What Is an Internal Grinder?

An internal grinder is a machine designed to grind the internal surfaces of primarily cylindrical workpieces.

Grinding is a machining process that utilizes grinding wheels.

Grinding wheels consist of tough abrasive grains, such as aluminum oxide and silicon carbide, bonded together with a bonding agent.

Grinding is not suitable for rough machining due to the shallow depth of cut compared to cutting processes.

However, it is highly effective for precision machining, delivering excellent dimensional accuracy and surface finish roughness.

Uses of Internal Grinders

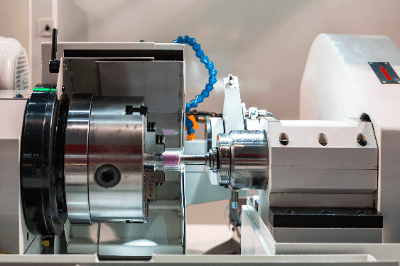

Internal grinders employ a small-diameter internal grinding wheel attached to a spindle referred to as a wheelhead.

The workpiece is secured using an external jaw chuck or an electromagnetic chuck attached to the spindle.

Internal grinders are broadly categorized into two types based on the grinding method: rotary workpiece type and planetary type.

In the workpiece rotary type, the wheel spindle and the main axis rotate relative to each other, while the grinding wheel on the wheel spindle oscillates back and forth as it cuts into the workpiece mounted on the main axis.

The planetary grinding method is employed when the workpiece is large or challenging to balance during rotation.

While rotating the wheel spindle, the spindle itself is given a planetary motion to grind along the internal surface.

To maintain the sharpness, accuracy, and shape of the grinding wheel, dressing is necessary when changing the wheel or after each grinding cycle.

Grinding wheel dressing involves placing the rotating grinding wheel on the diamond dresser installed on the machine.

Principles of Internal Grinders

In basic workpiece-turned internal grinders, the wheel head with the grinding wheel attached has a sliding mechanism relative to the spindle, allowing the grinding wheel to enter the hole.

Internal grinders are used to grind the internal surface of cylindrical shapes, but by adjusting the slide position, they can also grind the end face perpendicular to the shaft center of the hole.

Simultaneous grinding in a single process enables high-precision machining.

The hole’s diameter and length that can be ground depend on the grinding wheel’s outside diameter and the machine’s stroke.

Various bore diameters can be accommodated by selecting a grinding wheel that matches the bore diameter.

However, as bore deflection tends to be higher due to the wheel spindle’s small size, it is advisable to choose a grinding wheel with the largest possible diameter for the bore and mount it on the wheel spindle head using a short-shafted wheel spindle.

The machine can also handle stepped bore diameters, and coaxiality of the bore diameter can be achieved in a single process, ensuring high precision. Taper grinding can also be performed by angling the spindle.

When grinding workpieces with a grinding wheel, a low peripheral speed can cause abrasive grains to detach along with the bonding agent.

Typically, the wheel spindle head rotates at 2000 to 3000 rpm under standard grinding conditions to achieve the desired peripheral velocity due to the grinding wheel’s small diameter.

The spindle workpiece speed is set to maintain a peripheral speed of about 35 to 45 m/min for the grinding surface.