What Is an Automotive Connector?

Automotive connectors are components used exclusively in automobiles to connect automotive wiring.

Automotive connectors are components used exclusively in automobiles to connect automotive wiring.

As automobiles become more sophisticated with advanced communication functions and higher performance, the number of electronic circuits and components increases, and many types of in-vehicle connectors are being developed. In addition, electric vehicles are now being sold, and special connectors are being used for charging and discharging.

There are many types of in-vehicle connectors that can be adapted to the sensors and environments of humidity, temperature, vibration, and water installed in automobiles. There is a lineup from minute signals in the wiring to be connected to high power applications.

Uses of Automotive Connectors

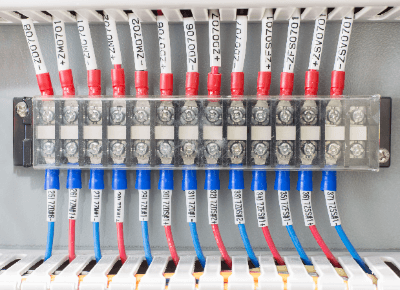

Since connectors used for wiring in automobiles in general are called automotive connectors, there are many types of connectors, including harness connectors, FPC connectors, board-to-board connectors, and coaxial connectors. The intended use differs depending on the type.

- Harness Connectors

Safety systems, high voltage, waterproof, advanced driving systems, etc.

- FPC Connectors

Advanced driving systems, multimedia

- Board-To-Board Connectors

Advanced driving systems, ECUs

- Coaxial Connectors

Advanced driving systems, multimedia, ECUs

Principles of Automotive Connectors

Since automotive connectors serve to connect wires together, their structure is basically the same as that of general connectors. Connectors are divided into two main parts. The contacts, which electrically connect the wires to each other, and the housing, which is an insulator that incorporates the contacts.

In the case of automotive connectors, many connectors are equipped with a mechanical lock to prevent poor contact or disconnection due to vibration. When the plug is pushed in, a clicking sound is heard, and the connector is securely locked. Other connectors have a structure that allows secondary engagement with a housing lance and retainer to prevent the contact part from falling out.

In addition, products with materials and structures suitable for the environment of the location where in-vehicle connectors are used are used. For example, connectors for charging and discharging electric vehicles are designed to provide adequate waterproof protection, and the outer plastic of such connectors is made of a weather-resistant and strong enough plastic to prevent deterioration and impact damage.

Other Information on Automotive Connectors

Applications of Automotive Connectors

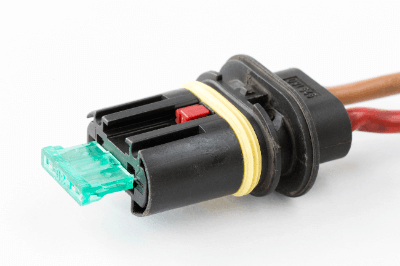

1. Automotive Waterproof Connectors

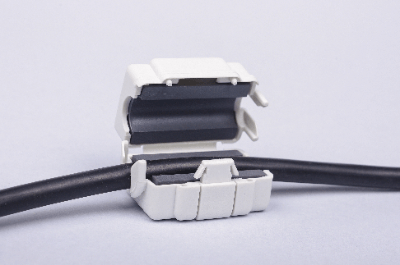

Waterproof connectors are used in places where waterproofing or dustproofing is required. Specifically, they are used around the engine compartment where water and oil are generated, around floor mats where water from wet shoes can seep in, and in places where water may enter during rainy weather. Compared to ordinary connectors, the structure is significantly different, and waterproofing measures range from external measures as water-repellent treatment of the case to a single terminal inside the connector.

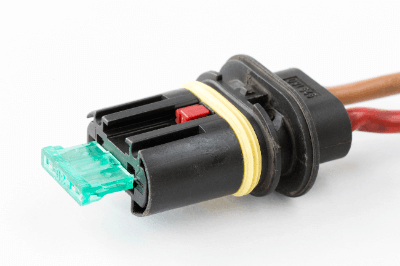

A seal ring is used on the terminal inside the connector to fill the gap that occurs during mating, preventing water, oil, and dust from entering from the outside. In addition, the part where the wire connects to the terminal is fitted with a rubber plug that is tightened to provide environmental resistance as well as resistance to external forces, such as pulling.

Connectors used around engines have a structure that can withstand high temperatures and vibration in addition to waterproofing. Due to their complex structure and high environmental resistance, automotive waterproof connectors are much more expensive to produce than normal automotive connectors, with a difference of several, to dozens of times the cost.

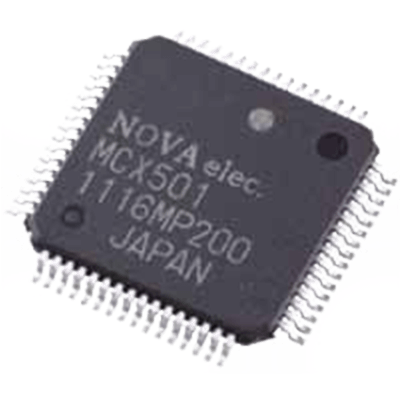

2. Automotive Connectors for Safety Components

Automotive connectors are sometimes used for components that require strict management from a safety standpoint, such as airbags, collision detection sensors, and ECUs (electronic control units). Since airbags directly affect human lives, high reliability is required, and in addition to waterproofing, measures are taken to prevent under-insertion and un-mating when mating connectors.

A double mating structure with two parts, a retainer and a front cap, prevents unmating. The retainer and front cap cannot be installed unless the connector is securely mated. This prevents insufficient insertion during mating.

In addition, measures are also taken to prevent incorrect mating by the operator during the assembly process. The shape and color of the connector are significantly different from those of standard connectors, making it possible to identify errors at a glance. The color of connectors used for airbags, an important safety component, tends to be yellow.

3. Onboard Connectors Used for High-Voltage Components

Connectors such as those used for charging and discharging electric vehicles require high voltages to shorten the time required for charging and discharging. When used for high-voltage components, they require higher safety performance than ordinary connectors, including measures to prevent electric shock and ignition due to a rise in the generated temperature.

In addition, since it is assumed that consumers will be able to charge the batteries themselves, robustness and light weight are required. Standards have been established to ensure that these safety features do not vary, and by complying with the standards, connectors from any manufacturer can be used, as long as they are compatible across manufacturers as long as they comply with the same standards.

4. In-Vehicle Connectors for Use in Advanced Driving Systems

In-vehicle connectors used for advanced driving systems need to be able to monitor the location of surrounding vehicles, people, motorcycles, and other objects while moving, so they must have high-speed communication performance to prevent communication loss.

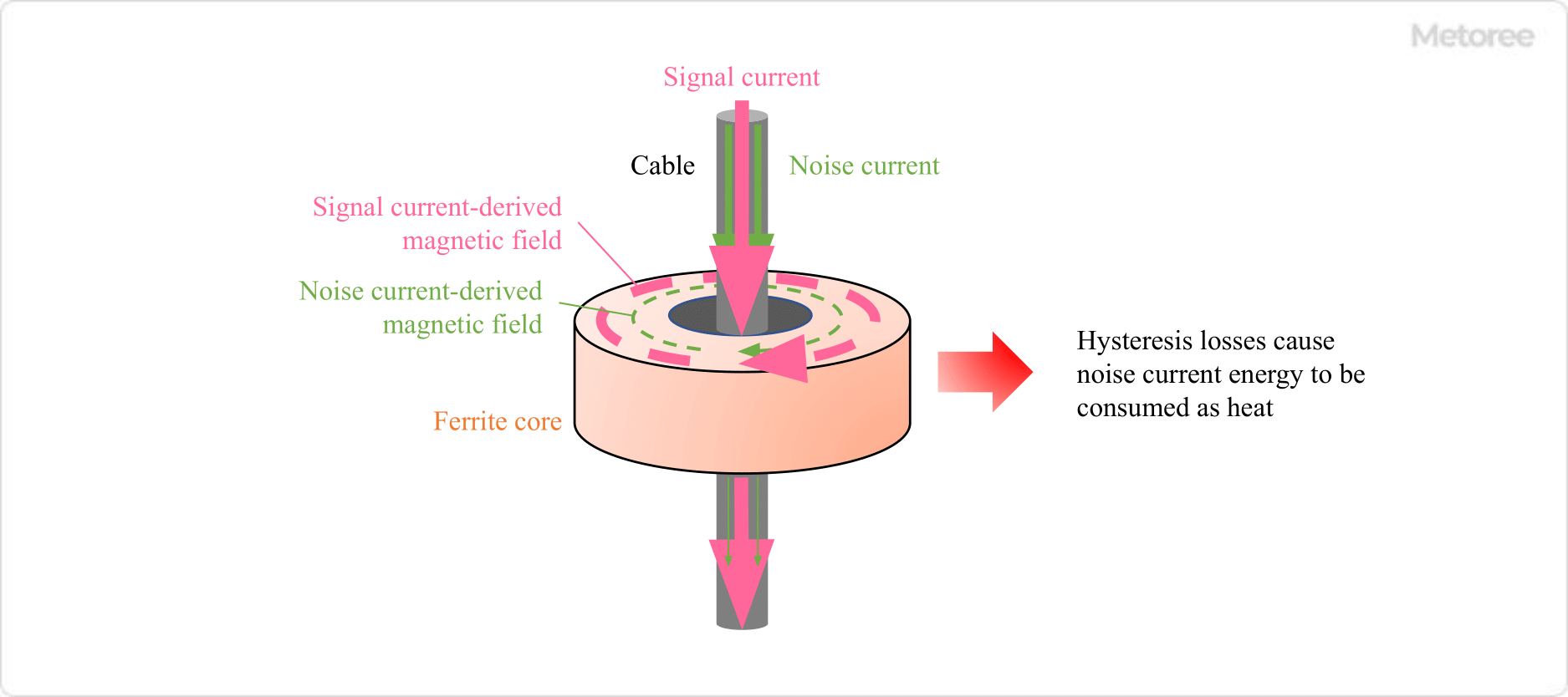

In addition, many types of communication can take place in a car, such as smart phone signals, TV reception, etc. Therefore, noise immunity performance is required to prevent malfunctions caused by these communications and to prevent malfunctions in the surrounding communications. To improve high-speed communication performance and noise immunity, shielded components are indispensable to protect signal lines.

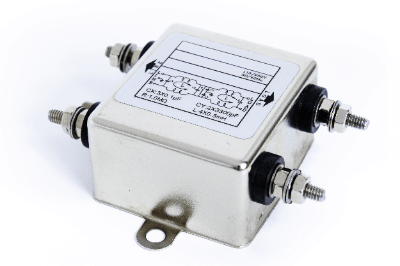

A noise filter is an electronic component used to remove noise from a power supply or signal.

A noise filter is an electronic component used to remove noise from a power supply or signal.

A heater is a general term for any device that generates heat.

A heater is a general term for any device that generates heat.

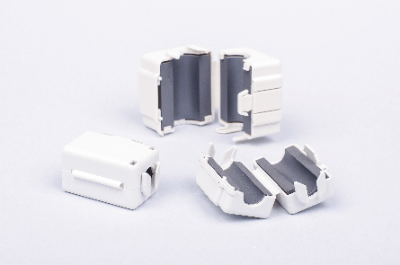

A ferrite core is a ceramic

A ferrite core is a ceramic

Automotive connectors are components used exclusively in automobiles to connect automotive wiring.

Automotive connectors are components used exclusively in automobiles to connect automotive wiring.