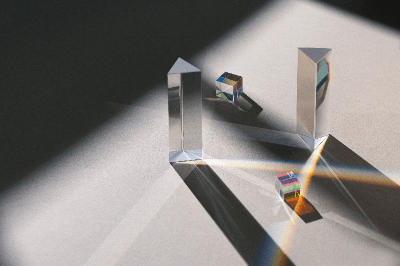

What Is a Prism Mirror?

A prism mirror is a device made of glass shaped like a triangular prism, with light-reflecting coatings applied to two sides: one on the slope and the other at a right angle.

The slope-coated type, coated on the slope, can reduce the time required for optical axis adjustment when installed at a 45° angle. The right-angle coated type, with coatings on two right-angled surfaces, can invert and reflect incoming light.

The choice of coating (e.g., broadband dielectric or metal) and base glass material depends on the intended use.

Applications of Prism Mirrors

1. Bevel Coating Type

The bevel-coated type reflects light at a 45° angle, streamlining optical axis adjustment. It’s commonly used in measurement instruments like spectrophotometers.

2. Right-Angle Configuration Surface Coated Type

This type is designed for high-speed image inversion and reflecting light parallel to the optical axis in devices like interferometers. It’s also effective in sunlight harvesting for light capture.

3. BBAR Coating Type

Prism mirrors with broadband anti-reflective (BBAR) coatings are ideal for low-power laser applications. They offer enhanced resistance to mechanical stresses, making them suitable for environments with severe acoustic and inertial loads.

Principle of Prism Mirrors

Right-angle configuration surface-coated types can disperse light into different wavelengths by leveraging the refractive index difference between air and glass. The mirror surface is coated with a material distinct from the glass to achieve this effect.

Coatings can be metallic or broadband dielectric, among others.

1. Metal Coating

Metal coatings, known for high light reflectivity, ensure total reflection of the incident light, altering its angle upon contact with the prism mirror.

2. Broadband Dielectric Coating

Broadband dielectric coatings minimize reflection and enhance light transmission into the glass. They work by coating the glass surface with materials of intermediate refractive indices to suppress unintended reflections.

While a single dielectric layer can reduce reflection, multiple layers with varying refractive indices can further improve transmittance.

Other Information on Prism Mirrors

1. Bonding Prism Mirrors

When bonding prisms, consider the coefficient of linear expansion to prevent cracking due to temperature changes. Flexible adhesives may mitigate this risk but require careful application for stable bonding.

2. Total Reflection

Total reflection occurs when light enters a medium of different refractive index, surpassing the critical angle, leading to light being entirely reflected.

3. Types of Metal Coatings

Various metals, like aluminum for the ultraviolet region and gold for the infrared region, are used for coatings. Base materials like BK7, N-BK7 for precision shapes, and synthetic fused silica for ultraviolet transmission are selected based on application requirements.

Materials with a low coefficient of linear expansion are preferable for temperature resilience.