What Is a Rotating Shaft?

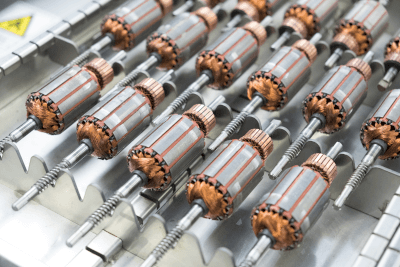

A rotating shaft is a mechanical element that rotates, typically to transmit power from a motor to other parts like pulleys and gears.

A rotating shaft is a mechanical element that rotates, typically to transmit power from a motor to other parts like pulleys and gears.

This article will focus on the rotating shaft as a power transmission component and its role in various types of equipment, including robots.

Uses of Rotating Shafts

Rotating shafts are categorized into drive shafts and driven shafts, each with distinct functions:

1. Drive Shaft

- Used to transmit motor power to the agitator blades or pump impellers.

- Converts rotary motion to linear motion, as in the case of a ball screw.

2. Driven Shaft

- Supports gears or pulleys, as seen in robot wrists or geared motors.

- Transmits power from drive shafts to remote parts using transmission elements.

Principle of Rotating Shafts

Rotating shafts are designed to transmit engine or motor power through rotation. They use gears to vary rotational speed, pulleys for power transmission by friction, and fans for moving air along the shaft. Typically, these shafts are supported by bearings at both ends.

Types of Rotating Shafts

Shafts are classified as drive shafts, connected to the power source, or driven shafts, which transfer power to other components.

Performance and Cost Considerations

Key Factors

- Material: Determines strength and corrosion resistance.

- Tolerance: Important for fitting, dimensional accuracy, and geometric tolerance.

- Additional machining: For fixing rotating elements.

- Surface treatment: To enhance strength and corrosion resistance.

Common Materials and Treatments

- “S45C” and “SAE 304” are typical materials, chosen for cost-effectiveness and rust resistance.

- Surface treatments like iron tetroxide coating, electroless nickel plating, and high-frequency quenching are used to improve durability and functionality.