What Is an Air Plasma Cutting Machine?

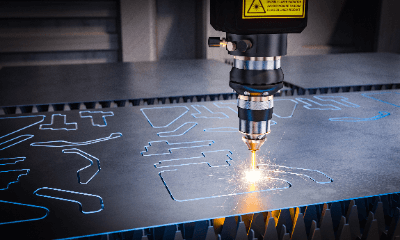

An Air Plasma Cutting Machine is a machine that uses high-temperature arc plasma to cut metals.

An Air Plasma Cutting Machine is a machine that uses high-temperature arc plasma to cut metals.

Because it is a type of plasma cutting machine and uses high-temperature arc plasma, it can cut metals efficiently. Compared to gas cutting machines and plasma cutting machines, they can cut many types of metals, including hard metals such as stainless steel, aluminum, brass, and iron.

They are also widely used in large factories, automobile repair shops, and shipyards. When metals need to be cut, Air Plasma Cutting Machines are essential in many industries because of their high efficiency.

Like plasma cutting machines, they require advanced technology, but when operated correctly, they are efficient.

Safety must also be taken into consideration, and it is important to wear appropriate safety equipment such as safety glasses and gloves during operation.

Uses of Air Plasma Cutting Machine

Air Plasma Cutting Machines are primarily used for cutting metal, mainly in processing plants. Unlike Plasma Cutting Machines, Air Plasma Cutting Machines use high-pressure air and can cut many metals, including hard metals, aluminum, brass, and iron.

They are used for cutting steel frames and steel products, processing metals at construction sites, and cutting metals in automobile and ship repair shops. Additionally, they are widely used in a variety of fields, including pipelines, steel mills, and the aerospace industry.

Air Plasma Cutting Machines, like Plasma Cutting Machines, are used manually and are effective for cutting thick plates, although they are not suitable for finish cutting as the cut surface tends to be somewhat rough.

Principle of Air Plasma Cutting Machine

Air Plasma Cutting Machines are composed of a plasma arc that melts and cuts metal by means of high-temperature arc heat and plasma flow.

The plasma arc is generated by applying high-frequency electricity between the electrode at the tip of the torch and the object to be cut. The electrode at the tip of the torch is heated by the electricity flow, and the surrounding air molecules are ionized and become plasma.

The plasma arc is maintained by the plasmaized gas and becomes extremely hot (approx. 20,000°C). This high-temperature plasma arc melts the metal, which is then blown away by high-pressure air for cutting.

Air Plasma Cutting Machines are also available in a water injection type equipped with an internal cooling system. Since the area around the plasma arc becomes very hot, cooling water is injected to release the heat, thereby extending the life of the torch.

The water injection type also has the advantage of improving cutting accuracy because the heating caused by the plasma arc is reduced.

Other Information on Air Plasma Cutting Machine

Advantages of Air Plasma Cutting Machine

Air Plasma Cutting Machines have the following four advantages: it can cut plates up to 100 mm thick, can cut materials that cannot be cut by gas cutting such as stainless steel and aluminum alloy, can cut curves with relative ease, has low running costs, is simple to operate, and is safe.

The advantages are as follows:

1. High precision cutting

Since plasma arc is used, the material is melted by heat and no residual stress is generated on the cut surface. Therefore, the cut surface is smooth and clean. Cutting can also be performed using a CNC machine, which enables high-precision cutting processing.

2. Energy saving

The material melted by the heat generated by the plasma arc is discharged at high speed. This reduces power consumption and saves energy.

3. High flexibility

During cutting, the quality of the cut surface can be changed by feeding cleaner gas between the torch and the object to be cut. This allows appropriate cutting conditions to be set when cutting sheet metal of different materials and thicknesses.

4. Low-cost introduction

Compared to other cutting technologies, the cost of equipment is low, making it possible to introduce the system at a low cost. Also, the consumables used are inexpensive, so running costs can be kept low.