What Is a Diffraction Grating?

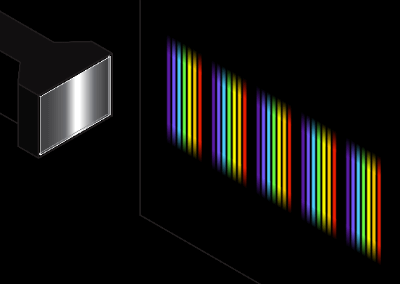

A diffraction grating is an optical element fabricated on a glass substrate with finely spaced grooves at equal intervals. When light is irradiated onto a diffraction grating, the effect of the grooves causes a diffraction of light, which allows the incident light to be divided according to its wavelength. Types include transmissive, reflective, and brazed types. Each has a slightly different structure, and therefore, different spectral performance.

Since diffraction gratings can extract light of a certain wavelength, they are used in monochromators, which emit light of a single wavelength, and polychromators, which emit light of a fixed wavelength range.

Uses of Diffraction Gratings

Diffraction gratings have fine grooves on their surfaces, and they have the property of dividing incident light spectrally into different wavelengths. The gratings are used in devices that use this property to control the wavelength of light.

For example, they are used in monochromators that emit light at a single wavelength and polychromators that emit light at a fixed wavelength. They are also used in spectrophotometers for astronomical observations, various spectroscopic analyzers in the natural sciences, and manufacturing and quality control equipment for pharmaceuticals and chemicals.

Principle of Diffraction Gratings

Diffraction gratings are made by vapor-depositing a metal such as aluminum on a glass substrate and engraving a large number of parallel lines (15,000 to 30,000 for UV to visible light and 1,500 to 2,500 for infrared light). These grooves scatter the incident light, resulting in interference fringes. As a result, the incident light can be spectrally split according to wavelength.

Compared to prisms, diffraction gratings are used in many spectrometers because of their superior light resolution and equal dispersion at all wavelengths. Prisms are made from optical glass and disperse light using different refractive indices for each wavelength of light. Diffraction gratings use the fact that the diffraction direction of the incident light diffracts in different directions, depending on the wavelength of the light to disperse it.

The basic principle of diffraction gratings is illustrated in the figure below. Diffraction gratings use the diffraction phenomenon of light. Light incident on a microscopic slit S0 diffracts in various directions, with S0 as the wave source. Diffraction gratings have grooves or other structures (S1, S2, …, G1, G2, …) corresponding to these slits, or G1, G2,…) at equal intervals (in a grating). Light emitted or reflected from the grooves causes interference. The light emitted or reflected from the grooves causes interference. Interfering light in the angular direction of the emitted or reflected angle such that the optical path difference between adjacent grooves is an even multiple of a half wavelength (an integer multiple of the wavelength) strengthens each other while interfering light in the angular direction such that the optical path difference is an odd multiple of a half wavelength (a half integer multiple of the wavelength) weakens each other. Using this principle, light can be divided into wavelengths and extracted.

There are two types of diffraction gratings: original and replica. Original gratings are difficult and expensive to fabricate because they must be especially precise. Replica gratings can be manufactured in large numbers from original gratings and are therefore inexpensive and widely used.

Types of Diffraction Gratings and Points to Note

There are two main types of diffraction gratings. One transmits light and the other reflects light. Transmission gratings, which transmit light, are not often used because they require transparency over a wide range of wavelengths, but they are often used in educational settings as simple demonstrations of natural light spectroscopy, for example. Reflective gratings, another type of diffraction gratings, are gratings engraved on a metal surface, and these gratings are mainly used in spectrophotometers that require high accuracy.

When handling diffraction gratings, care must be taken to prevent dirt from adhering to it. For example, handling the grating with bare hands may cause components such as sebum to adhere to the grating and degrade its performance. In addition, in an environment prone to condensation, water may adhere to the diffraction gratings and degrade its optical characteristics. In addition, when handling intense light such as laser light, it is necessary to check the diffraction behavior in advance and understand the direction in which the light is flying so that it does not irradiate people.