What Is a Lathe Bit?

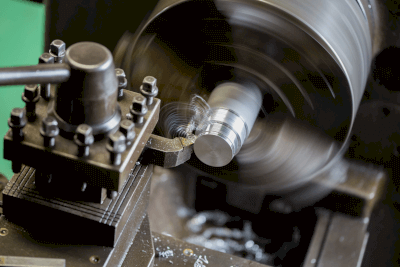

A lathe bit, or brazed bit, is a tool used in lathe turning, notable for its cutting-edge brazed to the body.

A lathe bit, or brazed bit, is a tool used in lathe turning, notable for its cutting-edge brazed to the body.

Unlike disposable bits with separate blades and bodies, lathe bits feature a one-piece construction. Before use, they require shaping by sharpening the cutting edge, typically with a grinder or tool grinder. The blade can be customized to various machining conditions and reshaped after wear.

Usage of Lathe Bit

Lathe bits are cutting tools employed in metal turning. Their diverse shapes cater to specific needs:

- General turning tools

- Single-edge turning tools (Right/Left)

- Horizontal sword turning tools (Right/Left)

- Sword turning tools (Right/Left)

- Heel finishing tools

- Butt cutting tools

- Round hole drilling tools

- Rough hole drilling tools

- Hole finishing tools

- Threading tools (Standard/Female/Heel)

- Flat cutting tools

- Serious cutting tools for flat-cutting machines

- Flat grinding machine tools

- Right single-edge cutting tools for flat-cutting machines

- Left single-edge cutting tools for flat-cutting machines

- Right sword-cutting tools for flat-cutting machines

- Left sword-cutting tools for flat-cutting machines

- Flat sword-cutting tools for flat-cutting machines

- Heel finishing tools for flat-cutting machines

- Butt-cutting tools for flat-cutting machines

Each shape is tailored for specific operations and machinery types.

Principle of Lathe Bit

Lathe bits are differentiated as right-hand or left-hand types based on the blade’s position. This distinction is crucial for aligning with the machining direction and the setup of the machine.

During operation, the workpiece is rotated against the lathe bit. The bit’s shape is adjusted according to machining conditions, chip disposal, and blade longevity.

Lathe bits, suited for heavy-duty cuts, need periodic sharpening. Conversely, disposable bits, ideal for fine machining, are ready for use after the insert is placed in the holder.