reliability have achieved low prices by improving the quantity and ease of use of their products, and have modularized their high-voltage output power supply modules as general-purpose products.

Major manufacturers and products of high-voltage power supply modules include the OHV series by Bellnix, the TCR series by American High Voltage; the HGP series by Matsusada Precision, HitekPower by General Products; the TMK series by Takasago Machinery Works, the C14051 series by Hamamatsu Photonics, etc. The more the output current increases in addition to the original high voltage, the larger the size of the module becomes. Therefore, it is necessary to select a module with attention to its margin, temperature rise, and dielectric strength depending on the actual use of the load.

2. High-Voltage Power Supply Board

The substrate of a high-voltage power supply is a high-voltage circuit, so there are some precautions that must be taken for the substrate used in the high-voltage circuit. This is because the higher the voltage, the more the standard requires that the insulation distance of the board be sufficiently secured. The higher the voltage is, the greater the possibility of serious electric shock during work. To ensure safety, safety measures against withstand voltage and electric shock must be taken, including the creepage distance and insulation distance of the circuit board and the installation of safety grounding.

In practice, the IEC standard absolutely requires a board pattern design that ensures insulation distances between conductive copper foil patterns on the board based on each country’s standards. Failure to comply with this requirement may result in fines or other penalties as a violation of the law, and not only penalties, but also a loss of social credibility. Therefore, both the manufacturer and the user must be very careful to ensure that the insulation distance of the board pattern meets the standard.